Abstract

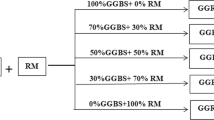

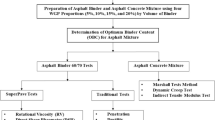

The present study aims to evaluate the possibility of perpetual pavement design with stabilized black cotton soil and polymer-modified bitumen for the major highways in India. Ground granulated blast slag (GGBS) was proposed as a potential material for use in pavements on weak subgrades, with proportions of 10%, 20%, 30%, and 40% added to the black cotton soil. Modified proctor compaction and California bearing ratio tests were conducted to determine the engineering properties of the soil and GGBS mixture. The study also aimed to design a high modulus bituminous concrete mixture for perpetual pavements using a combination of styrene–butadiene–styrene (SBS) polymer and viscosity grade 30 (VG 30) bitumen, with SBS added to the bitumen in amounts ranging from 1 to 4% by total weight. The physical and mechanical properties of both SBS-modified bitumen and neat bitumen were determined. Based on these results, 16 combinations of perpetual pavements were designed using the mechanistic–empirical methodology and according to Indian Road Congress (IRC 37: 2018) guidelines, with the aid of the IITPAVE software. These pavements included both treated and non-treated subgrades, as well as modified and unmodified mixes. The study found that the use of a sturdy foundation, treated subgrade, and high stiffness base materials is crucial in reducing the significant cost associated with using bitumen in a developing and oil-importing country like India. The designed pavements were also compared in terms of cost assessment and carbon dioxide emissions to determine the best option among the proposed combinations.

Similar content being viewed by others

Data availability

The database generated, collected, and/or analyzed during the current study is available from the corresponding author upon reasonable request.

References

IRC 37 (2018) Guidelines for design of flexible pavement, fourth revision, Indian Road Congress, New Delhi, 2018

MoRT&H (2013) Ministry of road transport and highways. Specifications for road and bridge works (5th revision). New Delhi, India

Sidess A, Uzan J (2009) A design method of perpetual flexible pavement in Israel. Int J Pavem Eng 10(4):241–249. https://doi.org/10.1080/10298430701830225

Newcomb DE, Buncher M, Huddleston IJ (2001) Concepts of perpetual pavements. Transportation research circular no. 503, 4–11. Transportation Research Board, Washington, DC

Wild S, Kinuthia JM, Jones GI, Higgins DD (1998) Effects of partial substitution of lime with ground granulated blast furnace slag (GGBS) on the strength properties of lime stabilised sulphate bearing clay soils. Eng Geol 51:37–53. https://doi.org/10.1016/s0013-7952(98)00039-8

Noolu V, Mudavath H, Pillai RJ, Yantrapalli SK (2019) Permanent deformation behaviour of black cotton soil treated with calcium carbide residue. Constr Build Mater 223:441–449. https://doi.org/10.1016/j.conbuildmat.2019.07.010

Sybilski D (1996) Zero-shear viscosity of bituminous binder and its relation to bituminous mixture. Transport Res Rec 1535(1):15–21. https://doi.org/10.1177/0361198196153500103

Bahia HU, Hanson DI, Zeng M, Zhai H, Khatri MA, Anderson RM (2001) Characterization of modified asphalt binders in superpave mix design. NCHRP rep. no. 459. National Academy Press, Washington, DC

Shenoy A (2008) Non recovered compliance from dynamic oscillatory testvis-à-vision recovered compliance from multiple stress creep recovery test in the dynamic shear rheometer. Int J Pavem Eng 9(5):329–341. https://doi.org/10.1080/10298430701635095

D’Angelo JA (2009) The relationship of the MSCR test to rutting. Road Mater Pavem Des 10:61–80. https://doi.org/10.3166/rmpd.10hs.61-80

Morea F, Agnusdei JO, Zerbino R (2010) The use of asphalt low shear viscosity to predict permanent deformation performance of asphalt concrete. Mater Struct 44(7):1241–1248. https://doi.org/10.1617/s11527-010-9696-3

Dongré R, D’Angelo J, Reinke G, Shenoy A (2004) New criterion for superpave high-temperature binder specification. Transp Res Rec 1875(1):22–32

Morea F, Agnusdei JO, Zerbino R (2011) The use of asphalt low shear viscosity to predict permanent deformation performance of asphalt concrete. Mater Struct 44(7):1241–1248

Kulkarni S, Ranadive M (2021) Effect of change in the resilient modulus of bituminous mix on the design of flexible perpetual pavement. Techno-Societal 2020. Springer, Cham, pp 829–838. https://doi.org/10.1007/978-3-030-69921-5_83

Cement Manufacturers’ Association, Grameen Sampark (2006) Cement concrete roads v/s bituminous roads—a cost analysis, Vol II, National Rural Road Development Agency, New Delhi, 2006

Biswas WK (2014) Carbon footprint and embodied energy consumption assessment of building construction works in Western Australia. Int J Sustain Built Environ 3(2):179–186

Praseeda KI, Reddy BV, Mani M (2015) Embodied energy assessment of building materials in India using process and input–output analysis. Energy Build 86:677–686

Omar WMSW (2018) A hybrid life cycle assessment of embodied energy and carbon emissions from conventional and industrialised building systems in Malaysia. Energy Build 167:253–268

Kumanayake R, Luo H, Paulusz N (2018) Assessment of material related embodied carbon of an office building in Sri Lanka. Energy Build 166:250–257

Gibson S, Strachan P (2011) Reducing the embodied carbon content of asphalt. University of Strathclyde, Glasgow

Sreedhar S, Jichkar P, Biligiri KP (2016) Investigation of carbon footprints of highway construction materials in India. Transport Res Procedia 17:291–300

Maini S, Thautam V (2009) Embodied energy of various materials and technologies, Auroville Earth Institute, Tamil Nadu, India. 2009

Hammond G, Jones C (2008) Inventory of carbon and energy: ICE. Bath: Sustainable Energy Research Team, Department of Mechanical Engineering, University of Bath, 2008

Gong X, Nie Z, Wang Z, Cui S, Gao F, Zuo T (2012) Life cycle energy consumption and carbon dioxide emission of residential building designs in Beijing: a comparative study. J Ind Ecol 16(4):576–587. https://doi.org/10.1111/j.1530-9290.2011.00415.x

IRC SP:89 (2010) Guidelines for soil and granular material stabilization using cement lime and fly ash, Indian Road Congress, New Delhi, 2010

IRC SP: 53 (2010) Guidelines on use of modified bitumen in road construction, second revision, Indian Road Congress, New Delhi, 2010

Author information

Authors and Affiliations

Contributions

The authors confirm responsibility for the following: study conception, data collection, analysis and interpretation of results, and manuscript preparation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kulkarni, S., Ranadive, M. Optimizing perpetual pavement design in India: stabilized soil and polymer-modified bitumen approach for cost and carbon efficiency. Multiscale and Multidiscip. Model. Exp. and Des. 7, 1185–1196 (2024). https://doi.org/10.1007/s41939-023-00275-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-023-00275-5