Abstract

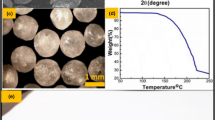

The influence of different porosity levels of magnesium gasars manufactured with the use of the Bridgman-type directional solidification method on their compression behavior was investigated. The cross-section structure perpendicular to the height of the produced gasars ingots was characterized using X-ray computed tomography (CT). These results indicated that gasars with porosities of 30%, 36%, 39%, and 48% were obtained, and those with porosities of 30% and 36% had a homogenous porosity distribution and the uniform diameter of the pores. Compression tests were carried out to compare the mechanical properties of the manufactured gasars vs cast porosity-free magnesium. The gasar with 30% porosity achieved the highest compressive strength \(\left({R}_{{\text{c}}}\right)\) of all the tested gasars ingots, which was 107 MPa. In addition, when the compressive strength was calculated for the sample cross-section, excluding its porosity, the modified compressive strength \(\left({{\text{MR}}}_{{\text{c}}}\right)\) of 152 MPa was obtained for the gasar with 30% porosity, and it was about 8.5% higher than the compressive strength of monolithic porosity-free magnesium. Moreover, taking into account the density of tested material, the gasar with 30% porosity achieved the highest specific strength and the highest energy absorption capacity among all the tested magnesium gasars. For the examined materials, numerical simulations of the compression behavior were performed, and the results obtained are discussed in terms of the mechanism controlling the strengthening process in a high-porosity magnesium with directional oriented structure.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Shapovalov V, Serdiuk N. Izvestiya Vuzov. Tsvetnaya Metallurgiya. 1980;2:90–3.

Shapovalov V. Method for manufacturing porous articles. US patent: 5181549, Jan. 26, 1993.

Shapovalov V. MRS Online Proceedings Library (OPL), Symposium R – Porous & Cellular Materials for Structural Applications. 1998; https://doi.org/10.1557/PROC-521-121.

Shapovalov V. Formation of ordered gas-solid structures VIA solidification in metal-hydrogen systems. MRS Online Proc Libr. 1998. https://doi.org/10.1557/PROC-521-281.

Shapovalov V. Prospective manufacture and aircraft applications of cast metal porous materials, state of the art in cast metal matrix composites in the next millennium, TMS Fall Meeting. St. Louis, MD. 18–20 October 2000, p. 291–302.

Shapovalov V. Prospective applications of gas-eutectic porous materials (Gasars) in USA. Mater Sci Forum. 2007. https://doi.org/10.4028/www.scientific.net/msf.539-543.1183.

Nakajima H. Invariant reaction of liquid → solid + gas. Gas-evolution crystallization reaction. Mater Trans. 2001. https://doi.org/10.2320/matertrans.42.1827.

Nakajima H. Fabrication of lotus-type porous metals, intermetallic compounds and semiconductors. Mater Sci Forum. 2005. https://doi.org/10.4028/www.scientific.net/MSF.502.367.

Nakajima H. Fabrication, properties and application of porous metals with directional pores. Prog Mater Sci. 2007. https://doi.org/10.1016/j.pmatsci.2006.09.001.

Nakajima H. Fabrication, properties, and applications of porous metals with directional pores. Proc Jpn Acad Ser B. 2010;86(9):884–99. https://doi.org/10.2183/pjab.86.884.

Nakahata T, Nakajima H. Fabrication of lotus-type porous silicon by unidirectional solidification in hydrogen. Mater Sci Eng, A. 2004. https://doi.org/10.1016/j.msea.2004.07.004.

Shapovalov V. Legirovaniye vodorodom. Dnepropetrovsk: Zhurfond. 2013, p. 385 (in Russian).

Shapovalov V, Boyko L. Gasar—a new class of porous materials. Adv Eng Mater Res News. 2004. https://doi.org/10.1002/adem.200405148.

Drenchev L, Sobczak JJ. Gasars—advanced porous materials by knowledge-based design. MTI&FRI; 2009.

Drenchev L, Sobczak JJ, Malinov S, Sha W. Gasars: a class of metallic materials with ordered porosity. Mater Sci Technol. 2006. https://doi.org/10.1179/174328406X118302.

Sobczak JJ, Sobczak N, Drenchev L. Metals with directed porosity. AGH University of Science and Technology Press. 2020 (in Polsih).

Sobczak N, et al. Final report of ESA project “New generation light-weight materials for advanced space applications”, Contract No: 4000109468/13/NL/Cbi, 2014–2017.

Burbelko A, Garzeł G, Sobczak J. Thermodynamic analysis of the effect of pressure on three-phase equilibrium “liquid-HCP-gas” in the Mg-H system. In: XVII konferencja sprawozdawcza Komitetu Metalurgii PAN. 2021, p. 531–549 (in Polish).

Bul’skii MT, Kalashnikov AG, Beloglovskii MS. On the structure of rimmed-steel ingots. Metallurgist. 1958. https://doi.org/10.1007/BF01087578.

Watanabe S, Asano K, Ohashi T. Study on the structures of semi-killed steel ingots. Trans ISIJ. 1969; https://doi.org/10.2355/isijinternational1966.9.1.

Simone AE, Gibson LJ. The tensile strength of porous copper made by the gasar process. Acta Mater. 1996. https://doi.org/10.1016/1359-6454(95)00278-2.

