Abstract

Renewable bamboo materials have broad application prospects in the fields of structural construction, insulation and acoustic management due to their multi-layer porous structure, attractive directional layout texture, ultra-fast growth rate, and excellent mechanical strength. However, the annual loss of bamboo material due to the microbial corrosion accounts for one-tenth of the total output. In this work, the hydrophobic associating hydrogel (HAH) with chitosan (CS) and zinc oxide (ZnO) has been in situ filled in the micro-nano-scale pores of natural bamboo materials to significantly enhance their anti-microbial fouling performance. It is difficult for the mildew and oxygen in the air to come into the bamboo materials due to the artificial hydrogel barrier layer. CS and ZnO nanomaterials further increase the anti-bacterial rate of bamboo composites to 100%. Based on the physical crosslinking between the polyacrylamide (PMA) of HAH hydrogel and natural bamboo fibers, CS and ZnO bacteriostatic media are not easy to be lost from the bamboo materials. The 100% anti-bacterial rate of the bamboo composite materials can be maintained for at least 56 days. Therefore, the bamboo composites have great application potential as building materials in the future.

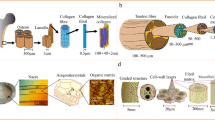

Graphical abstract

In-situ polymerization method was used to fill the micropores of bamboo with super-elastic hydrogel to enhance its anti-microbial fouling performance.

Similar content being viewed by others

References

Bilal M, Oyedele LO, Ajayi OO (2016) Big data architecture for construction waste analytics (CWA): a conceptual framework. J Build Eng 6:144–156

Fan X, Yin X (2018) Progress in research and development on matrix modification of continuous fiber-reinforced silicon carbide matrix composites. Adv Compos Hybrid Mater 1:685–695

Pei P, Xiong H, Cai J (2016) Enhanced the weatherability of bamboo fiber–based outdoor building decoration materials by rutile nano-TiO2. Constr Build Mater 114:307–316

Supomo H, Djatmiko EB, Zubaydi A (2018) Analysis of the adhesiveness and glue type selection in manufacturing of bamboo laminate composite for fishing boat building material. Appl Mech Mater 874:155–164

González D, Santos V, Parajó JC (2011) Manufacture of fibrous reinforcements for biocomposites and hemicellulosic oligomers from bamboo. Chem Eng J 167:278–287

Rao J, Bao L, Wang B (2018) Plasma surface modification and bonding enhancement for bamboo composites. Compos B Eng 138:157–167

Li MF, Sun SN, Xu F (2012) Formic acid based organosolv pulping of bamboo (Phyllostachys acuta): comparative characterization of the dissolved lignins with milled wood lignin. Chem Eng J 179:80–89

Kaur PJ (2018) Bamboo availability and utilization potential as a building material. Forest Res Eng Int J 2:240–242

Ghavami K (2005) Bamboo as reinforcement in structural concrete elements. Cement Concrete Comp 27:637–649

Yang L, Lou Z, Han X (2020) Fabrication of a novel magnetic reconstituted bamboo with mildew resistance properties. Mater Today Commun 23:101086–101092

Sun F, Zhou Y, Bao B (2011) Influence of solvent treatment on mould resistance of bamboo. BioResources 6:2091–2100

Deng J, Chen F, Wang G (2014) Hygrothermal aging properties, molding and abrasion resistance of bamboo keyboard. Eur J Wood Wood Prod 72:659–667

Wu Z, Huang D, Wei W (2018) Mesoporous aluminosilicate improves mildew resistance of bamboo scrimber with Cu B P anti-mildew agents. J Clean Prod 209:273–282

Zhang X, Zhang ZF, Huang K (2013) Study on the kinetics of immersion of photocatalyst in bamboo. Appl Mech Mater 271–272:218–221

Xie J, Hse CY, Shupe TF (2016) Influence of solvent type on microwave-assisted liquefaction of bamboo. Eur J Wood Wood Prod 74:249–254

Rana B, Awasthi P, Kumbhar BK (2012) Optimization of processing conditions for cyanide content reduction in fresh bamboo shoot during NaCl treatment by response surface methodology. J Food Sci Tech 49:103–109

