Abstract

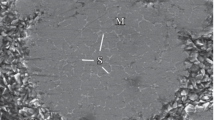

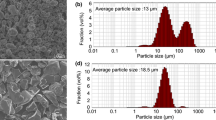

The effect of the preliminary deformation and heat treatment by all-round forging under conditions of short-term high-temperature creep on the microstructure and mechanical properties of a composite material based on a high-strength aluminum alloy of the Al–Cu–Mg–Zn system (Al7075) strengthened with SiC particles (10 wt %) is investigated. The most effective regime of short-term high-temperature creep is established experimentally. It is found that an avalanche-like increase in the rate of relative deformation occurs upon heating to temperatures above 500°C. This increase is due to the local appearance of a liquid phase at the boundaries between the needle-like particles of the S-phase and an Al based solid solution in the composite matrix in accordance with the eutectic transformation α-Al + S(Al2CuMg) → L. After deformation and heat treatment, reinforcing SiC particles are redistributed and the structure of the composite is transformed from a cellular to a uniform configuration. At the same time, the micromechanical properties are leveled over the volume of the composite. The maximum value of the resistance to deformation in the axial compression test increases.

Similar content being viewed by others

REFERENCES

E. N. Kablov, B. V. Shchetanov, D. V. Grashchenkov, A. A. Shavnev, and A. N. Nyafkin, “Metal-matrix composite materials based on Al–SiC,” AMIT, No. S, 373–380 (2012).

A. A. Shavnev, V. V. Berezovskii, and Yu. A. Kurganova, “Features of the use of a structural metal composite material based on an aluminum alloy reinforced with SiC particles. Part 1 (review),” Novosti Materialovedeniya. Nauka i Tekhnika, No. 3, 3–10 (2015).

A. A. Shavnev, V. V. Berezovskii, and Yu. A. Kurganova, “Features of the use of a structural metal composite material based on an aluminum alloy reinforced with SiC particles. Part 2 (review),” Novosti Materialovedeniya. Nauka i Tekhnika, No. 3, 11–17 (2015).

E. A. Stoyakina, E. I. Kurbatkina, V. N. Simonov, D. V. Kosolapov, and A. V. Gololobov, “Mechanical properties of aluminum-matrix composites reinforced with SiC particles, depending on the matrix alloy (review),” Trudy VIAM, No. 2, 62–73 (2018).

D. B. Miracle, “Metal matrix composites – From science to technological significance,” Compos. Sci. Technol. 65, No. 15–16, 2526–2540 (2005). https://doi.org/10.1016/j.compscitech.2005.05.027

V. V. Vani and S. K. Chak, “The effect of process parameters in aluminum metal matrix composites with powder metallurgy,” Manuf. Rev. 5, 7 (2018).

E. I. Kurbatkina, A. A. Shavnev, D. V. Kosolapov, and A. V. Gololobov, “Features of heat treatment of composite materials with an aluminum matrix (review),” Trudy VIAM, No. 11, 82–97 (2017).

E. I. Kurbatkina, D. V. Kosolapov, A. V. Gololobov, and A. A. Shavnev, “Study of the structure and properties of a metallic composite material of the Al–Zn–Mg Cu/SiC system,” Tsvetn. Met., No. 1, 40–45 (2019).

J. Čadek, K. Kuchařová, and S. J. Zhu, “High temperature creep behaviour of an Al–8.5Fe–1.3V–1.7Si alloy reinforced with silicon carbide particulates,” Mater. Sci. Eng., A 283, No. 1–2, 172–180 (2000).

J. Čadek, K. Kuchařová, and S. J. Zhu, “Transition from athermal to thermally activated detachment of dislocations from small incoherent particles in creep of an Al–8.5Fe–1.3V–1.7Si alloy reinforced with silicon carbide particulates,” Mater. Sci. Eng., A 297, Nos. 1–2, 176–184 (2000).

Z. Y. Ma and S. C. Tjong, “High-temperature creep behaviour of SiC particulate reinforced Al–Fe–V–Si alloy composite,” Mater. Sci. Eng., A 278, Nos. 1–2, 5–15 (2000).

M. S. Kishchik, A. D. Kotov, A. A. Kishchik, A. V. Mikhailovskaya, D. O. Demin, and S. A. Aksenov, “The effect of multidirectional forging on the deformation and microstructure of the Al–Mg alloy,” Phys. Met. Metallogr. 121, No. 6, 597–603 (2020).

A. A. Kishchik, M. S. Kishchik, A. D. Kotov, and A. V. Mikhailovskaya, “Effect of multidirectional forging on the microstructure and mechanical properties of the Al–Mg–Mn–Cr alloy,” Phys. Met. Metallogr. 121, No. 5, 489–494 (2020).

