Abstract

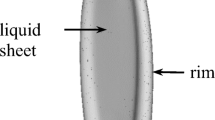

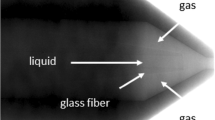

In this study, the behavior of liquid nitrogen jets and dual-like jet impingement of liquid nitrogen discharged from needle injectors were evaluated. Water has also been used to investigate the behavior of liquid jets and jet impingement at low Reynolds numbers. High-speed photography has been used to investigate various patterns formed in this interaction. The velocities of the liquid nitrogen jets varied from 12 to 34 m/s corresponding to Reynolds number from 50,000 to 136,000. By qualitatively comparing the photographs taken from the water jet impingement, the velocity range and Reynolds number corresponding to closed rim, periodic rim, open rim and fully developed sheet models were determined. In this study, the breakup model of liquid nitrogen jet impingement in a test chamber with a pressure of 2 bar and a temperature of 77 K is a fully developed and the surface of jets is completely wavy. The impingement of wavy jets creates impingement waves on the surface of the sheet. As the speed of the jets increases, the dimensions of the liquid sheet become smaller due to the formation of stronger impingement waves and the faster breakup of the liquid sheet. In addition to liquid nitrogen jets, saturated liquid nitrogen jets have also been studied. The impingement of two saturated liquid nitrogen jets with an angle of impingement of 60 degrees and standard atmospheric condition and low injector pressure causes the formation of a two-phase spray sheet in the form of a bell. As the injection pressure increases, the liquid phase in the jet increases and the spray angle of the jet impingement increases.

Similar content being viewed by others

References

Fajgenbaum R, Gonçalves R, Santos D (2016) Influence of fuel temperature on atomization parameters in a pressure-swirl atomizer from a port fuel injector by shadowgraphy technique. J Braz Soc Mech Sci Eng 38:1877–1892. https://doi.org/10.1007/s40430-015-0443-0

Silva RE, dos Santos LR, Alves A, Lacava PT (2017) Experimental assessment of a pressure swirl atomizer for ethanol operation on a small gas generator. J Braz Soc Mech Sci Eng 39:1909–1917. https://doi.org/10.1007/s40430-017-0732-x

Mohammadnejad S, Amani E, Hosseini R, Chitsaz I, Kamali A (2019) Effects of the swirl ratio and spray angle on the mixture stratification in a diesel–NG RCCI engine. J Braz Soc Mech Sci Eng 41:1–17. https://doi.org/10.1007/s40430-019-1736-5

Pedreira M, Dutra CL, Oliveira IS, Gonçalves FB, Rocha J, Rocco FAA (2019) Performance analysis of injectors for a hybrid propulsion system, J Braz. Soc Mech Sci Eng 41:1–10. https://doi.org/10.1007/s40430-018-1544-3

Heidman M F, Priem R J, Humphrey JC (1957) A study of sprays formed by two impinging jets. NACA Tech Note 3835

Dombrowski N, Hooper PC (1964) A study of the sprays formed by impinging jets in laminar and turbulent flow. Fluid Mech 18:392–398

Bremond N, Villermaux E (2006) Atomization by jet impact. Fluid Mech 549:273–306

Brinckman K W, Feldman G M, Hosangadi A (2015) Impinging fuel injector atomization and combustion modeling. 51th AIAA/SAE/ASEE/ joint propulsion conference, Orlando, America, pp1–12

Aggarwal A, Sanjay V, Kumar P, and Das A K (2016) Generation of a liquid sheet by an oblique impingement of interacting jets: a numerical investigation. Chemical engineering towards sustainable development, Chennai, India, pp 1–8

Zhang P, Wang B (2017) Effects of elevated ambient pressure on the disintegration of impinged sheets. Phys Fluids 29:1–17

Ruan C, Xing F, Huang Y, Xu L, Lu X (2017) A parametrical study of the breakup and atomization processof two impinging liquid jets. Atom Sprays 27:1025–1040

