Abstract

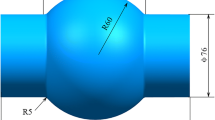

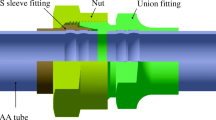

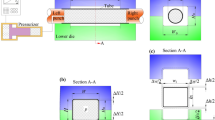

In the hydroforming process of a thin-walled tubular component with multiple local bulges, the bulge in the middle position is almost impossible to be formed with a conventional one-step hydroforming process because of the difficult axial feeding. To solve this problem, a novel method is proposed by preforming wrinkles using selective induction heating at different positions of tube blank to aggregate materials in advance for the subsequent hydroforming of tubular component with multiple local bulges. In this paper, the wrinkling behavior of 5052 aluminum alloy tube blank under different conditions and the deformation behavior of the wrinkled tube blank in subsequent hydroforming process of tubular component with three bulges are analyzed. It is shown that the existence of wrinkles is beneficial to increase the ultimate expansion ratio of the tube blank. Moreover, the instability behavior of multiple wrinkles on 5052 aluminum alloy tube blanks under different conditions was investigated by experiments. The process parameters for prefabricating two or three wrinkles, including temperature, spacing between wrinkles, and internal pressure, were determined through a detailed experimental investigation. Finally, the defects including splitting and undercut that occur in the hydroforming of tubular component with three bulges are analyzed, and the thin-walled tubular component with three bulges was hydroformed successfully using a wrinkled tube blank obtained under the process parameters of 250 °C, 4 mm, 5.5 MPa/350 °C, 10 mm, 2 MPa/400 °C, 6 mm, 1.33 MPa. These results provide insights for the manufacturing of tubular component with multiple local bulges from hard-to-form materials.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce the above findings cannot be shared at this time due to technical/time limitations.

References

Reddy PV, Reddy BV, Ramulu PJ. Evolution of hydroforming technologies and its applications—a review. J Adv Manuf Syst. 2021;19:737–80. https://doi.org/10.1142/S0219686720500341.

Stojanovic B, Bukvic M, Epler I. Application of aluminum and aluminum alloys in engineering. Appl Eng Lett. 2018;3:52–62. https://doi.org/10.18485/AELETTERS.2018.3.2.2.

Kumar D, Phanden RK, Thakur L. A review on environment friendly and lightweight magnesium-based metal matrix composites and alloys. Mater Today Proc. 2021;38:359–64. https://doi.org/10.1016/J.MATPR.2020.07.424.

Chu E, Xu Y. Hydroforming of aluminum extrusion tubes for automotive applications Part I: buckling, wrinkling and bursting analyses of aluminum tubes. Int J Mech Sci. 2004;46:263–83. https://doi.org/10.1016/J.IJMECSCI.2004.02.014.

Xia ZC. Failure analysis of tubular hydroforming. J Eng Mater Technol. 2001;123:423–9. https://doi.org/10.1115/1.1394966.

Strano M. Design and modelling of parts, process and tooling in tube hydroforming. Hydroforming Adv Manuf. 2008. https://doi.org/10.1533/9781845694418.1.121.

Yuan S, Wang X, Liu G, Wang ZR. Control and use of wrinkles in tube hydroforming. J Mater Process Technol. 2007;182:6–11. https://doi.org/10.1016/J.JMATPROTEC.2006.06.007.

Lang L, Yuan S, Wang X, Wang ZR, Fu Z, Danckert J, Nielsen KB. A study on numerical simulation of hydroforming of aluminum alloy tube. J Mater Process Technol. 2004;146:377–88. https://doi.org/10.1016/J.JMATPROTEC.2003.11.031.

Lang L, Li H, Yuan S, Danckert J, Nielsen KB. Investigation into the pre-forming’s effect during multi-stages of tube hydroforming of aluminum alloy tube by using useful wrinkles. J Mater Process Technol. 2009;209:2553–63. https://doi.org/10.1016/J.JMATPROTEC.2008.06.027.

Tang ZJ, Liu G, Bin He Z, Yuan SJ. Wrinkling behavior of magnesium alloy tube in warm hydroforming. Trans Nonferrous Met Soc China. 2010;20:1288–93. https://doi.org/10.1016/S1003-6326(09)60292-2.

Song WJ, Heo SC, Kim J, Kang BS. Investigation on preformed shape design to improve formability in tube hydroforming process using FEM. J Mater Process Technol. 2006;177:658–62. https://doi.org/10.1016/J.JMATPROTEC.2006.04.084.

Yuan SJ, Cui XL, Wang XS. Investigation into wrinkling behavior of thin-walled 5A02 aluminum alloy tubes under internal and external pressure. Int J Mech Sci. 2015;92:245–58. https://doi.org/10.1016/J.IJMECSCI.2014.12.017.

Kang BH, Lee MY, Shon SM, Moon YH. Forming various shapes of tubular bellows using a single-step hydroforming process. J Mater Process Technol. 2007;194:1–6. https://doi.org/10.1016/J.JMATPROTEC.2007.02.029.

Furushima T, Hung NQ, Manabe KI, Sasaki O. Development of semi-dieless metal bellows forming process. J Mater Process Technol. 2013;213:1406–11. https://doi.org/10.1016/J.JMATPROTEC.2013.03.002.

Zhang Z, Furushima T, Manabe K, Tada K, Sasaki O. Development of dieless metal bellows forming process with local heating technique. Proceed Instit Mech Eng Part B J Eng Manuf. 2014;229:664–9. https://doi.org/10.1177/0954405413519610.

Sedighi M, Shamsi M. A new approach in producing metal bellows by local arc heating: a parametric study. Int J Adv Manuf Technol. 2017;939:3211–9. https://doi.org/10.1007/S00170-017-0768-1.

Cui XL, Lin P, Chi CZ, Beneficial wrinkle prefabrication method for improving high-pressure forming limit in tube, n.d. https://d.wanfangdata.com.cn/patent/ChJQYXRlbnROZXdTMjAyMjAzMjMSE0NOMjAxOTEwMjE2MTg2Ljdfc3EaCGh6Z2x0M3Nl (accessed November 17, 2020).

Cui XL, Guo J, Wen SY, Wu XM, Lin P. Plastic wrinkling of thin-walled tubes under axial compression in non-uniform temperature field. Proc Inst Mech Eng Part C J Mech Eng Sci. 2022;237:406–19. https://doi.org/10.1177/09544062221121987.

Benham PP, Crawford RJ, Armstrong CG. Mechanics of engineering materials, 2nd editio, Harlow. Essex: Longman; 1996.

Acknowledgements

This investigation is financially supported by the National Natural Science Foundation of China (No. 51805357, U1937205), the Natural Science Foundation of Heilongjiang Province, China (No. LH2022E057), and the China Postdoctoral Science Foundation (No. 2020M670907). The authors wish to express their gratitude to the funding support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cui, XL., Guo, J., Zhao, Y. et al. Hydroforming process of thin-walled tubular components with multiple local bulges. Archiv.Civ.Mech.Eng 23, 169 (2023). https://doi.org/10.1007/s43452-023-00711-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-023-00711-w