Abstract

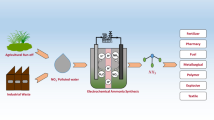

Process intensification research is concentrated on the use of the continuous flow microreactor over the conventional batch reactors due to the various advantages that bring this latter in terms of efficient micromixing and enhanced heat and mass transfer in small residence time. The continuous flow process has been successfully developed for many common reactions in the pharmaceutical and chemical industries. This paper explores the catalytic performance of Pd nanoparticles (NPs) in a continuous flow mode and studies different microreactors configuration, and their applications on the benchmark reaction model of 4-nitrophenol reduction in aqueous media by using sodium borohydride as a reducer. A PTFE Spiral Capillary Microreactor (SCM) was designed and compared to a Continuous Vessel Microreactor (CVM) for the reduction of 4-Nip into 4-Amp. Multiple equations were obtained from different microreactor configurations that can be used for the calculation of theoretical mean conversion and 4-nitrophenol concentration at the outlet of the microreactor. The kinetics studies of this reaction model already determined in batch reactor were confirmed by using pseudo-first order in continuous flow microreactor. The real microreactor (SCM) is acting as a plug flow reactor (PFR). The engineering aspects such as reaction conditions and microreactor model are discussed. This work studies the kinetics of the 4-Nip reduction for the first time with nanoparticles non supported in continuous flow. This work showed that the kinetic study of the reaction can be carried out successfully in SCM and advantageously in particular for short reaction times.

Similar content being viewed by others

Data availability

Not applicable

Code availability

Not applicable

References

Antonels NC, Meijboom R (2013) Preparation of well-de fined dendrimer encapsulated ruthenium nanoparticles and their evaluation in the reduction of 4 - nitrophenol according to the Langmuir − Hinshelwood approach. Langmuir 29:13433–13442

Chen J, Song M, Li Y, Zhang Y, Taya K, Li CM (2016) The effect of phytosterol protects rats against 4-nitrophenol-induced liver damage. Environ Toxicol Pharmacol 41:266–271

Narayanan KB, Sakthivel N (2011) Synthesis and characterization of nano-gold composite using Cylindrocladium floridanum and its heterogeneous catalysis in the degradation of 4-nitrophenol. J Hazard Mater 189(1–2):519–525

Behnajady MA, Amirmohammadi-Sorkhabi S, Modirshahla N, Shokri M (2011) Investigation of the efficiency of a tubular continuous-flow photoreactor with supported titanium dioxide nanoparticles in the removal of 4-nitrophenol: Operational parameters, kinetics analysis and mineralization studies. Water Sci Technol 64(1):56–62

Liu Y, Zheng Y, Du B, Nasaruddin RR, Chen T, Xie J (2017) Golden carbon nanotube membrane for continuous flow catalysis. Ind Eng Chem Res 56(11):2999–3007

Bolisetty S, Arcari M, Adamcik J, Mezzenga R (2015) Hybrid amyloid membranes for continuous flow catalysis. Langmuir 31(51):13867–13873

Astruc D (2007) Nanoparticles and catalysis. Wiley-VCH Verlag GmbH & Co. KGaA

Ferrando R, Jellinek J, Johnston RL (2008) Nanoalloys: from theory to applications of alloy clusters and nanoparticles. Chem Rev 108(3):845–910

Campbell CT, Parker SC, Starr DE (2002) The effect of size-dependent nanoparticle energetics on catalyst sintering. Science (80-) 298(5594):811–814

Zahmakıran M, Özkar S (2011) Metal nanoparticles in liquid phase catalysis; from recent advances to future goals. Nanoscale 3(9):3462

IbenAyad A, Belda Marín C, Colaco E, Lefevre C, Méthivier C, OuldDris A, Landoulsi J, Guénin E (2019) ‘water soluble’ palladium nanoparticle engineering for C-C coupling, reduction and cyclization catalysis. Green Chem 21(24):6646–6657

