Abstract

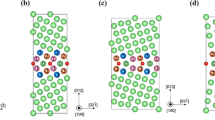

Grain boundaries (GBs) have critical influences on the stability and properties of various materials. In this study, first-principles calculations were performed to determine the effects of four metallic impurities (Ni, Al, Bi, and Pb) and three nonmetallic impurities (H, O, and N) on the GBs of silicon carbide (SiC), using the Σ5(210) GBs as models. The GB energy and segregation energy (SE) were calculated to identify the effects of impurities on the GB stability. Electronic interactions considerably influenced the bonding effects of SiC. The formation of weak bonds resulted in the corrosion and embrittlement of GBs. The co-segregation of Bi, Pb, and O was also investigated in detail.

Similar content being viewed by others

References

X. Shi, B. Li, H. Liu et al., The corrosion resistance mechanisms of the Cr-coated SiC in molten Na2SO4 salt: strengthened boundaries and protective scales. Corros. Sci. 185, 109421 (2021). https://doi.org/10.1016/j.corsci.2021.109421

S.L. Chen, X.J. He, C.X. Yuan et al., Recent studies on potential accident-tolerant fuel-cladding systems in light water reactors. Nucl. Sci. Tech. 31, 32 (2020). https://doi.org/10.1007/s41365-020-0741-9

C. Cluzel, E. Baranger, P. Ladevèze et al., Mechanical behavior and lifetime modelling of self-healing ceramic-matrix composites subjected to thermo-mechanical loading in air. Composites A 40, 976–984 (2009). https://doi.org/10.1016/j.compositesa.2008.10.020

Z.X. Tan, J.J. Cai, Neutronic analysis of silicon carbide cladding accident-tolerant fuel assemblies in pressurized water reactors. Nucl. Sci. Tech. 30, 48 (2019). https://doi.org/10.1007/s41365-019-0575-5

S. Kondo, M. Lee, T. Hinoki et al., Effect of irradiation damage on hydrothermal corrosion of SiC. J. Nucl. Mater. 464, 36–42 (2015). https://doi.org/10.1016/j.jnucmat.2015.04.034

B. Wang, C. Zhang, X. Ma et al., Key problems on the mechanical behavior of nuclear materials and structures of pressured water reactors. Sci. Sin. Phys. Mech. Astron. 49, 114602 (2019). https://doi.org/10.1360/SSPMA-2019-0113

S. Kondo, S. Mouri, Y. Hyodo et al., Role of irradiation-induced defects on SiC dissolution in hot water. Corros. Sci. 112, 402–407 (2016). https://doi.org/10.1016/j.corsci.2016.08.007

S. Kondo, K. Seki, Y. Maeda et al., Contribution of dangling-bonds to polycrystalline SiC corrosion. Scr. Mater. 188, 6–9 (2020). https://doi.org/10.1016/j.scriptamat.2020.07.001

C.M. Parish, K.A. Terrani, Y.J. Kim et al., Microstructure and hydrothermal corrosion behavior of NITE-SiC with various sintering additives in LWR coolant environments. J. Eur. Ceram. Soc. 37, 1261–1279 (2017). https://doi.org/10.1016/j.jeurceramsoc.2016.11.033

P.J. Doyle, S. Zinkle, S.S. Raiman, Hydrothermal corrosion behavior of CVD SiC in high temperature water. J. Nucl. Mater. 539, 152241 (2020). https://doi.org/10.1016/j.jnucmat.2020.152241

S. Özkan, G. Hapç, G. Orhan et al., Electrodeposited Ni/SiC nanocomposite coatings and evaluation of wear and corrosion properties. Surf. Coat. Technol. 232, 734–741 (2013). https://doi.org/10.1016/j.surfcoat.2013.06.089

V. Zarghami, M. Ghorbani, Alteration of corrosion and nano mechanical properties of pulse electrodeposited Ni/SiC nanocomposite coatings. J. Alloys Compd. 598, 236–242 (2014). https://doi.org/10.1016/j.jallcom.2014.01.220

