Abstract

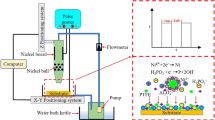

In this work, multicomponent PEEK coatings with PTFE particles and TiN nanoparticles were developed on Ti-6Al-4V alloy substrates using electrophoretic deposition (EPD) and post-EPD heat treatment. Three different polyelectrolytes involving chitosan, PAZO and sodium alginate were used to enable the co-deposition of all particles on one electrode. All polyelectrolytes were effective and enabled coating deposition through electrosteric stabilization of suspension. The EPD mechanism consisted of the adsorption of the dispersant on the surface of the particles and the imparting of a positive (chitosan) or negative (PAZO, sodium alginate) charge. Heat treatment densified the coatings but also caused microcrack formation in the coating with chitosan, shrinkage of the polymers in the coating with PAZO, and open porosity in the coating with sodium alginate. Coatings obtained from suspension with chitosan showed excellent adhesion strength and scratch resistance, higher that those deposited from suspensions containing PAZO or alginate. The introduction of TiN and PTFE particles into the PEEK matrix resulted in a simultaneous reduction of the friction coefficient and wear rate of the titanium alloy in the case of coatings with chitosan and alginate. These coatings are promising for improving the wear and friction properties of titanium alloys.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Corni I, Ryan MP, Boccaccini AR. Electrophoretic deposition: from traditional ceramics to nanotechnology. J Eur Ceram. 2008;28:1353–67. https://doi.org/10.1016/j.jeurceramsoc.2007.12.011.

Ishihara T, Sato K, Takita Y. Electrophoretic deposition of Y2O3-stabilized ZrO2 electrolyte films in solid oxide fuel cells. J Am Ceram. 1996;79:913–9. https://doi.org/10.1111/j.1151-2916.1996.tb08525.x.

Besra L, Zha S, Liu M. Preparation of NiO-YSZ/YSZ bi-layers for solid oxide fuel cells by electrophoretic deposition. J Power Sources. 2006;160:207–14. https://doi.org/10.1016/j.jpowsour.2005.12.090.

Ferrari B, Moreno R. Electrophoretic deposition of aqueous alumina slips. J Eur Ceram. 1997;77:549–56. https://doi.org/10.1016/S0955-2219(96)00113-6.

Moreno R, Ferrari B. Effect of the slurry properties on the homogeneity of alumina deposits obtained by aqueous electrophoretic deposition. Mater Res Bull. 2000;35:887–97. https://doi.org/10.1016/S0025-5408(00)00288-9.

Abolmaali SB, Talbot JB. Synthesis of superconductive thin films of YBa2Cu3O7-x by a nonaqueous electrodeposition process. J Electrochem Soc. 1993;140:443–5. https://doi.org/10.1149/1.2221065.

Nicholson PS, Sarkar P, Haung X. Electrophoretic deposition and its use to synthesize ZrO2/Al2O3 micro-laminate ceramic/ceramic composites. J Mater Sci. 1993;28:6274–8. https://doi.org/10.1007/BF01352183.

Farrokhi-Rad M, Ghorbani M. Electrophoretic deposition of titania nanoparticles in different alcohols: kinetics of deposition. J Am Ceram. 2011;94:2354–61. https://doi.org/10.1111/j.1551-2916.2011.04401.x.

Ammam M. Electrophoretic deposition under modulated electric fields: a review. RSC Adv. 2012;2:7633–46. https://doi.org/10.1039/C2RA01342H.

Chen Q, Cordero-Arias L, Roether JA, Cabanas-Polo S, Virtanen S, Boccaccini AR. Alginate/Bioglass® composite coatings on stainless steel deposited by direct current and alternating current electrophoretic deposition. Surf Coat Technol. 2013;233:49–56. https://doi.org/10.1016/j.surfcoat.2013.01.042.

López I, Vázquez A, Hernández-Padrón GH, Gómez I. Electrophoretic deposition (EPD) of silver nanoparticles and their application as surface-enhanced Raman scattering (SERS) substrates. Appl Surf Sci. 2013;280:715–9. https://doi.org/10.1016/j.apsusc.2013.05.048.

Hu S, Li W, Finklea H, Liu X. A review of electrophoretic deposition of metal oxides and its application in solid oxide fuel cells. Adv Colloid Interface Sci. 2020;276: 102102. https://doi.org/10.1016/j.cis.2020.102102.

Wang C, Ma J, Cheng W. Formation of polyetheretherketone polymer coating by electrophoretic deposition method. Surf Coat Technol. 2003;173:271–5. https://doi.org/10.1016/S0257-8972(03)00626-1.

