Abstract

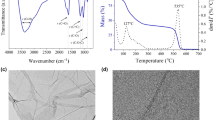

Graphene has been proved to have an obvious superiority in suppression of the wear of polymers. However, the wide industrial application was suppressed by the bad graphene dispersion and complex preparation procedure. In this work, we employed carbon spheres coated with dispersed graphene (graphene spheres, g-AM) as filler to prepare the epoxy composites with direct mixing and curing. Comparing with neat epoxy and composites filled with calcined carbon spheres (CM, without graphene), the thermal and tribological properties of g-AM/EP composites were improved when the g-AM content was low. When chemical functionalization by grafting epoxy chain on the graphene (E–g-AM) was conducted, the total performance, especially the wear resistance, was remarkably improved even at high graphene content. The wear rate of E–g-AM/EP composites was reduced by 95% at 20 wt.% E–g-AM, compared to pure cured epoxy resin. This superior wear resistance was related to the synergistic effect of carbon spheres and graphene. Carbon spheres improved shore hardness and flexural strength, thus reducing the wear rate. The graphene had the high dispersion and good interface adhesion with epoxy, leading to the excellent lubricating effect and the improved mechanical and thermal performance of the composites.

Graphical abstract

Graphene spheres with high dispersion state were firstly used as fillers of epoxy and made the composite excellent wear resistance.

Similar content being viewed by others

References

Rafiee R (2016) On the mechanical performance of glass-fiber-reinforced thermosetting-resin pipes: a review. Compos Struct 143:151–164. https://doi.org/10.1016/j.compstruct.2016.02.037

Tang LC, Wan YJ, Yan D, Pei YB, Zhao L, Li YB, Wu LB, Jiang JX, Lai GQ (2013) The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon 60:16–27. https://doi.org/10.1016/j.carbon.2013.03.050

Ahmad S, Gupta AP, Sharmin E, Alam M, Pandey SK (2005) Synthesis, characterization and development of high performance siloxane-modified epoxy paints. Prog Org Coat 54:248–255. https://doi.org/10.1016/j.porgcoat.2005.06.013

Xavier JR (2020) Investigation on the anticorrosion, adhesion and mechanical performance of epoxy nanocomposite coatings containing epoxy-silane treated nano-MoO3 on mild steel. J Adhes Sci Technol 34:115–134. https://doi.org/10.1080/01694243.2019.1661658

Bustero I, Gaztelumendi I, Obieta I, Mendizabal MA, Zurutuza A, Ortega A, Alonso B (2020) Free-standing graphene films embedded in epoxy resin with enhanced thermal properties. Adv Compos Hybrid Mater 3(1):31–40. https://doi.org/10.1007/s42114-020-00136-6

Zhang JX, Liang YX, Wang XJ, Zhou HJ, Li SY, Zhang J, Feng YN, Lu N, Wang Q, Guo ZH (2018) Strengthened epoxy resin with hyperbranched polyamine-ester anchored graphene oxide via novel phase transfer approach. Adv Compos Hybrid Mater 1(2):300–309. https://doi.org/10.1007/s42114-017-0007-0

He Y, Wu D, Zhou M, Liu H, Zhang L, Chen Q, Yao B, Yao D, Jiang D, Liu C, Guo Z (2020) Effect of MoO3/carbon nanotubes on friction and wear performance of glass fabric-reinforced epoxy composites under dry sliding. Appl Surf Sci 506:144946. https://doi.org/10.1016/j.apsusc.2019.144946

Österle W, Dmitriev AI, Gradt T, Häusler I, Hammouri B, Morales Guzman PI, Wetzel B, Yigit D, Zhang G (2015) Exploring the beneficial role of tribofilms formed from an epoxy-based hybrid nanocomposite. Tribol Int 88:126–134. https://doi.org/10.1016/j.triboint.2015.03.006

EL-Tayeb NSM, Liew KW (2009) On the dry and wet sliding performance of potentially new frictional brake pad materials for automotive industry. Wear 266:275–287. https://doi.org/10.1016/j.wear.2008.07.003

Shen XJ, Pei XQ, Fu SY, Friedrich K (2013) Significantly modified tribological performance of epoxy nanocomposites at very low graphene oxide content. Polymer 54:1234–1242. https://doi.org/10.1016/j.polymer.2012.12.064