T.M. Kondo, M. Kondo, Corrosion resistance of ceramics SiC and Si3N4 in flowing lead-bismuth eutectic. Prog. Nucl. Energy 53, 1061–1065 (2011). https://doi.org/10.1016/j.pnucene.2011.04.023

L.Y. He, G.C. Li, S.P. Xia et al., Effect of 37Cl enrichment on neutrons in a molten chloride salt fast reactor. Nucl. Sci. Tech. 31, 27 (2020). https://doi.org/10.1007/s41365-020-0740-x

R. Tu, Q. Liu, Y. Li et al., First principles calculations for iodine atom diffusion in SiC with point defects. Comput. Mater. Sci. 142, 427–436 (2018). https://doi.org/10.1016/j.commatsci.2017.10.025

D. Shrader, L. Szlufarska, D. Morgan, Cs diffusion in cubic silicon carbide. J. Nucl. Mater. 421, 89–96 (2012). https://doi.org/10.1016/j.jnucmat.2011.11.051

D. Shrader, S.M. Khalil, T. Gerczak et al., Ag diffusion in cubic silicon carbide. J. Nucl. Mater. 408, 257–271 (2011). https://doi.org/10.1016/j.jnucmat.2010.10.088

P.F. Zhang, Y.L. Zhang, W. Gai et al., Oxidation behaviour of SiC ceramic coating for C/C composites prepared by pressure-less reactive sintering in wet oxygen: Experiment and first-principle simulation. Ceram. Int. 47, 15337–15348 (2021). https://doi.org/10.1016/j.ceramint.2021.02.099

P. Qing, N.J. Chen, W.F. Skerjanc et al., Reveal the fast and charge-insensitive lattice diffusion of silver in cubic silicon carbide via first-principles calculations. Comput. Mater. Sci. 170, 109190 (2019). https://doi.org/10.1016/j.commatsci.2019.109190

T.M. Lillo, I.J. Rooyen, Influence of SiC GB character on fission product transport in irradiated TRISO fuel. J. Nucl. Mater. 473, 83–92 (2016). https://doi.org/10.1016/j.jnucmat.2016.01.040

A. Lara, A. Muñoz, M. Castillo-Rodríguez et al., High-temperature compressive creep of spark-plasma sintered additive-free polycrystalline β-SiC. J. Eur. Ceram. Soc. 32, 3445–3451 (2012). https://doi.org/10.1016/j.jeurceramsoc.2012.04.041

B. Wei, J. Zhou, Z. Yao et al., The effect of Ag nanoparticles content on dielectric and microwave absorption properties of β-SiC. Ceram. Int. 46, 5788–5798 (2020). https://doi.org/10.1016/j.ceramint.2019.11.029

T. Koyanagi, Y. Katoh, T. Hinoki et al., Progress in development of SiC-based joints resistant to neutron irradiation. J. Eur. Ceram. Soc. 40, 1023–1034 (2020). https://doi.org/10.1016/j.jeurceramsoc.2019.10.055

Z.F. Huang, F. Chen, Q. Shen et al., Combined effects of nonmetallic impurities and planned metallic dopants on GB energy and strength. Acta. Mater. 166, 113–125 (2019). https://doi.org/10.1016/j.actamat.2018.12.031

Z.F. Huang, F. Chen, Q. Shen et al., Uncovering the influence of common nonmetallic impurities on the stability and strength of a Σ5 (310) GB in Cu. Acta. Mater. 148, 110–122 (2018). https://doi.org/10.1016/j.actamat.2018.01.058

D. Scheiber, K. Prabitz, The influence of alloying on Zn liquid metal embrittlement in steels. Acta. Mater. 195, 750–760 (2020). https://doi.org/10.1016/j.actamat.2020.06.001