Hervés P, Pérez-Lorenzo M, Liz-Marzán LM, Dzubiella J, Lu Y, Ballauff M (2012) Catalysis by metallic nanoparticles in aqueous solution: Model reactions. Chem Soc Rev 41(17):5577–5587

Pradhan N, Pal A, Pal T (2002) Silver nanoparticle catalyzed reduction of aromatic nitro compounds. Colloids Surf A Physicochem Eng Asp 196(2–3):247–257

Wunder S, Lu Y, Albrecht M (2011) Catalytic activity of facetted gold nanoparticles studied by a model reaction: Evidence for substrate-induced surface restructuring. ACS Catal 1:908–916

Wunder S, Polzer F, Lu Y, Mei Y, Ballauff M (2010) Kinetic analysis of catalytic reduction of 4-nitrophenol by metallic nanoparticles immobilized in spherical polyelectrolyte brushes. J Phys Chem C 114(19):8814–8820

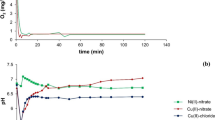

IbenAyad A, Luart D, OuldDris A, Guénin E (2020) Kinetic analysis of 4-nitrophenol reduction by ‘water-soluble’ palladium nanoparticles. Nanomaterials 10(6):1–16

Chang G, Luo Y, Lu W, Qin X, Asiri AM, Al-Youbi AO, Sun X (2012) Ag nanoparticles decorated polyaniline nanofibers: Synthesis, characterization, and applications toward catalytic reduction of 4-nitrophenol and electrochemical detection of H 2O 2 and glucose. Catal Sci Technol 2(4):800–806

Kohantorabi M, Gholami MR (2017) Kinetic analysis of the reduction of 4-nitrophenol catalyzed by CeO 2 nanorods-supported CuNi nanoparticles. Ind Eng Chem Res 56(5):1159–1167

Harish S, Mathiyarasu J, Phani KLN, Yegnaraman V (2009) Synthesis of conducting polymer supported Pd nanoparticles in aqueous medium and catalytic activity towards 4-nitrophenol reduction. Catal Lett 128(1–2):197–202

Koga H, Namba N, Takahashi T, Nogi M, Nishina Y (2017) Renewable wood pulp paper reactor with hierarchical micro/nanopores for continuous-flow nanocatalysis. Chemsuschem 10(12):2560–2565

Xie ZT, Asoh TA, Uetake Y, Sakurai H, Uyama H (2020) Dual roles of cellulose monolith in the continuous-flow generation and support of gold nanoparticles for green catalyst. Carbohydr Polym 247(July):116723

Yu Y, Xiao W, Zhou T, Zhang P, Yan C, Zheng Z (2017) Monolithic hierarchical gold sponges for efficient and stable catalysis in a continuous-flow microreactor. Mater Chem Front 1(3):482–486

Yue J (2018) Multiphase flow processing in microreactors combined with heterogeneous catalysis for efficient and sustainable chemical synthesis. Catal Today 308:3–19

Baumann M, Moody TS, Smyth M, Wharry S (2020) A perspective on continuous flow chemistry in the pharmaceutical industry. Org Process Res Dev 24(10):1802–1813

Wiles C, Watts P (2012) Continuous flow reactors: a perspective. Green Chem 14(1):38–54

Chinnery PF, Database C, Rev S, Jamison TF, Jensen KF, Monbaliu JM (2016) On-demand continuous-flow production of pharmaceuticals in a compact, reconfigurable system. Science (80-) 352(6281):61–68

Noêl T, Buchwald SL (2011) Cross-coupling in flow. Chem Soc Rev 40(10):5010–5029

Hommes A, Heeres HJ, Yue J (2019) Catalytic transformation of biomass derivatives to value-added chemicals and fuels in continuous flow microreactors. ChemCatChem 11(19):4671–4708

Fischer J, Liebner C, Hieronymus H, Klemm E (2009) Maximum safe diameters of microcapillaries for a stoichiometric ethene/oxygen mixture. Chem Eng Sci 64(12):2951–2956

Jensen KF (2017) Flow chemistry – Microreaction technology comes of age. AIChE J 63(3):858–869