Shen XJ, Pei XQ, Liu Y, Fu SY (2014) Tribological performance of carbon nanotube–graphene oxide hybrid/ epoxy composites. Compos B Eng 57:120–125. https://doi.org/10.1016/j.compositesb.2013.09.050

Lahiri D, Hec F, Thiesse M, Durygin A, Zhang C, Agarwal A (2014) Nanotribological behavior of graphene nanoplatelet reinforced ultra high molecular weight polyethylene composites. Tribol Int 70:165–169. https://doi.org/10.1016/j.triboint.2013.10.012

Wang H, Xie GY, Zhu ZG, Ying Z, Zeng Y (2014) Enhanced tribological performance of the multi-layer graphene filledpoly(vinyl chloride) composites. Compos Part A Appl Sci Manuf 67:268–273. https://doi.org/10.1016/j.compositesa.2014.09.011

Zhao F, Zhang L, Li G, Guo Y, Qi H, Zhang G (2018) Significantly enhancing tribological performance of epoxy by filling with ionic liquid functionalized graphene oxide. Carbon 136:309–319. https://doi.org/10.1016/j.carbon.2018.05.002

Tai ZX, Chen YF, An YF, Yan XB, Xue QJ (2012) Tribological behavior of UHMWPE reinforced with graphene oxide nanosheets. Tribol Lett 46:55–63. https://doi.org/10.1007/s11249-012-9919-6

Wang TC, Xiong DS, Zhou T (2010) Preparation and wear behavior of carbon/epoxy resin composites with an interpenetrating network structure derived from natural sponge. Carbon 48:2435–2441. https://doi.org/10.1016/j.carbon.2010.03.011

Wetzela B, Hauperta F, Zhang MQ (2003) Epoxy nanocomposites with high mechanical and tribological performance. Compos Sci Technol 63:2055–2067. https://doi.org/10.1016/S0266-3538(03)00115-5

Mo Y, Yang ML, Lu ZX, Huang FC (2013) Preparation and tribological performance of chemically-modified reduced graphene oxide/polyacrylonitrile composites. Compos Part A Appl Sci Manuf 54:153–158. https://doi.org/10.1016/j.compositesa.2013.07.014

Kandanur SS, Rafiee MA, Yavari F, Schrameyer M, Yu ZZ, Blanchet TA, Koratkar N (2012) Suppression of wear in graphene polymer composites. Carbon 50:3178–3183. https://doi.org/10.1016/j.carbon.2011.10.038

Chen C, Qiu SH, Cui MJ, Qin SL, Yan GP, Zhao HC, Wang LP, Xue QJ (2017) Achieving high performance corrosion and wear resistant epoxy coatings via incorporation of noncovalent functionalized graphene. Carbon 114:356–366. https://doi.org/10.1016/j.carbon.2016.12.044

Min CY, Nie P, Song HJ, Zhang ZZ, Zhao KL (2014) Study of tribological properties of polyimide/graphene oxide nanocomposite films under seawater-lubricated condition. Tribol Int 80:131–140. https://doi.org/10.1016/j.triboint.2014.06.022

Yi M, Shen ZG (2015) A review on mechanical exfoliation for the scalable production of graphene. J Mater Chem A 3:11700–11715. https://doi.org/10.1039/C5TA00252D

Nicolosi V, Chhowalla M, Kanatzidis MG, Strano MS, Coleman JN (2013) Liquid exfoliation of layered materials. Science 340:1226419. https://doi.org/10.1126/science.1226419

Park SJ, Ruoff RS (2009) Chemical methods for the production of graphenes. Nat Nanotechnol 4:217–224. https://doi.org/10.1038/nnano.2009.58

Allen MJ, Tung VC, Kaner RB (2010) Honeycomb carbon: a review of graphene. Chem Rev 110:132–145. https://doi.org/10.1021/cr900070d

Viculis LM, Mack JJ, Kaner RB (2003) A chemical route to carbon nanoscrolls. Science 299:1361. https://doi.org/10.1126/science.1078842

Reina A, Jia XT, Ho J, Nezich D, Son H, Bulovic V, Dresselhaus SM, Kong J (2009) Large area, few-layer graphene films on arbitrary substrates by chemical vapor deposition. Nano Lett 9:30–35. https://doi.org/10.1021/nl801827v

Ryu J, Kim Y, Won D, Kim N, Park JS, Lee EK, Cho D, Cho SP, Kim SJ, Ryu GH, Shin HAS, Lee Z, Hong BH, Cho S (2014) Fast synthesis of high-performance graphene films by hydrogen-free rapid thermal chemical vapor deposition. ACS Nano 8:950–956. https://doi.org/10.1021/nn405754d

