Abstract

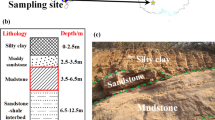

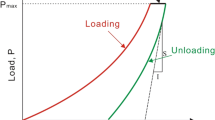

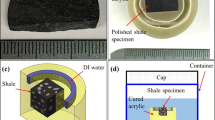

The greenish mudstone in the Fushun West open-pit mine (Fushun city, China), the largest open-pit mine in Asia, is weak due to the presence of clay minerals and may induce the failure and collapse of rock slopes. It is therefore of great importance to accurately assess the mechanical properties of the mudstone. However, due to the properties of mudstone, is it challenging to perform traditional experiments, which require numerous large specimens. In the present paper, nanoindentation experiments were performed to measure the mechanical parameters, such as elastic modulus and indentation hardness, of the greenish mudstone from the Fushun West open-pit mine at the microscale. These microscale properties were upscaled to the centimeter scale using the K-means and Mori–Tanaka methods. A numerical model was then built to perform nanoindentation simulations, the results of which are in good agreement with the nanoindentation experiments. A dual-indentation technique was then used to obtain the cohesion and the angle of internal friction of the mudstone from the experiments and simulations. Finally, our mechanical data were compared with data from a uniaxial compressive strength experiment. Although the upscaled values from the nanoscale experiments and models by Berkovich indenter are slightly higher than the values determined from the uniaxial experiment, and can be explained by the increase in void space at longer length-scales, we conclude that the methods employed here can be used to determine the upscaled mechanical properties important for slope stability analyses and safety assessments of the Fushun West open-pit mine.

Article Highlights

-

The nanoindentation on weak and friable mudstones to obtain the hardness and elastic modulus of the weak mudstone at micro-scale.

-

A three-phase medium micromechanical model based on low-, medium-, and high-strength minerals was proposed to upscale macroscopic properties of greenish mudstone.

-

Upscaled mechanical properties of the weak mudstone are basically consistent with those from traditional laboratory experiments.

Similar content being viewed by others

References

Anderson RL, Ratcliffe I, Greenwell HC, Williams PA, Cliffe S, Coveney PV (2010) Clay swelling—a challenge in the oilfield. Earth-Sci Rev 98:201–216

Bandara KMAS, Ranjith PG, Kumari WGP (2021) A coupled X-ray imaging and experimental permeability study of propped hydraulically induced fractures. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-021-02566-0

Bandini A, Berry P, Bemporad E, Sebastiani M (2012) Effects of intra-crystalline microcracks on the mechanical behavior of a marble under indentation. Int J Rock Mech Min Sci 54:47–55

Basu S, Zhou A, Barsoum MW (2009) On spherical nanoindentations, kinking nonlinear elasticity of mica single crystals and their geological implications. J Struct Geol 31:791–801

Bobko C, Ulm FJ (2008) The nano-mechanical morphology of shale. Mech Mater 40:318–337

Bolshakov A, Pharr GM (1998) Influences of pileup on the measurement of mechanical properties by load and depth sensing indentation techniques. J Mater Res 13:1049–1058

Chen L-Q (2002) Phase-field models for microstructure evolution. Annu Rev Mater Res 32:113–113

Cheng YT, Li Z, Cheng CM (2002) Scaling relationships for indentation measurements. Philos Mag A 82:1821–1829

Constantinides G, Chandran KS, Ravi UFJ, Van VKJ (2006) Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater Sci Eng, A 430:189–202

Evans B, Goetze C (1979) The temperature variation of hardness of olivine and its implication for polycrystalline yield stress. J Geophys Res: Solid Earth 84:5505–5524

Fischer-Cripps AC (2011) Nanoindentation, 3rd edn. Springer-Verlag, New York

Fu TF, Xu T, Heap MJ, Meredith PG, Mitchell TM (2020) Mesoscopic time-dependent behavior of rocks based on three-dimensional discrete element grain-based model. Comput Geotech 121:103472