Zhou CX, Liu Y, Zhang HW, Chen X, Li YX. Fabrication of lotus-type porous Mg–Mn alloys by metal/gas eutectic unidirectional solidification. Trans Nonferrous Metals Soc China. 2020. https://doi.org/10.1016/S1003-6326(20)65316-X.

https://imagej.nih.gov. Accessed 17 Jul 2023.

Ashby MF, Gibson LJ. Cellular solids: structure and properties. 2nd ed. Cambridge: Cambridge University Press; 1997.

https://discover.solidworks.com. Accessed 17 Jul 2023.

Patterson JB, Morris EC. Measurement of absolute water density, 1 to 40°C. Metrologia. 1994. https://doi.org/10.1088/0026-1394/31/4/001.

Mayama T, Tane M, Tadano Y. Superior energy absorption in porous magnesium: contribution of texture development triggered by intra-granular misorientations. Acta Mater. 2019. https://doi.org/10.1016/j.actamat.2018.11.037.

Wang F, Ma DX, Zhang J, Bogner S, Bührig-Polaczek A. A high thermal gradient directional solidification method for growing superalloy single crystals. J Mater Process Technol. 2014;214(12):3112–21. https://doi.org/10.1016/j.jmatprotec.2014.07.020.

Kucharczyk A, Naplocha K, Kaczmar JW, Dieringa H, Kainer KU. Current status and recent developments in porous magnesium fabrication. Adv Eng Mater. 2018. https://doi.org/10.1002/adem.201700562.

Stanev L, Drenchev B, Yotov A, Lazarova R. Compressive properties and energy absorption behaviour of AlSi10Mg open-cell foam. J Mater Sci Technol. 2014;22(1):44–53.

Boczkal G, Janoska M, Setman D, Schafler E, Dlugosz P, Darlak P. Magnesium gasar as a potential monolithic hydrogen absorbent. Int J Hydrogen Energy. 2021. https://doi.org/10.1016/j.ijhydene.2021.01.166.

Liu Y, Li XY, Wan J, Zhang HW. Evaluation of porosity in lotus-type porous magnesium fabricated by metal/gas eutectic unidirectional solidification. Mater Sci Eng, A. 2005. https://doi.org/10.1016/j.msea.2005.03.107.

Zhou C, Liang G, Liu Y, Zhang H, Chen X, Li Y. Pore structure of porous Mg-1Mn-xZn alloy fabricated by metal–gas eutectic unidirectional solidification. J Magnes Alloys. 2022. https://doi.org/10.1016/j.jma.2021.03.026.

Komissarchuk O, Xu Z, Hao H, Zhang X, Karpov V. Pore structure and mechanical properties of directionally solidified porous aluminum alloys. China Foundry. 2014;11(1):1–7.

Simone AE, Gibson LJ. The compressive behaviour of porous copper made by the GASAR process. J Mater Sci. 1997. https://doi.org/10.1023/A:1018573904809.

Kováčik J. The tensile behaviour of porous metals made by gasar process. Acta Mater. 1998. https://doi.org/10.1016/S1359-6454(98)00199-2.

Park GH, Kim JT, Park HJ, Kim YS, Jeong HJ, Lee N, Seo Y, Suh J-Y, Son H-T, Wang W-M, Park JM, Kim KB. Development of lightweight MgLiAl alloys with high specific strength. J Alloy Compd. 2016. https://doi.org/10.1016/j.jallcom.2016.04.109.

Dobrzański LA. The fundamentals of materials science. 2nd ed. Warsaw, Poland: WNT; 2006. (in Polish).

Yu H, Xin Y, Wang M, Liu Q. Hall-Petch relationship in Mg alloys: a review. J Mater Sci Technol. 2018;34(2):248–56. https://doi.org/10.1016/j.jmst.2017.07.022.

Zhou CX, Liu Y, Zhang HW, Chen X, Li YX. Compressive and corrosion properties of lotus-type porous Mg-Mn alloys fabricated by unidirectional solidification. Metall Mater Trans A. 2020. https://doi.org/10.1007/s11661-020-05732-1.

Sułkowski B, Chulist R. Twin-induced stability and mechanical properties of pure magnesium. Mater Sci Eng A. 2019;749:89–95. https://doi.org/10.1016/j.msea.2019.01.118.

Guo H, Tian X, Fan J, Zhang H, Zhang Q, Li W, Dong HB, Xu BS. The compressive behavior and energy absorption performance of nanocrystalline porous magnesium fabricated by hydrogenation-dehydrogenation and spark plasma sintering technique. J Alloy Compd. 2023. https://doi.org/10.1016/j.jallcom.2021.158698.

Yang DH, Yang SR, Hui W, Ma A, Jiang JH, Chen JQ, Wang DL. Compressive properties of cellular Mg foams fabricated by melt-foaming method. Mater Sci Eng A. 2010. https://doi.org/10.1016/j.msea.2010.05.017.

Acknowledgements

This research was supported by the National Science Centre of Poland within OPUS 16 Program, Project no. 2018/31/B/ST8/01172.

Funding

This study was supported by Narodowe Centrum Nauki, 2018/31/B/ST8/01172, Jerzy Józef Sobczak.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Janus, K., Liu, Y., Drenchev, L. et al. Compression behavior of cast high-porosity magnesium with directionally oriented structure. Archiv.Civ.Mech.Eng 24, 55 (2024). https://doi.org/10.1007/s43452-024-00870-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-024-00870-4