Abstract

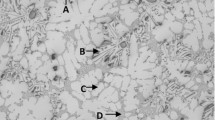

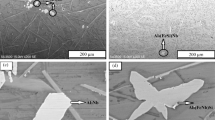

In this paper, several Al–Si–Fe–Mn–Cr alloys were prepared, with different element contents and solidification conditions. The conventional Chinese character-shaped Al15(Fe,Mn)3Si2 particles were detected in slowly solidified Al–12Si–2Fe–4Mn alloy, while both (Al,Si)2Cr and Al15(Fe,Cr)3Si2 particles were formed in slowly solidified Al–12Si–2Fe–4Cr alloy. When the melt was solidified with high cooling speed, all of the α–Al15Fe3Si2-type intermetallics in Al–12Si–2Fe–4Mn, Al–12Si–2Fe–4Cr and Al–12Si–4Fe–xMn–yCr (x + y = 4) alloys exhibit dendrite-like. It was found that the higher Mn (or Cr) addition in Al–12Si–4Fe–xMn–yCr alloys, the higher Mn (or Cr) content in Al15(Fe,Mn,Cr)3Si2 phase. Compared to Mn atoms, Cr atoms have a higher tendentiousness to participate in the formation of Al15(Fe,Mn,Cr)3Si2 intermetallics.

Similar content being viewed by others

References

K. Prabhu, K. Sharath, G. Ramesh, Heat flux transients and casting surface macro–profile during downward solidification of Al–12% Si alloy against chills. Inter. Metalcast. 5, 63–70 (2011). https://doi.org/10.1007/BF03355523

T. Koutsoukis, M.M. Makhlouf, Alternatives to the Al–Si eutectic system in aluminum casting alloys. Inter. Metalcast. 10, 342–347 (2016). https://doi.org/10.1007/s40962-016-0042-6

A.M. Samuel, M.H. Abdelaziz, H.W. Doty, F.H. Samuel, Metallurgical parameters controlling fragmentation and spheroidization processes of eutectic Si particles in Al–Si cast alloys. Inter. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00702-8

J.Q. Gan, J. Du, C. Wen, G.G. Zhang, M.B. Shi, Z.Z. Yuan, The effect of Fe content on the solidification pathway, microstructure and thermal conductivity of hypoeutectic Al–Si Alloys. Inter. Metalcast. 16, 178–190 (2022). https://doi.org/10.1007/s40962-021-00580-0

T. Gao, Y.Y. Wu, C. Li, X.F. Liu, Morphologies and growth mechanisms of α–Al(FeMn)Si in Al–Si–Fe–Mn alloy. Mater. Lett. 10, 191–194 (2013)

C.B. Basak, N.H. Babu, Morphological changes and segregation of β–Al9Fe2Si2 phase: a perspective from better recyclability of cast Al–Si alloys. Mater. Des. 108, 277–288 (2016)

G. Gustafsson, T. Thorvaldsson, G.L. Dunlop, The influence of Fe and Cr on the microstructure of cast Al–Si–Mg alloys. Metall. Mater. Trans. A 17, 45–52 (1986)

N. El-Kaddah, A.D. Patel, T.T. Natarajan, The electromagnetic filtration of molten aluminum using an induced–current separator. JOM 47, 46–49 (1995)

L.A. Narayanan, F.H. Samuel, J.E. Gruzleski, Crystallization behavior of iron–containing intermetallic compounds in 319 aluminum alloy. Metall. Mater. Trans. A 25, 1761–1773 (1994).

H. Matsubara, N. Izawa, M. Nakanishi, Macroscopic segregation in Al–11 mass%Si alloy containing 2 mass%Fe solidified under centrifugal force. J. Japan Ins. Light Metals 48, 93–97 (1998)

M. Alizadeh, M. Karamouz, Effect of periodic melt shearing process and cooling rate on structure and hardness of Al–0.7Fe aluminum alloy. Mater. Des. 55, 204–211 (2014)

Y.H. Zhang, Y.C. Liu, Y.J. Han, C. Wei, Z.M. Gao, The role of cooling rate in the microstructure of Al–Fe–Si alloy with high Fe and Si contents. J. Alloys Compd. 473, 442–445 (2009)