Xia Y, Khezzar L, Alshehhi M, Hardalupas Y (2018) Atomization of impinging opposed water jets interaction with an air jet. Exp Thermal Fluid Sci 93:11–22. https://doi.org/10.1016/j.expthermflusci.2017.12.010

Xia Y, Khezzar L, Bojanampati S, Molki A (2019) Breakup of the water sheet formed by two liquid impinging jets. Int J Chem Eng 2019:1–8

Saurabh A, Deshmukh D, Shubhankar N, Agarwal D (2020) Impingement atomization of carbopol gels. AIAA Propul Energy Forum 60(11):1–13

Tomac M (2020) Novel jet impingement atomization by synchronizing the sweeping motion of the fluidic oscillators. J Vis. https://doi.org/10.1007/s12650-020-00632-3

Vasantha kumar S K, Frederick R A (2020) Experimental investigation of spray characteristics for different geometrical misalignment cases of like doublet impinging injectors. AIAA Propul Energy Forum America, pp1–14

Zhang C, Zhang Z, Wu K, Xia X, Fan X (2021) Atomization of misaligned impinging liquid jets. Phys Fluids 33:1–15

Shen YB, Poulikakos D (1998) Impinging jet atomization at elevated and supercritical ambient temperature and pressure conditions. Experimental Heat Transfer 11:23–40

Mohan AM, Anand TNC, Ravikrishna RV (2018) Atomization patterns produced by viscous, like-on-like impinging liquid jets. Int Flow Visualization Image Proc 25:65–76

Timmerhaus K D, Flynn TM (1989) Cryogenic process engineering. First edition, plenum Press, New York

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH image to imagej: 25 years of image analysis. Nat Methods 9(7):671–675

Anderson WE, Ryan HM, Pal S, and Santoro R J (1993) Spray formation processes of impinging jets injectors. NACA Prop Eng Res 69–74.

Fox RW, McDonald AT, Pritchard PJ (2003) Introduction to fluid mechanics, 6th edn. John wiley, USA

Lemmon E W, I H Bell, Huber ML, McLinden ʻM O (2018) NIST Standard reference database 23: reference fluid thermodynamic and transport properties-REFPROPʼ, version 10.0, National Institute of standards and technology, standard reference data program, Gaithersburg

Dumouchel C (2008) On the experimental investigation on primary atomization of liquid streams. Exp Fluids 45:371–422. https://doi.org/10.1007/s00348-008-0526-0

Lefebvre H, McDonnell VG (2017) Atomization and sprays. 2nd edition, CRC Press, Boca Raton https://doi.org/10.1201/9781315120911

Chehroudi B, Cohn R, Talley D (2002) Cryogenic shear layers: experiments and phenomenological modeling of the initial growth rate under subcritical and supercritical conditions. Int J Heat Fluid Flow 23:554–563

Chehroudi B, Talley D, Coy E (2002) Visual characteristics initial growth rate of round cryogenic jets at subcritical and supercritical pressures. Physics of fluid 14:1–12

Huimin L (1981) Science and engineering of droplets. Noyes Publication Park Ridge, New Jersey

Li R, Ashgriz N (2006) Characteristics of liquid sheets formed by two impinging jets. Phys Fluids 28:1–13

Poulikakos D (1993) Determination of structure temperature and concentration of the near injector region of impinging jets using holographic techniques. Proceeding of the AFOSR contractors meeting

Lai W, Huang T, Jiang T (2005) Effect of fluid properties on the characteristics of impinging jet sprays. Atom Sprays 15:457–468

Gadgil H P (2007) Studies on impinging jet atomizer, master of science dissertation in aerospace engineering, department of aerospace engineering. Indian institute of science, Bangalove, India

Ryan HM, Anderson WE, Pal S, Santoro RJ (1995) Atomization characteristics of impinging liquid jets. J Propul Power 11:1–11

Funding

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Technical Editor: Erick Franklin.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Moosavian, D., Ghassemi, H. & Mostofizadeh, A. Experimental study of atomization of liquid nitrogen jet impingement. J Braz. Soc. Mech. Sci. Eng. 45, 302 (2023). https://doi.org/10.1007/s40430-023-04217-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04217-7