Abstract

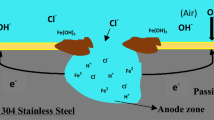

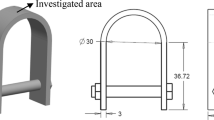

This study aims to examine the electrochemical corrosion behavior of a type (Forged) F304 stainless steel (SS) in the FeCl3 solution at 5 °C, 22 °C to 50 °C for the period of 24 h. The corrosion behavior was studied by using ASTM G48 which includes, weight loss and corrosion rate. The corrosion products were characterized with the help of EDX analysis. The specimen surfaces were observed by using scanning electron microscopy (SEM). In the distinctive FeCl3 solution, the material leads to the formation of several small pits that coalescence together to form cracks that appear at the surface and the bottom of the pit under different temperatures. The EDX analysis specifies the atomic percentage and at 50 °C, the characterized data represent fewer Cr species, and higher Cl− ions. These results indicated the lower corrosion resistance and the dissolution of chloride ions in abundance around the pit surface. It was found that the material degradation was faster at the pit bottom, and also more susceptible to new pits and cracks. Further, in practical amplification, the experimental results are useful to understand the material behavior at different temperatures. It is also helpful for the application of F304 SS such as gate valve disk.

Similar content being viewed by others

References

Ying Y, Li W, Cai L, Hou B (2008) Electrochemical and quantum chemical study of purines as corrosion inhibitors for mild steel in 1M HCl solution. Electrochim Acta 53:5953–5960

Kaneko M, Isaacs HS (2011) Effects of Mo and Cr on pitting corrosion resistance of austenitic stainless steels in Br and Cl solutions. J Antimicrob Chemother 20:1–6

Behbahani KM, Najafisayar P, Pakshir M (2016) Study of the intergranular corrosion of sensitized UNS S31803 stainless steel in transpassive region. J Mater Eng Perform 25:3418–3429

R.T. Hill, F.A. Ramirez, and A.L. Perez, B.A. Monty, Material Selection and Corrosion Control for Topside Process and Utility Piping and Equipment, NACE International*Corrosion 2012.

Xin SS, Li MC, Shen JN (2014) Effect of temperature and concentration ratio on pitting resistance of 316L stainless steel in seawater. Acta Metall Sin 50(3):373–378

Park JO, Matsch S, Böhni H (2002) Effects of temperature and chloride concentration on pit initiation and early pit growth of stainless steel. J Electrochem Soc 149(2):B34–B39

Dastgerdi AA, Brenna A, Ormellese M, Pedeferri M, Bolzoni F (2019) Experimental design to study the influence of temperature, pH, and chloride concentration on the pitting and crevice corrosion of UNS S30403 stainless steel. Corros Sci 159:108160

Pal S, Bhadauria SS, Kumar P (2019) Pitting corrosion behavior of F304 stainless steel under the exposure of ferric chloride solution. J Bio-and Tribo-Corrosion 5(4):91

Tsutsumi Y, Nishikata A, Tsuru T (2007) Pitting corrosion mechanism of Type 304 stainless steel under a droplet of chloride solutions. Corros Sci 49(3):1394–1407

J.J.M. Heselmans, J.W.H.van Duijn, Stainless Steel World 12 (2001): p. 21.

S. Shoji, N. Ohnaka, Boshoku Gijutsu (1989) Anticorrosion technology 38: p. 92.

Bayoumi FM, Ghanem WA (2005) Effect of nitrogen on the corrosion behavior of austenitic stainless steel in chloride solutions. Mater Lett 59(26):3311–3314

Waard CD, Lotz U, Milliams D (1991) Corrosion 47:976

Khajuria A, Akhtar M, Bedi R, Kumar R, Ghosh M, Das CR, Albert SK (2020) Microstructural investigations on simulated intercritical heat-affected zone of boron modified P91-steel. Mater Sci Technol 36(13):1407–1418

Khajuria, A., Bedi, R., & Kumar, R. (2019). Investigation of impression creep deformation behavior of boron-modified P91 steel by high-end characterization techniques. In Manufacturing Engineering (pp. 137–150). Springer, Singapore.

Khajuria A, Kumar R, Bedi R (2019) Effect of boron addition on creep strain during impression creep of P91 steel. J Mater Eng Perform 28(7):4128–4142

Akhtar, M., & Khajuria, A. (2020). Effects of prior austenite grain size on impression creep and microstructure in simulated heat affected zones of boron modified P91 steels. Materials Chemistry and Physics, 122847.

Akhtar, M., Khajuria, A., & Bedi, R. (2020). Effect of Re-normalizing and Re-tempering on Inter-critical Heat Affected Zone (S) of P91B Steel. In Manufacturing Engineering (pp. 255–270). Springer, Singapore.

Khajuria A, Akhtar M, Bedi R, Kumar R, Ghosh M, Das CR, Albert SK (2020) Influence of boron on microstructure and mechanical properties of Gleeble simulated heat-affected zone in P91 steel. Int J Press Vessels Pip 188:104246

Pal S, Khajuria A, Akhtar M (2018) Influence of aging on hardness and tool wear of artificially aged aluminium alloy 6061. IAETSD J Adv Res Appl Sci 5(2):477–481

Pal S, Khajuria A, Akhtar M (2018) Simulation and modelling of edge crack propagation of 2D-plate using Casca and Franc-2D. IAETSD J. Adv. Res. Appl. Sci. 5:439–446

Khajuria, A., Kumar, R., & Bedi, R. (2018). Characterizing creep behaviour of modified 9Cr1Mo steel by using small punch impression technique for thermal powerplants. Journal of Mechanical and Mechanics Engineering, 4.

Zhang Y, Luo H, Zhong Q, Yu H, Lv J (2019) Characterization of passive films formed on as-received and sensitized AISI 304 stainless steel. Chinese Journal of Mechanical Engineering 32(1):27

Acknowledgements

Authors would like to thanks the METT- BIO Laboratory and Dr. B R Ambedkar National Institute of Technology, Jalandhar, India for their support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pal, S., Bhadauria, S.S. & Kumar, P. Electrochemical Corrosion Behavior of Type F304 Stainless Steel in Different Temperatures. J Bio Tribo Corros 7, 43 (2021). https://doi.org/10.1007/s40735-021-00481-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00481-z