M.H. Razmpoosh, C. DiGiovanni, Y.N. Zhou et al., Pathway to understand liquid metal embrittlement (LME) in Fe-Zn couple: From fundamentals toward application. Prog. Mater. Sci. 29, 100798 (2021). https://doi.org/10.1016/j.pmatsci.2021.100798

H. Liang, X. Yao, J.X. Zhang et al., The effect of rare earth oxides on the pressureless liquid phase sintering of α-SiC. J. Euro. Ceram. Soc. 34, 2865–2874 (2014). https://doi.org/10.1016/j.jeurceramsoc.2014.03.029

L. Tan, T.R. Allena, J.D. Hunn et al., EBSD for microstructure and property characterization of the SiC coating in TRISO fuel particles. J. Nucl. Mater. 372, 400–404 (2008). https://doi.org/10.1016/j.jnucmat.2007.04.048

S. Xu, X. Li, Y. Zhao et al., Micromechanical properties and microstructural evolution of Amosic-3 SiC/SiC composites irradiated by silicon ions. J. Eur. Ceram. Soc. 8, 2811–2820 (2020). https://doi.org/10.1016/j.jeurceramsoc.2020.02.023

B. Li, H. Liu, T. Shen et al., Irradiation induced microstructure damage in He-irradiated 3C-SiC at 1000. J. Eur. Ceram. Soc. 40, 1014–1022 (2019). https://doi.org/10.1016/j.jeurceramsoc.2019.11.026

K. Jina, C. Lu, L.M. Wang et al., Effects of compositional complexity on the ion-irradiation induced swelling and hardening in Ni-containing equiatomic alloys. Scr. Mater. 119, 65–70 (2016). https://doi.org/10.1016/j.scriptamat.2016.03.030

F.A. Garner, M.B. Toloczko, B.H. Sencer, Comparison of swelling and irradiation creep behavior of fcc-austenitic and bcc-ferritic/martensitic alloys at high neutron exposure. J. Nucl. Mater. 276, 123–142 (2000). https://doi.org/10.1016/S0022-3115(99)00225-1

L.M. Wang, R.A. Dodd, G.L. Kulcinski et al., Effects of 14 MeV nickel ion irradiation on nickel-copper alloys observed in cross-section. J. Nucl. Mater. 155–157, 1241–1248 (1988). https://doi.org/10.1016/0022-3115(88)90504-1

G. Chen, Y. Lei, Q. Zhu et al., Corrosion behavior of CLAM steel weld bead in flowing Pb-Bi at 550 °C. J. Nucl. Mater. 515, 187–198 (2018). https://doi.org/10.1016/j.jnucmat.2018.12.038

P.G. Baranov, A.P. Bundakova, A.A. Soltamova et al., Silicon vacancy in SiC as a promising quantum system for single-defect and single-photon spectroscopy. Phys. Rev. B 83, 125203 (2011). https://doi.org/10.1103/PhysRevB.83.125203

J.R. Weber, W.F. Koehl, J.B. Varley et al., Quantum computing with defects. Proc. Natl. Acad. Sci. USA 107, 8513–8518 (2010). https://doi.org/10.1073/pnas.1003052107

E.P. Loewen, A.T. Tokuhiro, Status of research and development of the lead alloy cooled fast reactor. J. Nucl. Sci. Technol. 40, 614–627 (2003). https://doi.org/10.1080/18811248.2003.9715398

B.S. Lou, C.A. Yen, Y. Chen et al., Effects of processing parameters on the adhesion and corrosion resistance of oxide coatings grown by plasma electrolytic oxidation on AZ31 magnesium alloys. J. Mater. Sci. Technol. 10, 1355–1371 (2021). https://doi.org/10.1016/j.jmrt.2020.12.108

L. Lin, Y. Chen, L. Hua et al., Electronic structures and ferromagnetism of 3C-SiC doped with (Fe, Co) double-impurities by first-principles calculations. Mater. Sci. Semicon. Proc. 129, 105779 (2021). https://doi.org/10.1016/j.mssp.2021.105779

