Abstract

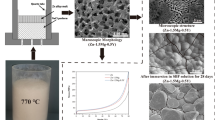

Forming a stable anti-corrosion surface layer on magnesium (Mg) and its alloys has become a major challenge in developing a desirable degradable medical implant in bone. In this study, a porous MgO layer was first formed on Mg by plasma electrolytic oxidation (PEO), and then a Mg-Al layered double hydroxide (LDH) layer was prepared to seal the porous structure of the PEO layer (LDH-2h and LDH-12h) via hydrothermal treatment. The bilayer structure composite coating, which can effectively resist the penetration of surrounding media, is similar to plain Chinese tiles. The in vitro results revealed that compared with other coatings, the LDH-12h composite coating can reduce the release of Mg ions and induce a milder change in pH when immersed in phosphate-buffered saline (PBS). In vitro rat bone marrow stem cell (rBMSC) culture suggested that the LDH-12h composite coating is favorable for cell activity, proliferation and could improve the osteogenic activity of rBMSCs. A subcutaneous implantation test revealed that the as-prepared sample showed enhanced corrosion resistance and histocompatibility in vivo, especially in the LDH-12h group. Moreover, LDH-12h had the lowest rate of degradation and the closest combination with the new bone after being inserted into a rat femur for 12 weeks with no major organ dysfunction. In summary, the asprepared PEO/Mg-Al LDH composite coating is able to improve the corrosion resistance and biocompatibility of Mg and to enhance osteogenic activity in vivo, suggesting its promising prospects for orthopedic applications.

摘要

镁(Mg)及其合金因具有生物可降解和促成骨效应而成为理想的骨内固定材料, 但其抗腐蚀能力差、 体内降解快的缺点限制了其临床应用. 开发稳定的防腐涂层是镁基金属临床应用的主要挑战. 本研究首先通过等离子体电解氧化法(PEO)在Mg表面形成多孔的PEO涂层, 然后通过水热处理制备Mg-Al层状双氢氧化物(LDH)层来封闭MgO层的多孔结构(根据处理时间不同分为LDH-2h和LDH-12h组). 体外实验结果表明, 与其他涂层相比, LDH-12h 组在磷酸盐缓冲液(PBS)中可以有效减少Mg2+释放并抑制pH值变化. 另外, LDH-12h组促进了大鼠骨髓干细胞(rBMSC)的生物活性、 增殖速率以及成骨活性. 大鼠皮下植入试验表明, 经过改性的纯镁金属在体内的耐蚀性和组织相容性增加, 尤其是LDH-12h组. 此外, LDH-12h组植入大鼠股骨12周后降解率最低、 与新生骨结合最紧密, 并且未发现主要器官功能障碍. 本研究所制备的PEO/Mg-Al LDH复合涂层能够明显改善Mg的耐蚀性和生物相容性, 增强体内成骨活性, 具有良好的临床应用前景.

Similar content being viewed by others

References

Fuglsig JMCS, Thorn JJ, Ingerslev J, et al. Long term follow-up of titanium implants installed in block-grafted areas: A systematic review. Clin Implant Dent Relat Res, 2018, 20: 1036–1046

Geetha M, Singh AK, Asokamani R, et al. Ti based biomaterials, the ultimate choice for orthopaedic implants: A review. Prog Mater Sci, 2009, 54: 397–425

Liu X, Chu P, Ding C. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng-R-Rep, 2004, 47: 49–121

Abdel-Hady Gepreel M, Niinomi M. Biocompatibility of Ti-alloys for long-term implantation. J Mech Behav Biomed Mater, 2013, 20: 407–415

Albrektsson T, Chrcanovic B, Molne J, et al. Foreign body reactions, marginal bone loss and allergies in relation to titanium implants. Euro J Oral Implantol, 2018, 11: S37–S46

Song MS, Zeng RC, Ding YF, et al. Recent advances in biodegradation controls over Mg alloys for bone fracture management: A review. J Mater Sci Tech, 2019, 35: 535–544

Ali M, Hussein MA, Al-Aqeeli N. Magnesium-based composites and alloys for medical applications: A review of mechanical and corrosion properties. J Alloys Compd, 2019, 792: 1162–1190

