Abstract

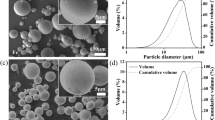

The selectivity between electrically conductive and insulating regions within one additively manufactured part can open new domains for customized, smart, and active products. In this article, new electrically conductive polymer matrix composites (ePMC) were developed for additive manufacturing (AM) by loading an aqueous matrix of carboxymethyl cellulose with micro-sized graphite particles. Electrically conductive AM can be achieved using the developed ePMC with the direct ink writing (DIW) technique. The effects of graphite loading on the properties of ePMCs and their suitability for AM were investigated using various characterization techniques. The non-Newtonian shear-thinning behavior of the ePMC inks indicates the suitability of these inks for DIW. Tunable electrical conductivity in the range of 87–128 S m−1 can be achieved with a 15% margin of error. DIW of scaffolds with rectilinear and honeycomb infill patterns demonstrate the additive manufacturability of the developed ePMCs. Furthermore, an application of additively manufactured and electrically conductive part as a heating element was demonstrated. The developed ePMCs can be employed in diverse applications such as AM of conductive tracks, resistors, and electrodes for capacitors and energy storage devices.

Similar content being viewed by others

References

Wang X, Jiang M, Zhou Z et al (2017) 3D printing of polymer matrix composites: a review and prospective. Compos Part B Eng 110:442–458. https://doi.org/10.1016/J.COMPOSITESB.2016.11.034

Flowers PF, Reyes C, Ye S et al (2017) 3D printing electronic components and circuits with conductive thermoplastic filament. Addit Manuf 18:156–163. https://doi.org/10.1016/J.ADDMA.2017.10.002

Wei X, Li D, Jiang W et al (2015) 3D printable graphene composite. Sci Rep 5:11181. https://doi.org/10.1038/srep11181

Tan JC, Low HY (2018) Embedded electrical tracks in 3D printed objects by fused filament fabrication of highly conductive composites. Addit Manuf 23:294–302. https://doi.org/10.1016/J.ADDMA.2018.06.009

Singh R, Singh H, Farina I et al (2019) On the additive manufacturing of an energy storage device from recycled material. Compos Part B Eng 156:259–265. https://doi.org/10.1016/J.COMPOSITESB.2018.08.080

Sezer HK, Eren O (2019) FDM 3D printing of MWCNT re-inforced ABS nano-composite parts with enhanced mechanical and electrical properties. J Manuf Process 37:339–347. https://doi.org/10.1016/J.JMAPRO.2018.12.004

Farahani RD, Dalir H, Le Borgne V et al (2012) Direct-write fabrication of freestanding nanocomposite strain sensors. Nanotechnology 23:085502. https://doi.org/10.1088/0957-4484/23/8/085502

Zhong J, Zhou G-X, He P-G et al (2017) 3D printing strong and conductive geo-polymer nanocomposite structures modified by graphene oxide. Carbon N Y 117:421–426. https://doi.org/10.1016/J.CARBON.2017.02.102

Areir M, Xu Y, Zhang R et al (2017) A study of 3D printed active carbon electrode for the manufacture of electric double-layer capacitors. J Manuf Process 25:351–356. https://doi.org/10.1016/J.JMAPRO.2016.12.020

Ambrosi A, Pumera M (2016) 3D-printing technologies for electrochemical applications. Chem Soc Rev 45:2740–2755. https://doi.org/10.1039/C5CS00714C

ProtoPlant Electrically Conductive Composite PLA-ProtoPlant, makers of Proto-pasta. https://www.proto-pasta.com/products/conductive-pla?variant=1265211476. Accessed 18 Jun 2019

BLACKMAGIC3D conductive graphene 3D printing PLA filament. https://www.blackmagic3d.com/Conductive-p/grphn-pla.htm. Accessed 17 Jun 2019

Multi3D electrifi conductive filament|Multi3D. https://www.multi3dllc.com/product/electrifi/. Accessed 18 Jun 2019

Pandey JK, Takagi H, Nakagaito AN et al (2012) An overview on the cellulose based conducting composites. Compos Part B Eng 43:2822–2826. https://doi.org/10.1016/J.COMPOSITESB.2012.04.045

Li J, Lewis RB, Dahn JR (2007) Sodium carboxymethyl cellulose. Electrochem Solid State Lett 10:A17. https://doi.org/10.1149/1.2398725

Benchabane A, Bekkour K (2008) Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid Polym Sci 286:1173–1180. https://doi.org/10.1007/s00396-008-1882-2

Lin R, Li A, Lu L, Cao Y (2015) Preparation of bulk sodium carboxymethyl cellulose aerogels with tunable morphology. Carbohydr Polym 118:126–132. https://doi.org/10.1016/J.CARBPOL.2014.10.075

Khaled B, Abdelbaki B (2012) Rheological and electrokinetic properties of carboxymethylcellulose-water dispersions in the presence of salts. Int J Phys Sci 7:1790–1798. https://doi.org/10.5897/IJPS11.1779

Rueschhoff L, Costakis W, Michie M et al (2016) Additive manufacturing of dense ceramic parts via direct ink writing of aqueous alumina suspensions. Int J Appl Ceram Technol 13:821–830. https://doi.org/10.1111/ijac.12557

Kaur G, Adhikari R, Cass P et al (2015) Electrically conductive polymers and composites for biomedical applications. RSC Adv 5:37553–37567. https://doi.org/10.1039/C5RA01851J

Marinho B, Ghislandi M, Tkalya E et al (2012) Electrical conductivity of compacts of graphene, multi-wall carbon nanotubes, carbon black, and graphite powder. Powder Technol 221:351–358. https://doi.org/10.1016/J.POWTEC.2012.01.024

Foo CY, Lim HN, Mahdi MA et al (2018) Three-dimensional printed electrode and its novel applications in electronic devices. Sci Rep. https://doi.org/10.1038/s41598-018-25861-3

Isa MA, Lazoglu I (2019) Five-axis additive manufacturing of freeform models through buildup of transition layers. J Manuf Syst 50:69–80. https://doi.org/10.1016/J.JMSY.2018.12.002

Yigit IE, Lazoglu I (2019) Helical slicing method for material extrusion-based robotic additive manufacturing. Prog Addit Manuf 4:225–232. https://doi.org/10.1007/s40964-019-00090-w

Acknowledgements

This research was supported by the Manufacturing and Automation Research Center, Koc University, Istanbul, Turkey. The authors would like to thank Mitsubishi Electric for providing the industrial robot and Turkish Aerospace Industries for providing the CFRP materials used in this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, Ismail Lazoglu states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Khan, S.A., Lazoglu, I. Development of additively manufacturable and electrically conductive graphite–polymer composites. Prog Addit Manuf 5, 153–162 (2020). https://doi.org/10.1007/s40964-019-00102-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-019-00102-9