P. Zhang, Y. Zhang, Initial oxidation of 3C-SiC (111) in oxidizing atmosphere containing water vapor: H2O adsorption from first-principles calculation. Mater. Today. Commun. 26, 102072 (2021). https://doi.org/10.1016/j.mtcomm.2021.102072

B. Li, H. Liu, T. Shen et al., Irradiation-induced microstructure damage in He-irradiated 3C-SiC at 1000°C. J. Eur. Ceram. Soc. 40, 1014–1022 (2019). https://doi.org/10.1016/j.jeurceramsoc.2019.11.026

J. Hui, W. Liu, B. Wang, Theoretical study of the effects of alloying elements on Cu nanotwins. Sci. China-Phys. Mech. Astron. 63, 104612 (2020)

J. Hui, X.Y. Zhang, W. Liu et al., First-principles study of de-twinning in a FCC alloy. J. Sol. State Chem. 293, 121765 (2021). https://doi.org/10.1016/j.jssc.2020.121765

G. Kresse, J. Furthmuller, Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B. 54, 11169–11186 (1996)

W. Kohn, L.J. Sham, Self-consistent equations including exchange and correlation effects. Phys. Rev. B. 140, A1133 (1965)

P.E. Blöchl, Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994)

W. Gordy, W.J.O. Thomas, Electronegativities of the elements. J. Chem. Phys. 24, 439–444 (1956). https://doi.org/10.1063/1.1742493

T.W. Fan, Z.P. Wang, J.J. Lin et al., First-principles predictions for stabilizations of multilayer nanotwins in Al alloys at finite temperatures. J. Alloys Compd. 783, 765–771 (2019). https://doi.org/10.1016/j.jallcom.2018.12.314

A. Kumar, J. Wang, C.N. Tomé et al., First-principles study of energy and atomic solubility of twinning-associated boundaries in hexagonal metals. Acta. Mater. 85, 144–154 (2015). https://doi.org/10.1016/j.actamat.2014.11.015

Q.Y. Wang, C. Wang, Molecular dynamics analysis of the thermal conductivity of SiC grain boundaries under irradiation conditions. J. Mater. Sci. Eng. 34, 133–136 (2016). https://doi.org/10.14136/j.cnki.issn1673-2812.2016.01.025

S. Dinda, W.R. Warke, The effect of grain boundary segregation on liquid metal induced embrittlement of steel. Mater. Sci. Eng. 24, 199–208 (1976). https://doi.org/10.1016/0025-5416(76)90113-0

M. Vsianska, M. Šob, The effect of segregated sp-impurities on grain-boundary and surface structure, magnetism and embrittlement in nickel. Prog. Mater. Sci. 56, 817–840 (2011). https://doi.org/10.1016/j.pmatsci.2011.01.008

C. He, Z. Li, H. Chen et al., Unusual solute segregation phenomenon in coherent twin boundaries. Nat. Commun. 12, 722 (2021). https://doi.org/10.1038/s41467-021-21104-8

X.J. Zhao, H.W. Chen, N. Wilson et al., Direct observation and impact of cosegregated atoms in magnesium having multiple alloying elements. Nat. Commun. 10, 3243 (2019)

Y.M. Zhu, S.W. Xu, J.F. Nie et al., 1011 Twin boundary structures in a Mg–Gd alloy. Acta Mater 143, 1–12 (2018). https://doi.org/10.1016/j.actamat.2017.09.067

H. Zhou, G.M. Cheng, X.L. Ma et al., Effect of Ag on interfacial segregation in MgGdYAgZr alloy. Acta Mater. 95, 20–29 (2015). https://doi.org/10.1016/j.actamat.2015.05.020

X.F. Chen, L.R. Xiao, Z.G. Ding et al., Atomic segregation at twin boundaries in a MgAg alloy. Scr. Mater. 178, 193–197 (2020). https://doi.org/10.1016/j.scriptamat.2019.11.025