Windhagen H, Radtke K, Weizbauer A, et al. Biodegradable magnesium-based screw clinically equivalent to titanium screw in hallux valgus surgery: Short term results of the first prospective, randomized, controlled clinical pilot study. Biomed Eng Online, 2013, 12: 62

Witte F. The history of biodegradable magnesium implants: A review. Acta Biomater, 2010, 6: 1680–1692

Huse E. A new ligature. Chicago Med J Exam, 1878, 172(2)

Yu Y, Lu H, Sun J. Long-term in vivo evolution of high-purity Mg screw degradation: Local and systemic effects of Mg degradation products. Acta Biomater, 2018, 71: 215–224

Han P, Cheng P, Zhang S, et al. In vitro and in vivo studies on the degradation of high-purity Mg (99.99 wt%) screw with femoral intracondylar fractured rabbit model. Biomaterials, 2015, 64: 57–69

Chen S, Zhang J, Chen Y, et al. Application of phenol/amine copolymerized film modified magnesium alloys: Anticorrosion and surface biofunctionalization. ACS Appl Mater Interfaces, 2015, 7: 24510–24522

Peng F, Li H, Wang D, et al. Enhanced corrosion resistance and biocompatibility of magnesium alloy by Mg-Al-layered double hydroxide. ACS Appl Mater Interfaces, 2016, 8: 35033–35044

Yin ZZ, Qi WC, Zeng RC, et al. Advances in coatings on biodegradable magnesium alloys. J Magnesium Alloys, 2020, 8: 42–65

Cui LY, Zeng RC, Guan SK, et al. Degradation mechanism of micro-arc oxidation coatings on biodegradable Mg-Ca alloys: The influence of porosity. J Alloys Compd, 2017, 695: 2464–2476

Xiong Y, Lu C, Wang C, et al. The n-MAO/EPD bio-ceramic composite coating fabricated on ZK60 magnesium alloy using combined micro-arc oxidation with electrophoretic deposition. Appl Surf Sci, 2014, 322: 230–235

Yang YX, Fang Z, Liu YH, et al. Biodegradation, hemocompatibility and covalent bonding mechanism of electrografting polyethylacrylate coating on Mg alloy for cardiovascular stent. J Mater Sci Tech, 2020, 46: 114–126

Gao YL, Liu Y, Song XY. Plasma-sprayed hydroxyapatite coating for improved corrosion resistance and bioactivity of magnesium alloy. J Therm Spray Tech, 2018, 27: 1381–1387

Duan G, Yang L, Liao S, et al. Designing for the chemical conversion coating with high corrosion resistance and low electrical contact resistance on AZ91D magnesium alloy. Corros Sci, 2018, 135: 197–206

Narayanan TSNS, Park IS, Lee MH. Strategies to improve the corrosion resistance of microarc oxidation (MAO) coated magnesium alloys for degradable implants: Prospects and challenges. Prog Mater Sci, 2014, 60: 1–71

Jovović J, Stojadinović S, Šišović NM, et al. Spectroscopic study of plasma during electrolytic oxidation of magnesium- and aluminium-alloy. J Quant Spectrosc Radiat Transfer, 2012, 113: 1928–1937

Zhang L, Zhang J, Chen C, et al. Advances in microarc oxidation coated AZ31 Mg alloys for biomedical applications. Corros Sci, 2015, 91: 7–28

Zhang ZQ, Wang L, Zeng MQ, et al. Biodegradation behavior of micro-arc oxidation coating on magnesium alloy-from a protein perspective. Bioact Mater, 2020, 5: 398–409

Zeng RC, Cui L, Jiang K, et al. In vitro corrosion and cytocompatibility of a microarc oxidation coating and poly(L-lactic acid) composite coating on Mg-1Li-1Ca alloy for orthopedic implants. ACS Appl Mater Interfaces, 2016, 8: 10014–10028

Guo L, Wu W, Zhou Y, et al. Layered double hydroxide coatings on magnesium alloys: A review. J Mater Sci Tech, 2018, 34: 1455–1466