M.F. Ibrahim, S.A. Alkahtani, K.A. Abuhasel, F.H. Samuel, Effect of intermetallics on the microstructure and tensile properties of aluminum based alloys: role of Sr, Mg and Be addition. Mater. Des. 86, 30–40 (2015)

A.M. Samuel, E.M. Elgallad, H.W. Doty, S. Valtierra, F.H. Samuel, On the microstructure, hardness and impact toughness of 356 and 413 alloys. Inter. Metalcast. 11, 240–254 (2017). https://doi.org/10.1007/s40962-016-0066-y

P. Orozco-González, M. Castro-Román, A.I. Martínez, M. Herrera-Trejo, A.A. López, J. Quispe-Marcatoma, Precipitation of Fe–rich intermetallic phases in liquid Al–13.58Si–11.59Fe–1.19Mn alloy. Intermetallics 18(8), 1617–1622 (2010)

S.G. Shabestari, The effect of iron and manganese on the formation of intermetallic compounds in aluminum–silicon alloys. Mater. Sci. Eng. A 383, 289–298 (2004)

H.R. Ammar, A.M. Samuel, F.H. Samuel, Effect of casting imperfections on the fatigue life of 319–F and A356–T6 Al–Si casting alloys. Mater. Sci. Eng. A 473, 65–75 (2008)

C.M. Dinnis, J.A. Taylor, A.K. Dahle, As–cast morphology of iron–intermetallics in Al–Si foundry alloys. Scripta Mater. 53, 955–958 (2005)

Q.G. Wang, C.H. Caceres, J.R. Griffiths, Damage by eutectic particle cracking in aluminum casting alloys A356/357. Metall Mater Trans A 34, 2901–2912 (2003)

Y.G. Li, Y.Y. Wu, Z. Qian, X.F. Liu, Effect of co–addition of RE, Fe and Mn on the microstructure and performance of A390 alloy. Mater. Sci. Eng. A 527, 146–149 (2009)

T. Gao, K.Q. Hu, L.S. Wang, B.R. Zhang, X.F. Liu, Morphological evolution and strengthening behavior of α–Al(Fe, Mn)Si in Al–6Si–2Fe–xMn alloys. Results Phys. 7, 1051–1054 (2017)

H.Y. Kim, T.Y. Park, S.W. Han, H.M. Lee, Effects of Mn on the crystal structure of α–Al(Mn, Fe)Si particles in A356 alloys. J. Cryst. Growth 291, 207–211 (2006)

D.T. Wang, X.Z. Zhang, H. Nagaumi, X.Z. Li, H.T. Zhang, 3D morphology and growth mechanism of cubica–Al(FeMnCr)Si intermetallic in an Al–Si cast alloy. Mater. Lett. 277, 128384 (2020)

M. Galano, F. Audebert, I.C. Stone, B. Cantorc, Nanoquasicrystalline Al–Fe–Cr–based alloys. Part I: Phase transformations. Acta Mater. 57, 5107–5119 (2009)

Materials Data JADE Release 5, XRD Pattern Processing and Materials Data Inc. (MDI), 2002.

L.G. Hou, S. Wang, Z.B. He, D. Zhang, X.D. Wang, L.Z. Zhuang et al., Synthesis and characterization of in situ dendritic/ particulate α–Al(Fe, TM)Si phase reinforced Al matrix composites. Metall. Mater. Trans. A 47A, 6413–6427 (2016)

Y.G. Li, Y. Yang, Y.Y. Wu, Z.S. Wei, X.F. Liu, Supportive strengthening role of Cr–rich phase on Al–Si multicomponent piston alloy at elevated temperature. Mater. Sci. Eng. A 528, 4427–4430 (2011)

M. Cavojsky, M. Balog, J. Dvorak, E. Illekova, P. Svec, P. Krizik et al., Microstructure and properties of extruded rapidly solidified AlCr4.7Fe1.1Si0.3 (at.%) alloys. Mater. Sci. Eng. A 549, 233–241 (2012)

Acknowledgment

This research was financially supported by the Young Scholars Program of Shandong University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, B., Ma, C., Li, L. et al. Morphologies and Compositions of α–Al15Fe3Si2-Type Intermetallics in Al–Si–Fe–Mn–Cr Alloys. Inter Metalcast 17, 1156–1164 (2023). https://doi.org/10.1007/s40962-022-00843-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-022-00843-4