Abstract

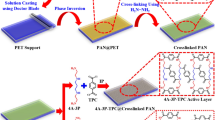

It is necessary to recover dimethyl sulfoxide (DMSO) from pharmaceutical organic wastewater. In recent years, organic solvent nanofiltration (OSN), as an important means of recovering organic solvents, is being studied and paid attention constantly. Here, we prepared a solvent-resistant composite nanofiltration membrane with stable performance for the recovery of DMSO solvent using orcinol (OL), a natural alkyl resorcinol compound to synthetize a thin-film composite polyarylester membrane with trimesoyl chloride (TMC) by interfacial polymerization (IP) on the polyetherimide (PEI) substrate crosslinked by ethylenediamine (EDA). The results of chemical characterization such as X-ray photoelectron spectroscopy (XPS) and attenuated total reflection fluorescence transform infrared spectroscopy (ATR-FTIR) show that interfacial polymerization occurs between TMC and orcinol on the surface of PEI and forms polyarylester top-layer. The rejection of crystal violet (CV, 407.99 g/mol) in DMSO takes place by 91%, and the maximum permeance is about 3.1 L.m−2.h−1.bar−1. To further improve selectivity of membrane, microwave heating was adopted as a strengthening method of interfacial polymerization. The results illustrate that the microwave heating can significantly increase the rejection of OL-TMC membrane. The optimized membrane shows stable solvent resistance in DMSO with a rejection of 98% for CV and the permeance of 1.8 L.m−2.h−1.bar−1 and a rejection of 81% for clindamycin phosphate (CLP) with the permeance of 1.9 L.m−2.h−1.bar−1. This study not only opens up an interesting research field for more natural polyphenols as solvent-resistant nanofiltration membrane materials, but also indicates that microwave-assisted heating can be used as an important means during IP process to strengthen the properties of OSN membranes.

Similar content being viewed by others

References

Srinivasa S (1964) Separation of hydrocarbon liquids by flow under pressure through porous membranes. Nature 203:1348–1349

Ryan PL, David SS (2017) From water to organics in membrane separations. Nat Mater 16:276–279

David SS, Ryan PL (2016) Seven chemical separations to change the world. Nature 532:435

Patrizia M, Maria FJS, Gyorgy S, Andrew GL (2014) Molecular separation with organic solvent nanofiltration: a critical review. Chem Rev 114:10735–10806

Feng Y, Weber M, Maletzko C, Chung TS (2019) Fabrication of organic solvent nanofiltration membranes via facile bioinspired one-step modification. Chem Eng Sci 198:74–84

Tham HM, Japip S, Hua D, Chung TS (2018) Green layer-by-layer method for the preparation of polyacrylonitrile-supported zinc benzene-1,4-dicarboxylic acid membranes. Chemsuschem 11:2612–2619

Wang Q, Wei X, Wang GR, Lu TD, Shi Q, Sun SP (2021) Inner-selective coordination nanofiltration hollow fiber membranes from assist-pressure modified substrate. J Membr Sci 626:119186

Xu S, Wang ZY, Li S, Tian L, Su B (2020) Fabrication of polyimide-based hollow fiber membrane by synergetic covalent-crosslinking strategy for organic solvent nanofiltration (OSN) application. Sep Purif Technol 241:116751

Liang Y, Li C, Li S, Su B, Hu MZ, Gao X, Gao C (2020) Graphene quantum dots (GQDs)-polyethyleneimine as interlayer for the fabrication of high performance organic solvent nanofiltration (OSN) membranes. Chem Eng J 380:122462

Zeng G, He Y, Zhan Y, Zhang L, Pan Y, Zhang C, Yu Z (2016) Novel polyvinylidene fluoride nanofiltration membrane blended with functionalized halloysite nanotubes for dye and heavy metal ions removal. J Hazard Mater 317:60–72

Zhang Y, Sun H, Sadam H, Liu Y, Shao L (2019) Supramolecular chemistry assisted construction of ultra-stable solvent-resistant membranes for angstrom-sized molecular separation. Chem Eng J 371:535–543

Li Y, Wong E, Volodine A, Haesendonck CV, Zhang K, Bruggen B (2019) Nanofibrous hydrogel composite membranes with ultrafast transport performance for molecular separation in organic solvents. J Mate Chem A 7:19269–19279

Natalia GD, Finn PM, Yurii KG (2020) Recent progress and future prospects in development of advanced materials for nanofiltration. Mater Today Commun 23:100888

Scharzec B, Holtkötter J, Bianga J, Dreimann JM, Vogt D, Skiborowski M (2020) Conceptual study of co-product separation from catalyst-rich recycle streams in thermomorphic multiphase systems by OSN. Chem Eng Res Des 157:65–76