Peng F, Wang D, Tian Y, et al. Sealing the pores of PEO coating with Mg-Al layered double hydroxide: Enhanced corrosion resistance, cytocompatibility and drug delivery ability. Sci Rep, 2017, 7: 8167

El-Rahman S. Neuropathology of aluminum toxicity in rats (glutamate and GABA impairment). Pharmacol Res, 2003, 47: 189–194

Kumar V, Gill KD. Aluminium neurotoxicity: Neurobehavioural and oxidative aspects. Arch Toxicol, 2009, 83: 965–978

Lubkowska A, Chlubek D. Aluminum in the human environment —Absorption and toxicity. Trace Elements and Electrolyt, 2015, 32: 52–59

Zhang G, Wu L, Tang A, et al. Growth behavior of MgAl-layered double hydroxide films by conversion of anodic films on magnesium alloy AZ31 and their corrosion protection. Appl Surf Sci, 2018, 456: 419–429

Berglund IS, Jacobs BY, Allen KD, et al. Peri-implant tissue response and biodegradation performance of a Mg-1.0Ca-0.5Sr alloy in rat tibia. Mater Sci Eng-C, 2016, 62: 79–85

Huehnerschulte TA, Angrisani N, Rittershaus D, et al. In vivo corrosion of two novel magnesium alloys ZEK100 and AX30 and their mechanical suitability as biodegradable implants. Materials, 2011, 4: 1144–1167

Yoshizawa S, Brown A, Barchowsky A, et al. Magnesium ion stimulation of bone marrow stromal cells enhances osteogenic activity, simulating the effect of magnesium alloy degradation. Acta Biomater, 2014, 10: 2834–2842

Hänzi AC, Gerber I, Schinhammer M, et al. On the in vitro and in vivo degradation performance and biological response of new biodegradable MgYZn alloys. Acta Biomater, 2010, 6: 1824–1833

Tian P, Peng F, Wang D, et al. Corrosion behavior and cytocompatibility of fluoride-incorporated plasma electrolytic oxidation coating on biodegradable AZ31 alloy. Regener Biomater, 2016, 4: 1–10

Peng F, Wang D, Zhang D, et al. PEO/Mg-Zn-Al LDH composite coating on Mg alloy as a Zn/Mg ion-release platform with multi-functions: Enhanced corrosion resistance, osteogenic, and antibacterial activities. ACS Biomater Sci Eng, 2018, 4: 4112–4121

Wang J, Qian S, Liu X, et al. M2 macrophages contribute to osteogenesis and angiogenesis on nanotubular TiO2 surfaces. J Mater Chem B, 2017, 5: 3364–3376

Lu T, Wen J, Qian S, et al. Enhanced osteointegration on tantalumimplanted polyetheretherketone surface with bone-like elastic modulus. Biomaterials, 2015, 51: 173–183

Jiang L, Zhang W, Wei L, et al. Early effects of parathyroid hormone on vascularized bone regeneration and implant osseointegration in aged rats. Biomaterials, 2018, 179: 15–28

Klotz K, Weistenhöfer W, Neff F, et al. The health effects of aluminum exposure. Deutsch Aerztebl Int, 2017, 114: 653–659

Lin S, Yang G, Jiang F, et al. A magnesium-enriched 3D culture system that mimics the bone development microenvironment for vascularized bone regeneration. Adv Sci, 2019, 6: 1900209

Wang J, Tang J, Zhang P, et al. Surface modification of magnesium alloys developed for bioabsorbable orthopedic implants: A general review. J Biomed Mater Res, 2012, 100B: 1691–1701

Li CY, Gao L, Fan XL, et al. In vitro degradation and cytocompatibility of a low temperature in-situ grown self-healing MgAl LDH coating on MAO-coated magnesium alloy AZ31. Bioact Mater, 2020, 5: 364–376

Peng F, Zhang D, Wang D, et al. Enhanced corrosion resistance and biocompatibility of magnesium alloy by hydroxyapatite/graphene oxide bilayer coating. Mater Lett, 2020, 264: 127322

Tian P, Liu X, Ding C. In vitro degradation behavior and cytocompatibility of biodegradable AZ31 alloy with PEO/HT composite coating. Colloids Surf B-Biointerfaces, 2015, 128: 44–54

