Abstract

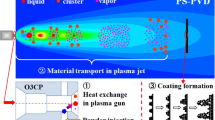

The use of plasma-enhanced chemical vapor deposition (PECVD) has drastically increased the development of 3D-NAND fabrication. We investigated a potential alternative method to replace the usage of NF3 in ACL deposition chamber cleaning with reasonable cleaning efficiency. Perfluoro-compounds (PFCs) have been listed as global warming gases, and NF3, which has 17,200 of 100 years GWP, is expected to be listed in a few years; thus, its usage for PECVD chamber cleaning in the semiconductor and display manufacturing industries may have restricted in the near future. To understand the plasma-cleaning phenomenon inside the PECVD chamber, we monitored the in situ plasma process using optical emission spectroscopy (OES) and quadrupole mass spectroscopy (QMS). The cleaning mechanism was revealed through the chemical species in the plasma using OES, and the presence of harmful gases in the exhaust stage was confirmed using QMS. O2, N2, and NH3 were selected as gases that could replace NF3, and the individual gases, as well as gas mixtures, were analyzed. A mixture of 20% N2 in O2 showed the highest film removal rate in ACL deposition chamber cleaning, and the gas with low GWP was released. Through this study, we propose an eco-friendly chamber cleaning method that can replace the existing method that causes global warming problems.

Similar content being viewed by others

References

C.C. Lai, Y.H. Chang, H.J. Chien, M.C. Lu, Hard mask and lithographic capabilities improvement by amorphous carbon step coverage optimization in high aspect ratio device pattern. Vacuum 153, 267 (2018). https://doi.org/10.1016/j.vacuum.2018.04.005

S.J. Park, D. Kim, S. Lee, Y. Ha, M. Lim, K. Kim, Diamond-like amorphous carbon layer film by an inductively coupled plasma system for next generation etching hard mask. Thin Solid Films 663, 21 (2018). https://doi.org/10.1016/j.tsf.2018.08.007

S. Kwon, Y. Park, W. Ban, C. Youn, S. Lee, J. Yang, D. Jung, T. Choi, Effect of plasma power on properties of hydrogenated amorphous silicon carbide hardmask films deposited by PECVD. Vacuum 174, 109187 (2020). https://doi.org/10.1016/j.vacuum.2020.109187

G. Lee, D.K. Sohn, S.H. Seok, H.S. Ko, The effect of hole density variation in the PECVD reactor showerhead on the deposition of amorphous carbon layer. Vacuum 163, 37 (2019). https://doi.org/10.1016/j.vacuum.2019.02.009

D. Kim, T. Kim, S.H. Park, S.K. Lim, H. Lee, T. Kim, S. Kang, Characterization of particle generated during plasma-enhanced chemical vapor deposition on amorphous carbon layer using particle beam mass spectrometer. J. Vac. Sci. Technol. A 36, 21506 (2018). https://doi.org/10.1116/1.5000087

A. Masuda, Y. Ishibashi, K. Uchida, K. Kamesaki, A. Izumi, H. Matsumura, In situ chamber cleaning using atomic H in catalytic-CVD apparatus for mass production of a-Si: H solar cells. Sol. Energy Mater. Sol. Cells 74, 373 (2002). https://doi.org/10.1016/S0927-0248(02)00130-7

S. Xu, Z. Sun, X. Qian, J. Holland, D. Podlesnik, Characteristics and mechanism of etch process sensitivity to chamber surface condition. J. Vac. Sci. Technol. B 19, 166 (2001). https://doi.org/10.1116/1.1330266

G. Cunge, B. Pelissier, O. Joubert, R. Ramos, C. Maurice, New chamber walls conditioning and cleaning strategies to improve the stability of plasma processes. Plasma Source Sci. Technol. 14, 599 (2005). https://doi.org/10.1088/0963-0252/14/3/025

A. Drenik, A. Vesel, M. Mozetič, Controlled carbon deposit removal by oxygen radicals. J. Nucl. Mater. 893, 386–388 (2009). https://doi.org/10.1016/j.jnucmat.2008.12.218

S.P. Gangoli, A.D. Johnson, A.A. Fridman, R.V. Pearce, A.F. Gutsol, A. Dolgopolsky, Production and transport chemistry of atomic fluorine in remote plasma source and cylindrical reaction chamber. J. Phys. D 40, 5140 (2007). https://doi.org/10.1088/0022-3727/40/17/020

J. Boudaden, S. Altmannshofer, R. Wieland, M. Pittroff, I. Eisele, An approach to reduce greenhouse gases in the semiconductor industry using F2 dissociated in plasma for CVD chamber cleaning. Appl. Sci. 8, 846 (2018). https://doi.org/10.3390/app8060846