Legesse AA, Gebremeskel SA, Paramasivam V (2021) Development and characterization of bamboo-sesame stalk hybrid urea-formaldehyde matrix composite for particleboard application. Mater Today Proc 46:7351–7358

Razak W, Samsi HW, Mahmud S (2004) Strength and durability of bamboo treated through an oil-curing process. J Biol Sci 4:658–663

Gao J, Lin H, Wen A (2020) Zinc complex derived from ZnCl2-urea ionic liquid for improving mildew property of bamboo. Coatings 10:1233–1232

Zhang H, Zhong J, Wang N (2021) Dyed bamboo composite materials with excellent anti-microbial corrosion. Adv Compos Hybrid Mater 4:294–305

Sun F, Bao B, Ma L (2012) Mould-resistance of bamboo treated with the compound of chitosan-copper complex and organic fungicides. J Wood Sci 58:51–56

Harsh NSK, Singh YP, Gupta HK (2005) A new culm rot disease of bamboo in India and its management. J Bamboo Rattan 4:387–398

Han J, Luo D (2012) Valuation on mildew-proof results of ACQ-B to bamboo. Adv Mater Res 580:517–520

Pasquet J, Chevalier Y, Couval E (2014) Antimicrobial activity of zinc oxide particles on five microorganisms of the challenge tests related to their physicochemical properties. Int J Pharm 460:92–100

Mei XJ, Wang ZW, Zheng X (2014) Soluble microbial products in membrane bioreactors in the presence of ZnO nanoparticles. J Membr Sci 451:169–176

Liu L, Li X, Ren X (2020) Flexible strain sensors with rapid self-healing by multiple hydrogen bonds. Polymer 202:122657–122665

Yuan N, Xu L, Wang H (2016) Dual physically cross-linked double network hydrogels with high mechanical strength, fatigue resistance, notch-insensitivity, and self-healing properties. Acs Appl Mater Interfaces 8:34034–34044

Xu K, An H, Lu C (2013) Facile fabrication method of hydrophobic-associating cross-linking hydrogel with outstanding mechanical performance and self-healing property in the absence of surfactants. Polymer 21:5665–5672

Zhang X, Peng Y, Shi L (2020) Highly efficient solar evaporator based on a hydrophobic association hydrogel. ACS Sustainable Chem Eng 8:18114–18125

Zhang H, Liu Z, Mai J (2021) Super-elastic smart phase change material (SPCM) for thermal energy storage. Chem Eng J 411:128482–128489

Lalehgani Z, Ramazani SAA, Tamsilian Y (2019) Inverse emulsion polymerization of triple monomers of acrylamide, maleic anhydride, and styrene to achieve highly hydrophilic–hydrophobic modified polyacrylamide. J Appl Polym Sci 136:47753–47761

Wu X, Shao G, Shen X (2017) Evolution of the novel C/SiO2/SiC ternary aerogel with high specific surface area and improved oxidation resistance. Chem Eng J 330:1022–1034

Wu X, Shao G, Cui S (2016) Synthesis of a novel Al2O3–SiO2 composite aerogel with high specific surface area at elevated temperatures using inexpensive inorganic salt of aluminum. Ceram Int 42:874–882

Acknowledgements

H.Q. and N. designed the experiment and wrote the paper. J.P., H.J., Z.J., R.J. X., J. and Q.J. helped conduct the experimental work. X.M. and N. helped conduct the experimental work and analyze the results. H.Q. and X.M. directed this work and revised the manuscript.

Funding

This work was supported by the Hainan Science and Technology Major Project (ZDKJ2019013), National Natural Science Foundation of China (No. 51775152, 61761016, 22065012 and U1967213), National Key R&D Program of China (2018YFE0103500), Start-up Research Foundation of Hainan University (KYQD(ZR)1911), and Project Supported by Open Project of State Key Laboratory of Marine Resource Utilization in South China Sea (Hainan University) (No. MRUKF2021025).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mai, X., Mai, J., Liu, H. et al. Advanced bamboo composite materials with high-efficiency and long-term anti-microbial fouling performance. Adv Compos Hybrid Mater 5, 864–871 (2022). https://doi.org/10.1007/s42114-021-00380-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00380-4