D. Božić, M. Vilotijević, V. Rajković, and Ž. Gnjidić, “Mechanical and fracture behaviour of a SiC-particle-reinforced aluminum alloy at high temperature,” Mater. Sci. Forum 494, 487–492 (2005).

M. Y. Wu and O. D. Sherby, “Superplasticity in a silicon carbide whisker reinforced aluminum alloy,” Scr. Metall. 18, No. 8, 773–776 (1984).

G. González-Doncel and O. D. Sherby, “Tensile ductility and fracture of superplastic Aluminum–SiC composites under thermal cycling conditions,” Metall. Mater. Trans. A 27, No. 9, 2837–2842 (1996).

A. Yu. Larichkin, K. V. Zakharchenko, B. V. Gorev, and V. I. Kapustin, “Experimental modeling of technological process of pure aluminum alloy (Al–Zn–Mg–Cu) structural elements forming under creep,” Obrabotka Metallov (Tekhnologiya, Oborudovanie, Instrumenty), No. 1, 6–15 (2016).

H. Luo, W. Li, C. Li, and M. Wan, “Investigation of creep-age forming of aluminum lithium alloy stiffened panel with complex structures and variable curvature,” Int. J. Adv. Manuf. Technol. 91, Nos. 9–12, 3265–3271 (2017).

J. R. Pickens, T. J. Langan, R. O. England, and M. Liebson, “A study of the hot-working behavior of SiC−Al alloy composites and their matrix alloys by hot torsion testing,” Metall. Mater. Trans. A 18, No. 2, 303–312 (1987).

A. Razaghian, D. Yu, and T. Chandra, “Fracture behaviour of a SiC-particle-reinforced aluminium alloy at high temperature,” Compos. Sci. Technol. 58, No. 2, 293–298 (1998).

Q. M. Azpen, B. T. H. T. Baharudin, S. Shamsuddin, and F. Mustapha, “Reinforcement and hot workability of aluminium alloy 7075 particulate composites: A review,” J. Eng. Sci. Technol. 13, No. 4, 1034–1057 (2018).

D. I. Kryuchkov and A. V. Nesterenko, “A review of experimental studies of creep behavior and superplasticity in a discontinuous sic aluminum-matrix composites,” Obrabotka Metallov (Tekhnologiya, Oborudovanie, Instrumenty) 22, No. 2, 130–157 (2020).

S. V. Smirnov, D. I. Kryuchkov, A. V. Nesterenko, I. M. Berezin, D. I. Vichuzhanin, “Experimental study of short-term unsteady creep of an aluminum-matrix composite under uniaxial compression,” VPNIPU. Mekhanika, No. 4, 98–105 (2018).

N. B. Pugacheva, N. S. Michurov, E. I. Senaeva, and T. M. Bykova, “Structure and thermophysical properties of aluminum-matrix composites,” Phys. Met. Metallogr. 117, No. 11, 1144–1151 (2016).

N. B. Pugacheva, N. S. Michurov, and T. M. Bykova, “Structure and properties of the Al/SiC composite material,” Phys. Met. Metallogr. 117, No. 6, 634–640 (2016).

N. B. Pugacheva, I. Yu. Malygina, N. S. Michurov, E. I. Senaeva, and N. P. Antenorova, “Effect of heat treatment on the structure and phase composition of aluminum matrix composites containing silicon carbide,” Diag., Resour. Mech. Mater. Struct., No. 6, 28–36 (2017).

B. N. Arzamasov and T. V. Solov’ev, Handbook on Structural Materials (MSTU after N. E. Bauman, Moscow, 2005) [in Russian].

ACKNOWLEDGMENTS

We are grateful to A.S. Smirnov, Cand. Sci. (Tech.), for carrying out the experiments.

Funding

This study was supported by Program of Fundamental Research of State Academies of Sciences, topic no. AAAA-A18-118020790145-0. The equipment of Center for Collective Use Plastometriya at the Institute of Mechanical Engineering, Ural Branch, Russian Academy of Sciences, was used when performing the tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Kadkin

Rights and permissions

About this article

Cite this article

Kryuchkov, D.I., Nesterenko, A.V., Smirnov, S.V. et al. Influence of All-Round Forging under Short-Term Creep Conditions on the Structure and Mechanical Properties of the Al7075/10SiCp Composite with an Aluminum Matrix. Phys. Metals Metallogr. 122, 981–990 (2021). https://doi.org/10.1134/S0031918X21100069

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21100069