S. Raoux, T. Tanaka, M. Bhan, H. Ponnekanti, M. Seamons, T. Deacon, L.Q. Xia, F. Pham, D. Silvetti, D. Cheung, K. Fairbairn, A. Jonhson, R. Pearce, J. Langan, Remote microwave plasma source for cleaning chemical vapor deposition chambers: technology for reducing global warming gas emissions. J. Vac. Sci. Technol. B 17, 477 (1999). https://doi.org/10.1116/1.590580

C.H. Oh, N. Lee, J.H. Kim, G.Y. Yeom, S.S. Yoon, T.K. Kwon, Increase of cleaning rate and reduction in global warming effect during C4F8O/O2 remote plasma cleaning of silicon nitride by adding NO and N2O. Thin Solid Films 435, 264 (2003). https://doi.org/10.1016/S0040-6090(03)00397-3

S. Huang, V. Volynets, J.R. Hamilton, S.K. Nam, I. Song, S. Lu, J. Tennyson, M.J. Kushner, Downstream etching of silicon nitride using continuous-wave and pulsed remote plasma sources sustained in Ar/NF3/O2 mixtures. J. Vac. Sci. Technol. A 36, 021305 (2018). https://doi.org/10.1116/1.5019673

W. Tsai, Environmental and health risk analysis of nitrogen trifluoride (NF3), a toxic and potent greenhouse gas. J. Hazard. Mater. 159, 257 (2008). https://doi.org/10.1016/j.jhazmat.2008.02.023

K.P. Kim, W.S. Song, M.K. Park, S.J. Hong, Surface analysis of amorphous carbon thin film for etch hard mask. J. Nanosci. Nanotechnol. 21, 2032 (2021). https://doi.org/10.1166/jnn.2021.18919

X. Li, X. Hua, L. Ling, G.S. Oehrlein, E. Karwacki, B. Ji, Surface chemical changes of aluminum during NF3-based plasma processing used for in-situ chamber cleaning. J. Vac. Sci. Technol. A 22, 158 (2004). https://doi.org/10.1116/1.1633566

K. Yang, S. Park, G. Yeom, Low global warming potential alternative gases for plasma chamber cleaning. Sci. Adv. Mater. 8, 2253 (2016). https://doi.org/10.1166/sam.2016.2885

G. Kang, S. An, K. Kim, S. Hong, An in situ monitoring method for PECVD process equipment condition. Plasma Sci. Technol. 21, 064003 (2019). https://doi.org/10.1088/2058-6272/aafb2b

M.H. Jeon, J.W. Park, D.H. Yun, K.N. Kim, G.Y. Yeom, Etch properties of amorphous carbon material using RF pulsing in the O2/N2/CHF3 plasma. J. Nanosci. Nanotechnol. 15, 8577 (2015). https://doi.org/10.1166/jnn.2015.11489

F. Anooshehpour, S. Turgeon, M. Cloutier, D. Mantovani, G. Laroche, Optical emission spectroscopy as a process-monitoring tool in plasma enhanced chemical vapor deposition of amorphous carbon coatings-multivariate statistical modelling. Thin Solid Films 649, 106 (2018). https://doi.org/10.1016/j.tsf.2018.01.029

G. Garcia-Cosio, H. Martinez, M. Calixto-Rodriguez, A. Gomez, DC discharge experiment in an Ar/N2/CO2 ternary mixture: a laboratory simulation of the Martian ionosphere’s plasma environment. J. Quant. Spectrosc. Radiat. Transf. 112, 2787 (2011). https://doi.org/10.1016/j.jqsrt.2011.09.008

R. Jani, J.S. Kim, M.K. Jacoby, S. Rajendran, S. Kashibhatla, in Proceedings of the 30th SEMI/ASMC (Saratoga Springs, NY, May 6–9, 2019). https://doi.org/10.1109/ASMC.2019.8791768

D. Xiang, H. Xia, W. Yang, P. Mou, Parametric study and residual gas analysis of large-area silicon-nitride thin-film deposition by plasma-enhanced chemical vapor deposition. Vacuum 165, 172 (2019). https://doi.org/10.1016/j.vacuum.2019.04.017

K.B.K. Teo, M. Chhowalla, G.A.J. Amaratunga, W.I. Milne, D.G. Hasko, G. Porio, P. Laganeux, F. Wyczisk, D. Pribat, Uniform patterned growth of carbon nanotubes without surface carbon. Appl. Phys. Lett. 79, 1534 (2001). https://doi.org/10.1063/1.1400085

Acknowledgements

This work was supported by Korea Evaluation Institute of Industrial Technology (GID: K_G012001079801). We are grateful to Mr. Yoo Young Lee and Bio Lim in R&D Center at TES, Korea, for their technical discussion on ACL deposition.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

An, SR., Choi, J.E. & Hong, S.J. In-situ process monitoring for eco-friendly chemical vapor deposition chamber cleaning. J. Korean Phys. Soc. 79, 1027–1036 (2021). https://doi.org/10.1007/s40042-021-00307-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40042-021-00307-8