Adam MR, Othman MHD, Kadir SHSA, Elma M, Kurniawan TA, Ismail AF, Puteh MH, Mustafa A, Rahman MA, Jaafar J, Abdullah H (2021) Ammonia removal by adsorptive clinoptilolite ceramic membrane: effect of dosage, isothermal behavior and regeneration process. Korean J Chem Eng 38:807–815

Wang Y, Gu J, Zhou A, Kong A, Almijbilee MMA, Zheng X, Zhang J, Li W (2020) Poly[acrylate-co-amide] network composite via photopolymerization for organic solvent nanofiltration separation. Sep Purif Technol 246:116855

Gao ZF, Shi GM, Cui Y, Chung TS (2018) Organic solvent nanofiltration (OSN) membranes made from plasma grafting of polyethylene glycol on cross-linked polyimide ultrafiltration substrates. J Membr Sci 565:169–178

Maria FJS, Song Q, Jelfs KE, Munoz-Ibanez M, Andrew GL (2016) Polymer nanofilms with enhanced microporosity by interfacial polymerization. Nat Mater 15:760–767

Abdellah MH, Pérez-Manríquez L, Puspasari T, Scholes CA, Kentish SE, Peinemann KV (2018) A catechin/cellulose composite membrane for organic solvent nanofiltration. J Membr Sci 567:139–145

Almijbilee MMA, Wu X, Zhou A, Zheng X, Cao X, Li W (2020) Polyetheramide organic solvent nanofiltration membrane prepared via an interfacial assembly and polymerization procedure. Sep Purif Technol 234:116033

Xu YC, Cheng XQ, Long J, Shao L (2016) A novel monoamine modification strategy toward high-performance organic solvent nanofiltration (OSN) membrane for sustainable molecular separations. J Membr Sci 497:77–89

Hai Y, Zhang J, Shi C, Zhou A, Bian C, Li W (2016) Thin film composite nanofiltration membrane prepared by the interfacial polymerization of 1,2,4,5-benzene tetracarbonyl chloride on the mixed amines cross-linked poly(ether imide) support. J Membr Sci 520:19–28

Zhou A, Shi C, He X, Fu Y, Anjum AW, Zhang J, Li W (2018) Polyarylester nanofiltration membrane prepared from monomers of vanillic alcohol and trimesoyl chloride. Sep Purif Technol 193:58–68

Aerts S, Vanhulsel A, Buekenhoudt A, Weyten H, Kuypers S, Chen H, Bryjak M, Gevers LEM, Vankelecom IFJ, Jacobs PA (2006) Plasma-treated PDMS-membranes in solvent resistant nanofiltration: characterization and study of transport mechanism. J Membr Sci 275:212–219

He X, Zhou A, Shi C, Zhang J, Li W (2018) Solvent resistant nanofiltration membranes using EDA-XDA co-crosslinked poly(ether imide). Sep Purif Technol 206:247–255

Singh S, Khulbe KC, Matsuura T, Ramamurthy P (1998) Membrane characterization by solute transport and atomic force microscopy. J Membr Sci 142:111–127

Michaels AS (1980) Analysis and prediction of sieving curves for ultrafiltration membranes: a universal correlation. Sep Purif Technol 15:1305–1322

Li W, Bian C, Fu C, Zhou A, Shi C, Zhang J (2016) A poly(amide-co-ester) nanofiltration membrane using monomers of glucose and trimesoyl chloride. J Membr Sci 504:185–195

Yang X, Jiang X, Huang Y, Guo Z, Shao L (2017) Building nanoporous metal–organic frameworks “armor” on fibers for high-performance composite materials. ACS Appl Mater Interfaces 9:5590

Wang Z, Yang X, Cheng Z, Liu Y, Shao L, Jiang L (2017) Simply realizing “water diode” Janus membranes for multifunctional smart applications. Mater Horiz 4:701–708

Ye D, Zhang M, Gan L, Li Q, Zhang X (2013) The influence of hydrogen peroxide initiator concentration on the structure of eucalyptus lignosulfonate. Int J Bio Macromol 60:77–82

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Hu J, Xiao R, Shen D, Zhang H (2013) Structural analysis of lignin residue from black liquor and its thermal performance in thermogravimetric-Fourier transform infrared spectroscopy. Bioresour Technol 128:633–639

Lin SY, Dence CW (1992) Methods in lignin chemistry. Springer-Verlag, New York

Haensel T, Comouth A, Lorenz P, Ahmed SIU, Krischok S, Zydziak N, Kauffmann A, Schaefer JA (2009) Pyrolysis of cellulose and lignin. Appl Surf Sci 255:8183–8189