L. Pauling, Atomic radii and interatomic distances in metals. J. Am. Chem. Soc. 69, 542–553 (1947)

A.M. Kueck, D.J. He, Two-stage sintering inhibits abnormal grain growth during beta to alpha transformation in SiC. J. Eur. Ceram. Soc. 28, 2259–2264 (2008). https://doi.org/10.1016/j.jeurceramsoc.2008.01.026

Q.Q. Shao, L.H. Liu, T.W. Fan et al., Effects of solute concentration on the stacking fault energy in copper alloys at finite temperatures. J. Alloys Compd. 726, 601–607 (2017). https://doi.org/10.1016/j.jallcom.2017.07.332

L. Huber, J. Rottler, M. Militzer, Atomistic simulations of the interaction of alloying elements with grain boundaries in Mg. Acta Mater. 80, 194–204 (2014). https://doi.org/10.1016/j.actamat.2014.07.047

P. Garg, I. Adlakha, K.N. Solanki, Effect of solutes on ideal shear resistance and electronic properties of magnesium: a first-principles study. Acta. Mater. 153, 327–335 (2018). https://doi.org/10.1016/j.actamat.2018.05.014

C.L. White, W.A. Coghlan, The spectrum of binding energies approach to GB segregation. Metall. Trans. A 8, 1403–1412 (1977)

J. Hui, W. Liu, B. Wang, Quasi-gradient variation of microstructures and properties of Cu–Sn alloy along the thickness direction under cold spinning. J. Alloys Compd. 831, 154701 (2020). https://doi.org/10.1016/j.jallcom.2020.154701

R. Janisch, C. Elsässer, Segregated light elements at grain boundaries in niobium and molybdenum. Phys. Rev. B. 67, 2209–2219 (2003)

C.T. Ser, A.M. Mak, T. Wejrzanowski et al., Designing piezoresistive materials from first-principles: dopant effects on 3C-SiC. Comp. Mater. Sci. 186, 110040 (2021). https://doi.org/10.1016/j.commatsci.2020.110040

M. Luo, Y.E. Xu, Y.X. Song et al., Impact of isotropic strain on electronic and magnetic properties of O-adsorbed SiC monolayer. Mater. Sci. Semicond. Process. 83, 27–32 (2018). https://doi.org/10.1016/j.mssp.2018.04.005

P. Lejcek, Grain boundary segregation in metals. Springer Ser. Mater. Sci. 136, 1–239 (2010). https://doi.org/10.1007/978-3-642-12505-8

D. Scheiber, L. Romaner, R. Pippan et al., Impact of solute-solute interactions on grain boundary segregation and cohesion in molybdenum. Phys. Rev. Mater. 2, 93609 (2018)

J. Hui, G. Yang, M. Liu et al., Effects of alloy compositions on hydrogen behaviors at a nickel grain boundary and a coherent twin boundary. Inter. J. Hydr. Energy 45, 10951–10961 (2020). https://doi.org/10.1016/j.ijhydene.2020.02.008

G.C. Li, Z. Yang, C.G. Yu et al., Influences of 7Li enrichment on Th-U fuel breeding for an improved molten salt fast reactor (IMSFR). Nucl. Sci. Technol. 28, 97 (2017). https://doi.org/10.1007/s41365-017-0250-7

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Jun Hui, Wen-Guan Liu, Bao-Liang Zhang, Tao Liu, and Min Liu. The first draft of the manuscript was written by Jun Hui and Wen-Guan Liu, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Nos. 11832019, 11472313, 11572355, and 11705264), the Science and Technology Plan Project of Guangdong Province (No. 2020A0505020005), the Fundamental Research Funds for the Central Universities (No. 19lgpy298), and the State Key Laboratory of Powder Metallurgy, Central South University, Changsha, China.

Rights and permissions

About this article

Cite this article

Hui, J., Zhang, BL., Liu, T. et al. Effects of impurity elements on SiC grain boundary stability and corrosion. NUCL SCI TECH 32, 125 (2021). https://doi.org/10.1007/s41365-021-00963-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41365-021-00963-2