Abstract

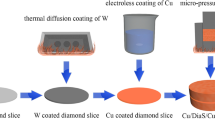

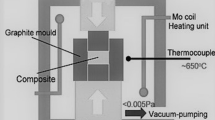

A composite material with a high thermal conductivity is obtained by capillary infiltration of copper into a bed of diamond particles of 400 μm size, the particles having been pre-coated with tungsten. The measured thermal conductivity of the composite decreases from 910 to 480 W m−1 K−1 when the coating thickness is increased from 110 to 470 nm. Calculations of the filler/matrix thermal boundary resistance R and the thermal conductivity of the coating layer λ i using differential effective medium, Lichtenecker’s and Hashin’s models give similar numerical values of R and λ i ≈ 1.5 W m−1 K−1. The minimal thickness of the coating h ∼ 100 nm necessary for ensuring production of a composite while maximizing its thermal conductivity, is of the same order as the free path of the heat carriers in diamond (phonons) and in copper (electrons). The heat conductance of the diamond/tungsten carbide coating/copper interface when h is of this thickness is estimated as (0.8–1) × 108 W m−2 K−1 and is at the upper level of values characteristic for perfect dielectric/metal boundaries.

Similar content being viewed by others

References

S. V. Kidalov and F. M. Shakhov, Materials 2, 2467 (2009).

High Thermal Conductivity Materials, Ed. by S. L. Shinde and J. S. Goela (Springer, New York, 2006).

Synthetic CVD Diamond Products from Element Six; http://www.e6cvd.com.

ExtreMat-Heat Sink Materials; http://www.extremat.org/heat-sink-materials?Edition=en.

K. Hanada, K. Matsuzaki, and T. Sano, J. Mater. Process. Technol. 153–154, 514 (2004).

J. Barcena, J. Maudes, M. Vellvehi, X. Jorda, I. Obieta, C. Guraya, L. Bilbao, C. Jimenez, C. Merveille, and J. Coleto, Acta Astronaut. 62, 422 (2008).

K. Yoshida and H. Morigami, Microelectron. Reliab. 44, 303 (2004).

T. Schubert, L. Ciupinski, W. Zielinski, A. Michalski, T. Weibgarber, and B. Kieback, Scr. Mater. 58, 263 (2008).

L. Weber and R. Tavangar, Scr. Mater. 57, 988 (2007).

L. Weber and R. Tavangar, Adv. Mater. Res. 59, 111 (2009).

A. M. Abyzov, S. V. Kidalov, and F. M. Shakhov, J. Mater. Sci. 46, 1424 (2011).

Surface Properties of Melts and Solids and Their Use in Materials Science, Ed. by Yu. V. Naidich (Naukova Dumka, Kiev, 1991) [in Russian].

F. Cardarelli, Materials Handbook (Springer, London, 2008), Chaps. 3, 10.

V. G. Chuprina, Powder Metall. Met. Ceram. 31(7), 578 (1992).

V. G. Chuprina, Powder Metall. Met. Ceram. 31(8), 687 (1992).

A. M. Abyzov, S. V. Kidalov, and F. M. Shakhov, Materialovedenie, No. 5, 24 (2008).

L. C. Davis and B. E. Artz, J. Appl. Phys. 77, 4954 (1995).

V. B. Efimov and L. P. Mezhov-Deglin, Physica B (Amsterdam) 263–264, 745 (1999).

B. Feng, Z. Li, and X. Zhang, Thin Solid Films 517, 2803 (2009).

M. Battabyal, O. Beffort, S. Kleiner, S. Vaucher, and L. Rohr, Diamond Relat. Mater. 17, 1438 (2008).

E. T. Swartz and R. O. Pohl, Rev. Mod. Phys. 61, 605 (1989).

R. Prasher, J. Appl. Phys. 100, 064302 (2006).

D. P. Hasselman and L. F. Johnson, J. Compos. Mater. 21, 508 (1987).

R. Tavangar, J. M. Molina, and L. Weber, Scr. Mater. 56, 357 (2007).

K. Lichtenecker, Phys. Z. 10(25), 1005 (1909).

V. I. Loginov and V. G. Kucherov, J. Appl. Mech. Tech. Phys. 32, 413 (1991).

A. M. Dykhne, Sov. Phys. JETP 32(1), 63 (1970).

Z. Hashin, J. Appl. Phys. 89, 2261 (2001).

Z. Hashin and S. Shtrikman, J. Appl. Phys. 33, 3125 (1962).

A. M. Abyzov, S. V. Kidalov, and F. M. Shakhov, Phys. Solid State 53(1), 48 (2011).

Handbook of Physical Quantities, Ed. by I. S. Grigoriev and E. Z. Meilikhov (Energoatomizdat, Moscow, 1991; CRC Press, Boca Raton, Florida, 1997), p. 340.

K. Chu, Z. Liu, C. Jia, H. Chen, X. Liang, W. Gao, W. Tian, and H. Guo, J. Alloys Compd. 490, 453 (2010).

C.-W. Nan, R. Birringer, D. R. Clarke, and H. Gleiter, J. Appl. Phys. 81, 6692 (1997).

A. Yu. Klokov, D. F. Aminev, A. I. Sharkov, V. G. Ral’chenko, and T. I. Galkina, Phys. Solid State 50(12), 2263 (2008).

R. J. Stoner and H. J. Maris, Phys. Rev. B: Condens. Matter. 48, 16373 (1993).

C. B. Gundrum, D. G. Cahill, and R. S. Averback, Phys. Rev. B: Condens. Matter 72, 245426 (2005).

W. Park, D. V. Baxter, S. Steenwyk, I. Moraru, W. P. Jr. Pratt, and J. Bass, Phys. Rev. B: Condens. Matter 62, 1178 (2000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.M. Abyzov, S.V. Kidalov, F.M. Shakhov, 2012, published in Fizika Tverdogo Tela, 2012, Vol. 54, No. 1, pp. 196–201.

The article was translated by the authors.

Rights and permissions

About this article

Cite this article

Abyzov, A.M., Kidalov, S.V. & Shakhov, F.M. Filler-matrix thermal boundary resistance of diamond-copper composite with high thermal conductivity. Phys. Solid State 54, 210–215 (2012). https://doi.org/10.1134/S1063783412010027

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783412010027