Zhitomirsky I, Petric A. Electrophoretic deposition of ceramic materials for fuel cell applications. J Eur Ceram. 2000;20:2055–61. https://doi.org/10.1016/S0955-2219(00)00098-4.

Grandfield K, Zhitomirsky I. Electrophoretic deposition of composite hydroxyapatite–silica–chitosan coatings. Mater Charact. 2008;59:61–7. https://doi.org/10.1016/j.matchar.2006.10.016.

Mohan L, Durgalakshmi D, Geetha M, Sankara Narayanan TSN, Asokamani R. Electrophoretic deposition of nanocomposite (HAp+TiO2) on titanium alloy for biomedical applications. Ceram Int. 2012;38:3435–43. https://doi.org/10.1016/j.ceramint.2011.12.056.

Corni I, Neumann N, Novak S, König K, Veronesi P, Chen Q, Ryan MP, Boccaccini AR. Electrophoretic deposition of PEEK-nano alumina composite coatings on stainless steel. Surf Coat Technol. 2009;203:1349–59. https://doi.org/10.1016/j.surfcoat.2008.11.005.

Zhang J, Wen Z, Zhao M, Li G, Dai C. Effect of the addition CNTs on performance of CaP/chitosan/coating deposited on magnesium alloy by electrophoretic deposition. Mater Sci Eng C. 2016;58:992–1000. https://doi.org/10.1016/j.msec.2015.09.050.

Huang Y, Sarkar DK, Chen X. Superhydrophobic nanostructured ZnO thin films on aluminum alloy substrates by electrophoretic deposition process. Appl Surf Sci. 2015;327:327–34. https://doi.org/10.1016/j.apsusc.2014.11.170.

Zhitomirsky D, Roether JA, Boccaccini AR, Zhitomirsky I. Electrophoretic deposition of bioactive glass/polimer composite coatings with and without HA nanoparticle inclusions for biomedical applications. J Mater Process Technol. 2009;209:1853–60. https://doi.org/10.1016/j.jmatprotec.2008.04.034.

Hadidi M, Bigham A, Saebnoori E, Hassanzadeh-Tabrizi SA, Rahmati S, Alizadeh ZM, Nasirian V, Rafienia M. Electrophoretic-deposited hydroxyapatite-copper nanocomposite as an antibacterial coating for biomedical applications. Surf Coat Technol. 2017;321:171–9. https://doi.org/10.1016/j.surfcoat.2017.04.055.

Ferrari B, Moreno R, Hernan L, Melero M, Morales J, Caballero A. EPD of thick films for their application in lithium batteries. J Eur Ceram. 2007;27:3823–7. https://doi.org/10.1016/j.jeurceramsoc.2007.02.051.

Du C, Pan N. Supercapacitors using carbon nanotubes films by electrophoretic deposition. J Power Sources. 2006;160:1487–94. https://doi.org/10.1016/j.jpowsour.2006.02.092.

Castro Y, Ferrari B, Moreno R, Duran A. Corrosion behavior of silica hybrid coatings produced from basic catalyzed particulate sols by dipping and EPD. Surf Coat Technol. 2005;191:228–35. https://doi.org/10.1016/j.surfcoat.2004.03.001.

Fiołek A, Zimowski S, Kopia A, Sitarz M, Moskalewicz T. Effect of low-friction composite polymer coatings fabricated by electrophoretic deposition and heat treatment on the Ti-6Al-4V titanium alloy’s tribological properties. Metall Mater Trans A Phys Metall Mater Sci. 2020;51:4786–98. https://doi.org/10.1007/s11661-020-05900-3.

Moskalewicz T, Warcaba M, Zimowski S, Łukaszczyk A. Improvement of the Ti-6Al-4V alloy’s tribological properties and electrochemical corrosion resistance by nanocomposite TiN/PEEK708 coatings. Metall Mater Trans A Phys Metall Mater Sci. 2019;50:5914–24. https://doi.org/10.1007/s11661-019-05484-7.

Besra L, Liu M. A review on fundamentals and applications of electrophoretic deposition (EPD). Prog Mater Sci. 2007;52:1–61. https://doi.org/10.1016/j.pmatsci.2006.07.001.

Yamashita K, Nagai M, Umegaki T. Fabrication of green films of single- and multicomponent ceramic composites by electrophoretic deposition technique. J Mater Sci. 1997;32:6661–4. https://doi.org/10.1023/A:1018608605080.

