Abstract

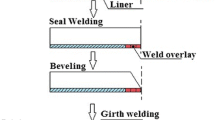

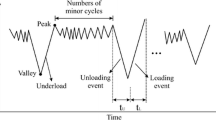

Welding of branch connections on gas pipelines at full line pressure is frequently an operational necessity. Weld parameters must be selected so that heat inputs are low enough to avoid burnthrough yet not so low that hydrogen-assisted cold cracking occurs. Current techniques rely on the observation that burnthrough does not occur if peak temperatures on the inner surface are kept below 980°C. At these temperatures, rate-dependent flow is the dominant mechanism. The problem is one of creep rupture occurring at temperatures in excess of 980°C with times of the order of seconds. Material constitutive models for the analysis of welding must include both rate-dependent and rate-independent plastic flow as well as the effects of phase transformations. Material properties at elevated temperatures are usually not available for pipeline steels and must be extrapolated from values at lower temperatures. An exploratory study using 3D thermal-mechanical finite element analysis of welding on pressurized vessels is presented and includes comparisons with experiment. The agreement is encouraging. The material failure does occur in appropriate locations but the predictions are generally overconservative. Estimated material properties, especially damage and rupture properties at high temperatures could be improved.

Similar content being viewed by others

References

Andersson, B.A.B. (1978). Thermal stresses in a submerged-arc welded joint considering phase transformations. Journal of Engineering Materials and Technology 100, 356–362.

Baumeister, T., Avallone, E.A. and Baumeister III, T. (1978). Mark's Standard Handbook for Mechanical Engineers, 8th ed., McGraw-Hill, 4–69.

Boyer, H.E. (1988). Atlas of creep and stress-rupture curves. ASM International, 3.3–3.4, 19.10.

Bruce, W.A., Mishler, H.D. and Kiefner, J.F. (1993). Repair of pipelines by direct deposition of weld metal. Final Report, EWI Project Nos. J7200, J7213, Edison Welding Institute.

McDill, J.M.J., Goldak, J.A., Oddy, A.S. and Bibby, M.J. (1987). Isoparametric quadrilaterals and hexahedrons for mesh grading algorithms. Communications in Applied Numerical Methods 3, 155–163.

McDill, J.M.J., Oddy, A.S. and Goldak, J.A. (1992). Comparing 2D plane strain and 3D analyses of residual stresses in welds. Proceedings 3rd International Conference on Trends in Welding Research, Gatlinburg, 105–108.

Dubost, B., Bouet-Griffon, M., Jeanmart, P.H. and Homette, M.O. (1988). Prediction and minimization of residual stresses in quenched aluminum alloy cylinders. International Conference on Residual Stresses 2, Nancy, France, 581–586.

Goldak, J.A. and Oddy, A.S. (1992). Finite element analysis of welding on fluid-filled, pressurized vessels. Proceedings 3rd International Conference on Trends in Welding Research, Gatlinburg, 45–50.

Grong, O. (1994). Metallurgical modelling of welding. Institute of Materials, London, 509–523.

Hall, F.R. and Hayhurst, D.R. (1991). Continuum damage mechanics modelling of high temperature deformation and failure in a pipe weldment. Proceedings of the Royal Society of London A, 433 383–403.

Harste, K., Suzuki, T. and Schwerdtfeger, K. (1992). Thermomechanical properties of steel: viscoplasticity of γ iron and γ Fe-C alloys. Materials Science and Technology 8, 23–33.

Klueh, R.L. (1983). Heat-to-heat variations in creep-rupture properties of annealed 2 1/4 Cr — 1 Mo Steel. Journal of Pressure Vessel Technology 105,4, 320–328.

Kojic, M. and Bathe, K.J. (1987). The Effective-stress-function algorithm for thermo-elasto plasticity and creep. International Journal for Numerical Methods in Engineering 24, 1509–1532.

Leckie, F.A. (1986). The micro-and macromechanics of creep rupture. Engineering Fracture Mechanics 25,5/6, 505–521.

Lienhard, J.A. (1988). Burnout on cylinders. Journal of Heat Transfer 110, 1271–1286.

Oddy, A.S., Goldak, J.A. and McDill, J.M.J. (1989). Transformation effects in the 3D finite element analysis of welds. Proceedings 2nd International Conference on Trends in Welding Research, Gatlinburg, 97–101.

Oddy, A.S., McDill, J.M.J. and Goldak, J.A. (1990). Consistent strain fields in 3D finite element analysis of welds. Journal of Pressure Vessel Technology 112,3, 309–311.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Oddy, A., McDill, J. Burnthrough prediction in pipeline welding. International Journal of Fracture 97, 249–261 (1999). https://doi.org/10.1023/A:1018369304971

Issue Date:

DOI: https://doi.org/10.1023/A:1018369304971