Abstract

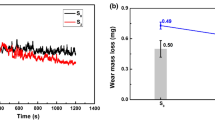

Zn-10 Mg composite with a core–shell structure was prepared by spark plasma sintering (SPS) technology, and a systematic study of the microstructure and properties has been conducted for different sintering times. The shell layer dominated by the hard MgZn2 phase thickens with the increase in sintering time, which has a positive effect on the mechanical and degradation properties of the material. The sample sintered for 20 min (T-20) has the best mechanical properties, with a compressive strength of 226 MPa and a compression rate of 6.5%. The corrosion resistance of samples increases as the sintering time prolongs, while the hydrogen evolution volume and pH value decrease in the immersion experiment. Furthermore, the increase in the shell thickness significantly reduces the corrosion rate, which is attributed to the weakening of the galvanic corrosion reaction between the Mg core and the MgZn2 shell. Therefore, composite with unique core–shell structure provides an advanced design idea for degradable biomaterials, and a reasonable control of sintering time can provide the optimal design strategy.

Similar content being viewed by others

References

X. Wang, X. Shao, T. Dai, F. Xu, J.G. Zhou, G. Qu, L. Tian, B. Liu, Y. Liu, Acta Biomater. 92, 351 (2019)

J.L. Wang, J.K. Xu, C. Hopkins, D.H.K. Chow, L. Qin, Adv. Sci. 7, 1902443 (2020)

N. Li, Y. Zheng, J. Mater. Sci. Technol. 29, 489 (2013)

W. Jahnen Dechent, M. Ketteler, Clin. Kidney J. 5, i3 (2012)

W. Pachla, S. Przybysz, A. Jarzebska, M. Bieda, K. Sztwiertnia, M. Kulczyk, J. Skiba, Bioact. Mater. 6, 26 (2021)

D. Vojtěch, J. Kubásek, J. Šerák, P. Novák, Acta Biomater. 7, 3515 (2011)

J. Kubásek, D. Vojtěch, E. Jablonská, I. Pospíšilová, J. Lipov, T. Ruml, Mater. Sci. Eng. C 58, 24 (2016)

E. Jablonská, D. Vojtěch, M. Fousová, J. Kubásek, J. Lipov, J. Fojt, T. Ruml, Mater. Sci. Eng. C 68, 198 (2016)

C. Shen, X. Liu, B. Fan, P. Lan, F. Zhou, X. Li, H. Wang, X. Xiao, L. Li, S. Zhao, Z. Guo, Z. Pu, Y. Zheng, RSC Adv. 6, 86410 (2016)

A. Jarzębska, M. Bieda, J. Kawałko, Ł Rogal, P. Koprowski, K. Sztwiertnia, W. Pachla, M. Kulczyk, Mater. Lett. 211, 58 (2018)

H.F. Li, X.H. Xie, Y.F. Zheng, Y. Cong, F.Y. Zhou, K.J. Qiu, X. Wang, S.H. Chen, L. Huang, L. Tian, L. Qin, Sci. Rep. 5, 10719 (2015)

H. Li, H. Yang, Y. Zheng, F. Zhou, K. Qiu, X. Wang, Mater. Des. 83, 95 (2015)

H. Yang, X. Qu, W. Lin, D. Chen, D. Zhu, K. Dai, Y. Zheng, A.C.S. Biomater, Sci. Eng. 5, 453 (2019)

J. Kubásek, D. Dvorský, J. Čapek, J. Pinc, D. Vojtěch, Materials 12, 3930 (2019)

Z. Cui, M. Luo, Y. Zhang, D. Gong, W. Wang, J. Wang, Mater. Lett. 279, 128525 (2020)

T. Kokubo, H. Takadama, Biomaterials 27, 2907 (2006)

E. McCafferty, Corros. Sci. 12, 3202 (2005)

ASTM G31–72 (2004), Standard Practice for Laboratory Immersion Corrosion Testing of Metals (ASTM International, West Conshohocken, 2004). www.astm.org. https://doi.org/10.1520/g0031-72r04

Y. Meng, G. Jiang, X. Ju, J. Hao, Mater. Charact. 129, 336 (2017)

B. Rashkova, W. Prantl, R. Görgl, J. Keckes, S. Cohen, M. Bamberger, G. Dehm, Mater. Sci. Eng. A 494, 158 (2008)

K. Yan, J. Bai, H. Liu, Z.Y. Jin, J. Magnes. Alloy. 5, 336 (2017)

J. Yang, J.L. Wang, Y.M. Wu, L.M. Wang, H.J. Zhang, Mater. Sci. Eng. A 460, 296 (2007)

V. Mamedov, Powder Metall. 45, 322 (2002)

K. Rezwan, Q.Z. Chen, J.J. Blaker, A.R. Boccaccini, Biomaterials 27, 3413 (2006)

H. Shao, Y. Huang, Y. Liu, Z. Xiao, Solid State Commun. 343, 114644 (2022)

X.N. Gu, Y.F. Zheng, Front. Mater. Sci. China 4, 111 (2010)

H.Y. Niu, F.F. Cao, K.K. Deng, K.B. Nie, J.W. Kang, H.W. Wang, Acta Metall. Sin. -Engl. Lett. 33, 362 (2020)

Y. Yan, H. Cao, Y. Kang, K. Yu, T. Xiao, J. Luo, Y. Deng, H. Fang, H. Xiong, Y. Dai, J. Alloys Compd. 693, 1277 (2017)

D. Noviana, D. Paramitha, M.F. Ulum, H. Hermawan, J. Orthop. Translat. 5, 9 (2016)

L.A. Schneider, A. Korber, S. Grabbe, J. Dissemond, Arch. Dermatol. Res. 298, 413 (2007)

Y. Shen, W. Liu, K. Lin, H. Pan, B.W. Darvell, S. Peng, C. Wen, L. Deng, W.W. Lu, J. Chang, Langmuir 27, 2701 (2011)

W.D. Mueller, M. Lucia Nascimento, M.F. Lorenzo de Mele, Acta Biomater. 6, 1749 (2010)

Y. Liu, X. Liu, Z. Zhang, N. Farrell, D. Chen, Y. Zheng, Corros. Sci. 161, 108185 (2019)

F. Rosalbino, E. Angelini, D. Macciò, A. Saccone, S. Delfino, Electrochim. Acta 54, 1204 (2009)

J.W. Lee, B.R. Park, S.Y. Oh, D.W. Yun, J.K. Hwang, M.S. Oh, S.J. Kim, Corros. Sci. 160, 108170 (2019)

Acknowledgements

The work was supported by the Natural Science Research General Program of Shanxi Province, China (No. 202103021224048), and the Shanxi Zhejiang University New Materials and Chemical Research Institute Scientific Research Project (No. 2022SX-TD025).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cui, Z., Zhou, L., Hao, X. et al. Effect of Sintering Time on the Mechanical and Corrosion Behavior of Zn–Mg Composites with a Core–Shell Structure Prepared by SPS. Acta Metall. Sin. (Engl. Lett.) 36, 1305–1316 (2023). https://doi.org/10.1007/s40195-023-01548-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-023-01548-1