Luo D, Zhitomirsky I. Electrophoretic deposition of polyetheretherketone composites, containing huntite and alumina platelets. J Electrochem Soc. 2015;162:3057–62. https://doi.org/10.1149/2.0191511jes.

Kuśmierczyk F, Zimowski S, Łukaszczyk A, Kopia A, Cieniek Ł, Moskalewicz T. Development of microstructure and properties of multicomponent MoS2/HA/PEEK coatings on a titanium alloy via electrophoretic deposition and heat treatment. Metall Mater Trans A Phys Metall Mater Sci. 2021;52:3880–95. https://doi.org/10.1007/s11661-021-06350-1.

Kruk A, Zimowski S, Łukaszczyk A, Cieniek Ł, Moskalewicz T. The influence of heat treatment on the microstructure, surface topography and selected properties of PEEK coatings electrophoretically deposited on the Ti-6Al 4V alloy. Prog Org Coat. 2019;133:180–90. https://doi.org/10.1016/j.porgcoat.2019.04.049.

Vallar S, Houivet D, El Fallah J, Kervadec D, Haussonne JM. Oxide slurries stability and powders dispersion: optimization with zeta potential and rheological measurements. J Eur Ceram. 1999;19:1017–21. https://doi.org/10.1016/S0955-2219(98)00365-3.

Chung Y, Tsai C, Li C. Preparation and characterization of water-soluble chitosan produced by Maillard reaction. Fish Sci. 2006;72:1096–103. https://doi.org/10.1111/j.1444-2906.2006.01261.x.

Ferrari B, Moreno R. EPD kinetics: a review. J Eur Ceram. 2010;30:1069–78. https://doi.org/10.1016/j.jeurceramsoc.2009.08.022.

Ferrari B, Moreno R. The conductivity of aqueous Al2O3 slips for electrophoretic deposition. Mater Lett. 1996;28:353–5. https://doi.org/10.1016/0167-577X(96)00075-4.

Wu D, Zhu L, Li Y, Zhang X, Xu S, Yang G, Delair T. Chitosan-based colloidal polyelectrolyte complexes for drug delivery: a review. Carbohydr Polym. 2020;238: 116126. https://doi.org/10.1016/j.carbpol.2020.116126.

Kim S, Lee K, Lee K. Polyelectrolyte complex membranes based on two anionic polysaccharides composed of sodium alginate and carrageenan: the effect of annealing on the separation of methanol/water mixtures. J Appl Polym. 2006;102:5781–8. https://doi.org/10.1002/app.23903.

Hamlin RE, Dayton TL, Johnson LE, Johal MS. A QCM study of the immobilization of beta-galactosidase on polyelectrolyte surfaces: effect of the terminal polyion on enzymatic surface activity. Langmuir. 2007;23:4432–7. https://doi.org/10.1021/la063339t.

Ata MS, Liu Y, Zhitomirsky I. A review of new methods of surface chemical modification, dispersion and electrophoretic deposition of metal oxide particles. RSC Adv. 2014;4:22716–32. https://doi.org/10.1039/C4RA02218A.

Zhang D, Wang X, Peng X, Wang Q, Xiang Q. Kinetics of electrophoretic deposition of nano-Co3O4 coating. J Mater Sci Mater Electron. 2019;30:8967–73. https://doi.org/10.1007/s10854-019-01224-0.

Flores-Hernández CG, Cornejo-Villegas MDLA, Moreno-Martell A, Del Real A. Synthesis of a biodegradable polymer of poly (sodium alginate/ethyl acrylate). Polymers. 2021;13:504. https://doi.org/10.3390/polym13040504.

Zhang G, Yu H, Zhang C, Liao H, Coddet C. Temperature dependence of the tribological mechanisms of amorphous PEEK (polyetheretherketone) under dry sliding conditions. Acta Mater. 2008;56:2182–90. https://doi.org/10.1016/j.actamat.2008.01.018.

Acknowledgements

The authors appreciate the valuable contribution of M. Gajewska (ACMiN, AGH University of Krakow) for help with TEM investigation.

Funding

The study was supported by AGH-UST (project no. 16.16.110.663).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethics approval

The manuscript has been prepared by the contribution of all authors, it is the original authors’ work, it has not been published before. The paper is not currently being considered for publication elsewhere.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fiołek, A., Zimowski, S. & Moskalewicz, T. The effect of dispersing agents on the electrophoretic deposition, morphology and adhesion strength of multicomponent TiN/PTFE/PEEK coatings. Archiv.Civ.Mech.Eng 24, 48 (2024). https://doi.org/10.1007/s43452-024-00860-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-024-00860-6