Abstract

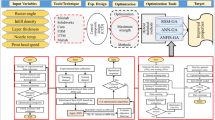

Glass multi-station bending machining (GMBM) is a high-precision and efficient glass processing technique for smartphone curved screen in 3C industry. In this paper, simulation model of the GMBM of smartphone curved screen was researched by using MSC Marc software. The stress relaxation and structural relaxation models of glass material were used in the numerical model to accurately predict the forming process of the glass component. The effects of process parameters of GMBM, namely heating rate (HR), holding time, bending temperature (BT), bending pressure and cooling rate (CR), on the product quality characteristics (residual stress and shape deviation) and energy efficiency were analyzed based on orthogonal experiments. It can be found that the BT, CR and HR have extremely important effects on product residual stress, shape deviation and energy efficiency. Furthermore, a multi-objective optimization method based on NSGA-III (a non-dominant sorting genetic algorithms based on reference points) was applied to efficiently solve the optimization problem between glass product quality and energy efficiency. The optimal parameter schemes with high quality and low energy efficiency were obtained by the Pareto front of multi-objective, and the average prediction errors of the numerical results by the optimized schemes are no more than 20% through confirm experiments. The optimized schemes improve the stability of the process of GMBM, which can deal with the challenge of green manufacturing.

Similar content being viewed by others

References

Blair G, Clarence C (1974) Method for molding glass lens. U.S. Patent. 3833347

Cha DH, Park HS, Hwang Y (2011) Experimental study of glass molding process and transcription characteristics of mold surface in molding of aspheric glass lenses. Opt Rev 18(2):241–246

Nieto D, Flores-Arias MT, O’Connor G, Gomez-Reino C (2010) Laser direct-write technique for fabricating microlens arrays on soda-lime glass with a Nd:YVO4 laser. Appl Opt 49(26):4979–4983

Yi AY, Jain A (2005) Compression molding of aspherical glass lenses—a combined experimental and numerical analysis. J Am Ceram Soc 88(3):579–586

Ananthasayanam B, Joseph PF, Joshi D (2012) Final shape of precision molded optics: part I—computational approach, material definitions and the effect of lens shape. J Therm Stress 35(6):550–578

Yan J, Zhou T, Masuda J (2009) Modeling high-temperature glass molding process by coupling heat transfer and viscous deformation analysis. Precis Eng 33(2):150–159

Jain A, Yi AY, Xie X (2006) Finite element modelling of stress relaxation in glass lens moulding using measured, temperature-dependent elastic modulus and viscosity data of glass. Model Simul Mater Sci 14(3):465–477

Zhou T, Yan J, Kuriyagawa T (2007) Evaluating the viscoelastic properties of glass above transition temperature for numerical modeling of lens molding process. Proc SPIE 6624:175–182

Zhou T, Yan J, Masuda J (2009) Investigation on the viscoelasticity of optical glass in ultraprecision lens molding process. J Mater Process Technol 209(9):4484–4489

Saotome Y, Imai K, Sawanobori N (2003) Microformability of optical glasses for precision molding. J Mater Process Technol 140(1–3):379–384

Jain A, Firestone GC, Yi AY (2005) Viscosity measurement by cylindrical compression for numerical modeling of precision lens molding process. J Am Ceram Soc 88(9):2409–2414

Jain A, Yi AY (2005) Numerical modeling of viscoelastic stress relaxation during glass lens forming process. J Am Ceram Soc 88(3):530–535

Jain A, Yi AY (2006) Finite element modeling of structural relaxation during annealing of a precision-molded glass lens. J Manuf Sci Eng 128(3):683–690

Zhou J, Shi T, Hu Y (2013) Numerical simulation in compression molding of glass lens. In: CASE, IEEE, pp 669–674

Nielsen JH, Olesen JF, Poulsen PN (2010) Finite element implementation of a glass tempering model in three dimensions. Comput Struct 88(17–18):963–972

Ananthasayanam B (2008) Computational modeling of precision molding of aspheric glass optics. Mechanical Engineering, Doctorate of Philosophy, Clemson University

Zhou T, Yan J, Masuda J (2011) Investigation on shape transferability in ultraprecision glass molding press for microgrooves. Precis Eng 35(2):214–220

Zhou TF, Yan JW, Masda J (2009) Investigation on ultraprecision molding process for microgrooves on glass plate. In: the 3rd international conference of Asian society for precision engineering and nanotechnology, kitakyushu, Japan, pp 65–68

Jain A (2006) Experimental study and numerical anslysis of compression molding process for manufacturing precision aspherical glass lenses. The Ohio State University, Columbus

Anurag Jain (2004) Numerical simulation of compression molding of aspherical glass lenses. AIP 712:239–244

Aronen A (2012) Modelling of deformations and stresses in glass tempering. Tampereen teknillinen yliopisto. Julkaisu-Tampere University of Technology. Publication, p 1036