Wei Z, Tian P, Liu X, et al. In vitro degradation, hemolysis, and cytocompatibility of PEO/PLLA composite coating on biodegradable AZ31 alloy. J Biomed Mater Res, 2015, 103: 342–354

Bowen PK, Drelich A, Drelich J, et al. Rates of in vivo (arterial) and in vitro biocorrosion for pure magnesium. J Biomed Mater Res, 2015, 103: 341–349

Hiromoto S, Inoue M, Taguchi T, et al. In vitro and in vivo biocompatibility and corrosion behaviour of a bioabsorbable magnesium alloy coated with octacalcium phosphate and hydroxyapatite. Acta Biomater, 2015, 11: 520–530

Zhao D, Witte F, Lu F, et al. Current status on clinical applications of magnesium-based orthopaedic implants: A review from clinical translational perspective. Biomaterials, 2017, 112: 287–302

Li Z, Gu X, Lou S, et al. The development of binary Mg-Ca alloys for use as biodegradable materials within bone. Biomaterials, 2008, 29: 1329–1344

Walker J, Shadanbaz S, Woodfield TBF, et al. Magnesium biomaterials for orthopedic application: A review from a biological perspective. J Biomed Mater Res, 2014, 102: 1316–1331

Angrisani N, Reifenrath J, Zimmermann F, et al. Biocompatibility and degradation of LAE442-based magnesium alloys after implantation of up to 3.5 years in a rabbit model. Acta Biomater, 2016, 44: 355–365

Acknowledgements

This work was supported by the National Natural Science Foundation of China (81901048, 81921002, 81620108006 and 31771044), Shanghai Committee of Science and Technology, China (18410760600), and the International Partnership Program of Chinese Academy of Sciences (GJHZ1850).

Author information

Authors and Affiliations

Contributions

Author contributions Jiang X, Liu X and Wang J conceived the concept of the study and provided funding support; Peng F and Wang D provided experimental materials and processing technology support; Peng F conducted the part of sample preparation and characterization experiments; Peng F and Wu X conducted the part of in vitro rBMSC experiments; Zheng A, Cao L, Yu C and Wang J conducted the in vivo experiments; Wang J and Peng F performed data analysis and drafted the manuscript; Jiang X, Liu X and Cao L reviewed the manuscript; Wang J, Jiang X, Peng F and Liu X integrated the suggestions of all authors and finished the paper.

Corresponding authors

Ethics declarations

Conflict of interest The authors declare that they have no conflict of interest.

Additional information

Jie Wang received her master degree of seven-year program in stomatology from Nanjing University in 2014 and PhD degree from Shanghai Jiao Tong University School of Medicine in 2017. Her research interests include tissue engineering and regenerative medicine, with a particular focus on the biodegradable materials.

Feng Peng received his bachelor degree from Central South University in 2014 and PhD degree from Shanghai Institute of Ceramics, Chinese Academy of Sciences in 2019. His current research interest focuses on biodegradable magnesium alloys for biomedical application.

Xuanyong Liu received his PhD degree in materials science and engineering from Shanghai Institute of Ceramics, Chinese Academy of Sciences, in 2002. His research interests lie in the following areas: nanosized and functionalized surface of biomedical Ti alloys, PEEK and biodegradable magnesium alloys, surface modification of biomaterials using plasma immersion ion implantation & deposition (PIII&D) technology, and plasma sprayed bioactive ceramic coatings.

Xinquan Jiang now serves as the Executive Dean of the College of Stomatology, Shanghai Jiao Tong University, Director of the Department of Prosthodontics of Shanghai Ninth People’s Hospital, Director of Shanghai Engineering and Research Center in the Universities for Advanced Dental Technology and Materials. His lab focuses on the research and application of the regeneration and repair of oral and maxillofacial bone tissues as well as expanding basic research into clinical practice.

Rights and permissions

About this article

Cite this article

Wang, J., Peng, F., Wu, X. et al. Biocompatibility and bone regeneration of PEO/Mg-Al LDH-coated pure Mg: an in vitro and in vivo study. Sci. China Mater. 64, 460–473 (2021). https://doi.org/10.1007/s40843-020-1392-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-020-1392-5