Roy S, Yue CY, Venkatraman SS, Ma LL (2011) Low-temperature (below Tg) thermal bonding of COC microfluidic devices using UV photografted HEMA-modified substrates: high strength, stable hydrophilic, biocompatible surfaces. J Mater Chem 21:15031–15040

Albrecht W, Seifert B, Weigel T, Schossig M, Holländer A, Groth T, Hilke R (2003) Amination of poly(ether imide) membranes using di- and multivalent amines. Macromol Chem Phys 204:510–521

Huang BQ, Tang YJ, Zeng ZX, Xu ZL (2020) Microwave heating assistant preparation of high permselectivity polypiperazine-amide nanofiltration membrane during the interfacial polymerization process with low monomer concentration. J Membr Sci 596:117718

Li N, Wang Z, Wang M, Gao M, Wang J (2021) Swelling-controlled positioning of nanofillers through a polyamide layer in thin-film nanocomposite membranes for CO2 separation. J Membr Sci 624:119095

Zhang Z, Kang G, Yu H, Jin Y, Cao Y (2019) Fabrication of a highly permeable composite nanofiltration membrane via interfacial polymerization by adding a novel acyl chloride monomer with an anhydride group. J Membr Sci 570–571:403–409

Zhu CY, Liu C, Yang J, Guo BB, Li HN, Xu ZK (2021) Polyamide nanofilms with linearly-tunable thickness for high performance nanofiltration. J Membr Sci 627:119142

Bera A, Trivedi JS, Kumar SB, Chandel AKS, Haldar S, Jewrajka SK (2018) Anti-organic fouling and anti-biofouling poly(piperazineamide) thin film nanocomposite membranes for low pressure removal of heavy metal ions. J Hazard Mater 343:86–97

Liu Y, Li S, Zhang J, Wang Y, Han Z, Ren L (2014) Fabrication of biomimetic superhydrophobic surface with controlled adhesion by electrodeposition. Chem Eng J 248:440–447

Bastin M, Hendrix K, Vankelecom I (2017) Solvent resistant nanofiltration for acetonitrile based feeds: a membrane screening. J Membr Sci 536:176–185

Zeidler S, Kätzel U, Kreis P (2013) Systematic investigation on the influence of solutes on the separation behavior of a PDMS membrane in organic solvent nanofiltration. J Membr Sci 429:295–303

Soltane HB, Roizard D, Favre E (2016) Study of the rejection of various solutes in OSN by a composite polydimethylsiloxane membrane: investigation of the role of solute affinity. Sep Purif Technol 161:193–201

Thiermeyer Y, Blumenschein S, Skiborowski M (2021) Fundamental insights into the rejection behavior of polyimide-based OSN membranes. Sep Purif Technol 265:118492

Li Y, Xue J, Zhang X, Cao B, Li P (2019) Formation of macrovoid-free PMDA-MDA polyimide membranes using a gelation/non-solvent-induced phase separation method for organic solvent nanofiltration. Ind Eng Chem Res 58:6712–6720

Xing DY, Chan SY, Chung TS (2014) The ionic liquid [EMIM]OAc as a solvent to fabricate stable polybenzimidazole membranes for organic solvent nanofiltration. Green Chem 16:1383–1392

Aburabie J, Emwas AH, Peinemann KV (2019) Silane-crosslinked asymmetric polythiosemicarbazide membranes for organic solvent nanofiltration. Macromol Mater Eng 304:1800551

Aburabie J, Neelakanda P, Karunakaran M, Peinemann KV (2015) Thin-film composite crosslinked polythiosemicarbazide membranes for organic solvent nanofiltration (OSN). React Funct Polym 86:225–232

Sun SP, Chung TS, Lu KJ, Chan SY (2014) Enhancement of flux and solvent stability of Matrimid®thin-film composite membranes for organic solvent nanofiltration. AIChE J 60:3623–3633

Lu TD, Chen BZ, Wang J, Jia TZ, Cao XL, Wang Y, Xing W, Lau CH, Sun SP (2018) Electrospun nanofiber substrates that enhance polar solvent separation from organic compounds in thin-film composites. J Mate Chem A 6:15047–15056

Acknowledgements

National College Students Innovation and Entrepreneurship Training Program, Grant Number: 202010377024. University Natural Science Research Key Project of Anhui Province, Grant Number: KJ2020A0707.

Author information

Authors and Affiliations

Contributions

AZ conceptualization, resources, writing, supervision. YW software. AMMA formal analysis. DC methodology. YW review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhou, A., Wang, Y., Almijbilee, M.M.A. et al. A thin-film composite polyarylester membrane prepared from orcinol and trimesoyl chloride for organic solvent nanofiltration. Iran Polym J 31, 1021–1032 (2022). https://doi.org/10.1007/s13726-022-01054-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01054-8