Aronen A, Karvinen R (2018) Effect of glass temperature before cooling and cooling rate on residual stresses in tempering. Glass Struct Eng 3(1):3–15

Schneider J, Hilcken J, Aronen A (2016) Stress relaxation in tempered glass caused by heat soak testing. Eng Struct 122:42–49

Scherer GW (1986) Relaxation in glass and composites. Wiley, New York

Kurkjian C (1963) Relaxation of torsional stress in transformation range of soda-lime-silica glass. Phys Chem Glasses 4(4):128–36

Duffrene L, Gy R (1997) Viscoelastic constants of a soda-lime-silica glass. J Non Cryst Solids 211(1):30–38

Hoque A, Fischer CE, Wu WT (2001) Simulation of glass pressing process using 3-dimensional large deformation finite element software. Scientific Forming Technologies Corporation, Columbus, pp 156–163

Druma C, Alam MK, Druma AM (2004) Finite element analysis of TV panel glass during cooling. Mater Manuf Process 19(6):1171–1187

Zhao D, Liu P, He L (2016) Numerical and experimental investigation of the heating process of glass thermal slumping. J Opt Soc Korea 20(2):314–320

Soules TF, Busbey RF, Rekhson SM (1987) Finite-element calculation of stresses in glass parts undergoing viscous relaxation. J Am Ceram Soc 70(2):90–95

Narayanaswamy OS (1971) A model of structural relaxation in glass. J Am Ceram Soc 54(10):491–498

Richet P, Bottinga Y, Tequi C (1984) Heat capacity of sodium silicate liquids. J Am Ceram Soc 67(1):6–8

Mann D, Field RE, Viskanta R (1992) Determination of specific heat and true thermal conductivity of glass from dynamic temperature data. Waerme-und Stoffuebertragung 27(4):225–231

Sharp DE, Ginther LB (2010) Effect of composition and temperature on the specific heat of glass. J Am Ceram Soc 34(9):260–271

Storck K, Karlsson M, Loyd D (1994) Analysis of the blank mould-a transient heat transfer problem in glass, forming. WIT Trans Eng Sci 5. https://doi.org/10.2495/HT940221

Su CH (2011) Mold shape compensation and residual stress analysis in molding process of aspherical glass lenes. National chiao Tung University, Hsinchu City

Yi AY, Tao B, Klocke F (2011) Residual stresses in glass after molding and its influence on optical properties. Procedia Eng 19(1):402–406

Pourmoghaddam N, Schneider J (2018) Finite-element analysis of the residual stresses in tempered glass plates with holes or cut-outs. Glass Struct Eng 3(1):17–37

Tao B, He P, Shen L (2014) Quantitatively measurement and analysis of residual stresses in molded aspherical glass lenses. Int J Adv Manuf Technol 74(9–12):1167–1174

He W, He S, Du J (2019) Fiber orientations effect on process performance for wire cut electrical discharge machining (WEDM) of 2D C/SiC composite. Int J Adv Manuf Technol 102(1–4):507–518

Dumbhare PA, Dubey S, Deshpande YV (2018) Modelling and multi-objective optimization of surface roughness and kerf taper angle in abrasive water jet machining of steel. J Braz Soc Mech Sci Eng 40(5):259

Harmesh K, Alakesh M, Rajesh K (2018) Modeling and desirability approach-based multi-response optimization of WEDM parameters in machining of aluminum metal matrix composite. J Braz Soc Mech Sci Eng 40(9):458

Bouacha K, Terrab A (2016) Hard turning behavior improvement using NSGA-II and PSO-NN hybrid model. Int J Adv Manuf Technol 86(9–12):1–20

Chunrong W, Jing Z, Erdong X (2018) Multi-objective optimal design of a novel multi-function rescue attachment based on improved NSGA-II. J Braz Soc Mech Sci Eng 40(7):344

Darvish Damavandi M, Safikhani H, Yahyaabadi M (2017) Multi-objective optimization of asymmetric v-shaped ribs in a cooling channel using CFD, artificial neural networks and genetic algorithms. J Braz Soc Mech Sci Eng 39(6):2319–2329

Ming W, Zhang Z (2019) Comparative study of energy efficiency and environmental impact in magnetic field assisted and conventional electrical discharge machining. J Clean Prod 214:12–28

Acknowledgements

This research is supported by the Natural Science Foundation of Guangdong Province (2018A030313679) and the Natural Science Foundation of Henan Province (Grant No. 182300410215). In addition, this research is also supported by Natural Science Foundation (Grant No. 11602230), by Local Innovative and Research Team Project of Guangdong Pearl River Talents Program (Grant No. 2017BT01G167) and by the development program (2017B030314146) of Guangdong Provincial Key Laboratory.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Zilda de Castro Silveira, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, W., Chen, Z., Ming, W. et al. Multi-objective optimization of glass multi-station bending machining for smartphone curved screen. J Braz. Soc. Mech. Sci. Eng. 41, 476 (2019). https://doi.org/10.1007/s40430-019-1985-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-1985-3