Ganneau FP, Constantinides G, Ulm FJ (2006) Dual-indentation technique for the assessment of strength properties of cohesive-frictional materials. Int J Solids Struct 43:1727–1745

Hay J (2010) Introduction to instrumented indentation testing. Exp Tech 33:66–72

Heap MJ, Villeneuve M, Kushnir AR, Farquharson JI, Baud P, Reuschlé T (2019) Rock mass strength and elastic modulus of the Buntsandstein: An important lithostratigraphic unit for geothermal exploitation in the Upper Rhine Graben. Geothermics 77:236–256

Heap MJ, Villeneuve M, Albino F, Farquharson JI, Brothelande E, Amelung F, Got JL, Baud P (2020) Towards more realistic values of elastic moduli for volcano modelling. J Volcanol Geotherm Res 390:106684

Knapp JA, Follstaedt DM, Myers SM, Barbour JC, Friedmann TA, Jwa I, Monteiro OR, Brown IG (1998) Finite-element modeling of nanoindentation for evaluating mechanical properties of MEMS materials. Surf Coat Technol 103:268–275

Kumamoto KM, Thom CA, Wallis D, Hansen LN, Armstrong DEJ, Warren JM, Goldsby DL, Wilkinson AJ (2017) Size effects resolve discrepancies in 40 years of work on low-temperature plasticity in olivine. Sci Adv 3:e1701338

Lichinchi M, Lenardi C, Haupt J, Vitali R (1998) Simulation of Berkovich nanoindentation experiments on thin films using finite element method. Thin Solid Films 333:240–248

Liu K, Ostadhassan M, Bubach B (2018a) Application of nanoindentation to characterize creep behavior of oil shales. J Petrol Sci Eng 167:729–736

Liu K, Ostadhassan M, Bubach B, Ling K, Tokhmechi B, Robert D (2018) Statistical grid nanoindentation analysis to estimate macro-mechanical properties of the Bakken Shale. J Nat Gas Sci Eng 53:181–190

Loubet JL, Georges JM, Marchesini O, Meille G (1984) Vickers indentation curves of magnesium oxide (MgO). J Lubr Technol 106:43

Lu CJ, Bogy DB (1995) The effect of tip radius on nano-indentation hardness tests. Int J Solids Struct 32(12):1759–1770

Lu Y, Wang L, Sun X, Wang J (2016) Experimental study of the influence of water and temperature on the mechanical behavior of mudstone and sandstone. Bull Eng Geol Env 76:1–16

Lu Y, Li Y, Wu Y, Luo S, Zhang G (2020) Characterization of shale softening by large volume-based nanoindentation. Rock Mech Rock Eng 53:1393–1409

Ma Z, Gamage RP, Zhang C (2020) Application of nanoindentation technology in rocks: a review. Geomech Geophys Geo-energ Geo-resour. https://doi.org/10.1007/s40948-020-00178-6

Ma Z, Gamage RP, Zhang C (2021) Mechanical properties of α-quartz using nanoindentation tests and molecular dynamics simulations. Int J Rock Mech Min Sci 147:104878

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall 21:571–574

Newey D, Wilkins MA, Pollock HM (1982) An ultra-low-load penetration hardness tester. J Phys E: Sci Instrum 15:119–122

Oliver GJ (1992) XRF analysis of ceramics minerals and allied materials. John Wiley and Sons Ltd., UK

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Randall NX, Vandamme M, Ulm FJ (2009) Nanoindentation analysis as a two-dimensional tool for mapping the mechanical properties of complex surfaces. J Mater Res 24:679–690

Rathnaweera TD, Ranjith PG, Gu X, Perera MSA, Kumari WGP, Wanniarachchi WAM, Haque A, Li JC (2018) Experimental investigation of thermomechanical behaviour of clay-rich sandstone at extreme temperatures followed by cooling treatments. Int J Rock Mech Min Sci 107:208–223

Rong Y, Zhang T, Peng J, Bai Y (2008) Experimental verification and theoretical analysis of the relationships between hardness, elastic modulus, and the work of indentation. Appl Phys Lett 92:1564