Kuila T, Bose S, Hong CE, Uddin ME, Khanra P, Kim NH, Lee JH (2011) Preparation of functionalized graphene/linear low density polyethylene composites by a solution mixing method. Carbon 49:1033–1037. https://doi.org/10.1016/j.carbon.2010.10.031

Potts JR, Lee SH, Alam TM, An J, Stoller MD, Piner RD, Ruoff RS (2011) Thermomechanical properties of chemically modified graphene/poly(methyl methacrylate) composites made by in situ polymerization. Carbon 49:2615–2623. https://doi.org/10.1016/j.carbon.2011.02.023

Wang JY, Yang SY, Huang YL, Tien HW, Chin WK, Ma CCM (2011) Preparation and properties of graphene oxide/polyimide composite films with low dielectric constant and ultrahigh strength via in situ polymerization. J Mater Chem 21:13569–13575. https://doi.org/10.1039/C1JM11766A

Xu X, Yang C, Yang J, Huang T, Zhang N, Wang Y, Zhou Z (2017) Excellent dielectric properties of poly(vinylidene fluoride) composites based on partially reduced graphene oxide. Compos B Eng 109:91–100. https://doi.org/10.1016/j.compositesb.2016.10.056

Wang P, Chong H, Zhang J, Yang Y, Lu H (2018) Ultralow electrical percolation in melt-compounded polymer composites based on chemically expanded graphite. Compos Sci Technol 158:147–155. https://doi.org/10.1016/j.compscitech.2018.01.022

Zaheer U, Khurram AA, Subhani T (2018) A treatise on multiscale glass fiber epoxy matrix composites containing graphene nanoplatelets. Adv Compos Hybrid Mater 1(4):705–721. https://doi.org/10.1007/s42114-018-0057-y

Xia H, Wang K, Yang S, Shi Z, Wang H, Wang J (2016) Formation of graphene flowers during high temperature activation of mesocarbon microbeads with KOH. Microporous Mesoporous Mater 234:384–391. https://doi.org/10.1016/j.micromeso.2016.07.046

Shen B, Zhai W, Tao M, Lu D, Zheng W (2013) Chemical functionalization of graphene oxide toward the tailoring of the interface in polymer composites. Compos Sci Technol 77:87–94. https://doi.org/10.1016/j.compscitech.2013.01.014

Sadagopan K, Ratna D, Samui AB (2003) Synthesis and characterization of liquid-crystalline epoxy and its blend with conventional epoxy. J Polym Sci Part A: Polym Chem 41:3375–3383. https://doi.org/10.1002/pola.10923

Tang L, Zhang JL, Gu JW (2021) Random copolymer membrane coated PBO fibers with significantly improved interfacial adhesion for PBO fibers/cyanate ester composites. Chinese J Aeronaut 34(2):659–668. https://doi.org/10.1016/j.cja.2020.03.007

Xia HY, Wang JP, Shi ZQ, Liu GW, Qiao GJ (2012) Sliding wear behavior of mesocarbon microbeads based carbon materials. Wear 274–275:260–266. https://doi.org/10.1016/j.wear.2011.09.004

Xia HY, Qiao GJ, Zhou SL, Wang JP (2013) Reciprocating friction and wear behavior of reaction–formed SiC ceramic against bearing steel ball. Wear 303:276–285. https://doi.org/10.1016/j.wear.2013.03.038

Dhieb H, Buijnsters JG, Eddoumy F, Celis JP (2011) Surface damage of unidirectional carbon fiber reinforced epoxy composites under reciprocating sliding in ambient air. Compos Sci Technol 71:1769–1776. https://doi.org/10.1016/j.compscitech.2011.08.012

Acknowledgements

The authors are grateful to the Shaanxi Innovation Capacity Support Program (2018TD-031), Natural Science Foundation of Shaanxi (2018JQ5008), Fundamental Research Funds for the Central University (XJJ2018003), and Science and Technology project from Headquarters of State Grid Co., LTD (SGAH0000KJJS1900437).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xia, H., Li, J., Wang, K. et al. Superior wear resistance of epoxy composite with highly dispersed graphene spheres. Adv Compos Hybrid Mater 5, 173–183 (2022). https://doi.org/10.1007/s42114-021-00259-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00259-4