Haswell SJ, Watts P (2003) Green chemistry: synthesis in micro reactors. Green Chem 5(2):240–249

Inoue T, Schmidt MA, Jensen KF (2007) Microfabricated multiphase reactors for the direct synthesis of hydrogen peroxide from hydrogen and oxygen. Ind Eng Chem Res 46(4):1153–1160

Jensen KF (2001) Microreaction engineering - is small better? 56: 293–303

Aroh KC, Jensen KF (2018) Efficient kinetic experiments in continuous flow microreactors. React Chem Eng 3(1):94–101

McMullen JP, Jensen KF (2010) Integrated microreactors for reaction automation: New approaches to reaction development. Annu Rev Anal Chem 3(1):19–42

Yue J, Schouten JC, Alexander Nijhuis T (2012) Integration of microreactors with spectroscopic detection for online reaction monitoring and catalyst characterization. Ind Eng Chem Res 51(45):14583–14609

Keybl J, Jensen KF (2011) Microreactor system for high-pressure continuous flow homogeneous catalysis measurements. Ind Eng Chem Res 50(19):11013–11022

Susanti, Winkelman JGM, Schuur B, Heeres HJ, Yue J (2016) Lactic acid extraction and mass transfer characteristics in slug flow capillary microreactors. Ind Eng Chem Res 55(16):4691–4702

Geyer K, Codée JDC, Seeberger PH (2006) Microreactors as tools for synthetic chemists - The chemists’ round-bottomed flask of the 21st century? Chem A Eur J 12(33):8434–8442

Anastas P, Eghbali N (2010) Green chemistry: principles and practice. Chem Soc Rev 39(1):301–312

Gu S et al (2014) Kinetic analysis of the catalytic reduction of 4-nitrophenol by metallic nanoparticles. J Phys Chem C 118(32):18618–18625

Ning X, Wei F, Fu H, Qu X, Xu Z, Zheng S (2018) Enhanced catalytic reduction of 4-nitrophenol over titania nanotube supported gold nanoparticles by weak ultraviolet light irradiation: role of gold surface charge. Appl Surf Sci 445:535–541

Tomei MC, Annesini MC, Bussoletti S (2004) 4-Nitrophenol biodegradation in a sequencing batch reactor: Kinetic study and effect of filling time. Water Res 38(2):375–384

Kästner C, Thünemann AF (2016) Catalytic reduction of 4-nitrophenol using silver nanoparticles with adjustable activity. Langmuir 32(29):7383–7391

Fogler HS (2010) Essentials of Chemical Reaction Engineering: Essenti Chemica Reactio Engi, Pearson Ed

Fogler HS (2016) Elements of chemical reaction engineering, 5th edn. Prentice Hall, Philadelphia

Author information

Authors and Affiliations

Contributions

A.I. conceived and designed the experiments; A.I. performed the experiments and analyzed the data; A.I., A.O., and E.G., provided the concept of this research and managed all the experimental and writing process as the corresponding authors; all authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Additional declarations for articles in life science journals that report the results of studies involving humans and/or animals

Not applicable

Conflicts of interest/Competing interests

The authors declare no conflict of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

- Kinetics study of nitro-phenol reduction in the presence of Pd nanoparticles can be performed successfully in a PTFE Spiral Capillary Microreactor.

- Since the reduction of nitrophenol is a pseudo first order reaction, this work has confirmed that a reactor close to the plug reactor (PR) is giving a higher conversion than a reactor that is close to a continuously stirred tank reactor (CSTR)

- The experimental results with PTFE Spiral Capillary Microreactor are close to those of plug reactor model in comparison to those of the laminar flow reactor model even if the flow is taking place in the laminar flow regime.

Rights and permissions

About this article

Cite this article

Iben Ayad, A., Guenin, E. & Ould Dris, A. Continuous flow reduction of 4-nitrophenol by “water soluble” palladium nanoparticles: from batch to continuous flow system. J Flow Chem 12, 101–111 (2022). https://doi.org/10.1007/s41981-021-00194-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41981-021-00194-x