Shi X, Jiang S, Lu SF, He ZL, Li DJ, Wang ZX, Xiao DS (2019) Investigation of mechanical properties of bedded shale by nanoindentation tests: a case study on lower silurian longmaxi formation of Youyang area in southeast Chongqing, China. Pet Explor Dev 46:155–164

Sneddon IN (1965) The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int J Eng Sci 3:47–57

Stone D, Lafontaine WR, Alexopoulos P, Wu TW, Li CY (1988) An investigation of hardness and adhesion of sputter-deposited aluminum on silicon by utilizing a continuous indentation test. J Mater Res 3:141–147

Sun C, Li G, Gomah ME, Xu J, Sun Y (2020) Creep characteristics of coal and rock investigated by nanoindentation. Int J Min Sci Technol 30(6):769–776

Sun C, Li G, Gomah ME, Xu J, Rong H (2020a) Meso-scale mechanical properties of mudstone investigated by nanoindentation. Eng Fract Mech. https://doi.org/10.1016/j.engfracmech.2020.107245

Villeneuve MC, Heap MJ, Kushnir AR, Qin T, Baud P, Zhou G, Xu T (2018) Estimating in situ rock mass strength and elastic modulus of granite from the Soultz-sous-Forêts geothermal reservoir (France). Geotherm Energy 6(1):1–29

Wong JA, Hartiganm A (1979) Algorithm AS 136: a K-means clustering algorithm. J Roy Stat Soc 28:100–108

Xu J, Tang X, Wang Z, Feng Y, Bian K (2020) Investigating the softening of weak interlayers during landslides using nanoindentation experiments and simulations. Eng Geol. https://doi.org/10.1016/j.enggeo.2020.105801

Xu T, Fu TF, Heap MJ, Meredith PG, Mitchell TM, Baud P (2020b) Mesoscopic damage and fracturing of heterogeneous brittle rocks based on three-dimensional polycrystalline discrete element method. Rock Mech Rock Eng 53(12):5389–5409

Xu Tao Fu, Meng Yang Sheng-qi, Heap Michael J, Guang-lei Zhou (2021) A numerical meso-scale elasto-plastic damage model for modeling the deformation and fracturing of sandstone under cyclic loading. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-021-02556-2

Yu XY, Tao Xu, Heap MJ, Patrick Baud, Thierry Reuschlé, Zhen Heng, Zhu WC, Wang XW (2021) Time-dependent deformation and failure of granite based on the virtual crack incorporated numerical manifold method. Comput Geotech 133:104070

Yuan Y, Xu T, Heap Michael J, Meredith Philip G, Yang T, Zhou G (2021) A three-dimensional mesoscale model for progressive time-dependent deformation and fracturing of brittle rock with application to slope stability. Comput Geotech 135:104160

Zhou GL, Xu T, Zhu WC, Konietzky H, Heng Z, Yu X (2020) A damage-based numerical manifold approach to crack propagation in rocks. Eng Anal Bound Elem 117:76–88

Zhou Guang-lei Xu, Tao KH, Wancheng Z, Heng Zhen Yu, Xian-yang ZY (2022) An improved grain-based numerical manifold method to simulate deformation, damage and fracturing of rocks at the grain size level. Eng Anal Bound Elem 134:107–116

Zhu Y, Yao YX, Zhou L (2004) Nano-indentation technology and its experimental research. Tool Eng 8:13–16

Acknowledgements

The work was jointly supported by NSFC (51974062, 42172312, 51950410595), National Key Research and Development Program of China (2017YFC1503100), and Fundamental Research Funds for the Central Universities of China (N180101028). M. Heap acknowledges support from the Institut Universitaire de France (IUF).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lu, J., Xu, T., Tang, X. et al. Nanoindentation-based characterization of micromechanical properties of greenish mudstone from deep Fushun West open-pit mine (Fushun city, China). Geomech. Geophys. Geo-energ. Geo-resour. 8, 59 (2022). https://doi.org/10.1007/s40948-022-00371-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-022-00371-9