Abstract

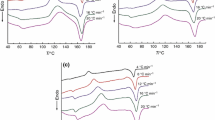

The effects of three different fillers (i.e., talc, calcium carbonate, and cassava starch) and surface functionalization by 3-aminopropyltriethoxysilane (APTES) and vinyltriethoxysilane (VTES) on morphology, thermal and tensile properties of the poly(lactic acid) (PLA) composites were comparatively examined. Dynamic differential scanning calorimetry (DSC) results revealed that the incorporation of filler can facilitate the cold crystallization of PLA, as confirmed by lowered cold crystallization temperature. By fitting DSC data with Avrami model, the highest isothermal cold crystallization rate constant k and the shortest crystallization half time t1/2 were obtained for the PLA/talc composites under isothermal temperature of 100 °C, implying that talc was the most effective nucleating agent for PLA in this study. The average Avrami index n of neat PLA and its composites lay within the same range of 3.0–3.6, which reflected the three-dimensional spherulitic growth of PLA with the mixture of instantaneous nuclei and sporadic nuclei. In comparison with the composite cast films, the thermoformed films had higher degree of crystallinity as well as higher tensile strength and Young’s modulus owing to the chain orientation upon annealing. Furthermore, the addition of silane-treated talc, especially APTES-treated talc, fastened cold crystallization rate and enhanced tensile properties because of the improved interfacial interaction between talc particles and PLA matrix.

Similar content being viewed by others

References

Di Lorenzo ML, Androsch R (2018) Industrial applications of poly(lactic acid). Springer, Cham

Sin LT, Tueen BS (2019) Polylactic acid: a practical guide for the processing, manufacturing, and applications of PLA. William Andrew, Oxford

Muller J, González-Martínez C, Chiralt A (2017) Combination of poly(lactic) acid and starch for biodegradable food packaging. Materials 10:E952. https://doi.org/10.3390/ma10080952

Alvarado N, Romero J, Torres A, Dicastillo CLD, Rojas A, Galotto MJ, Guarda A (2018) Supercritical impregnation of thymol in poly(lactic acid) filled with electrospun poly(vinyl alcohol)-cellulose nanocrystals nanofibers: development an active food packaging material. J Food Eng 217:1–10

Feng C, Yuan X, Chu K, Zhang H, Ji W, Rui M (2019) Preparation and optimization of poly(lactic acid) nanoparticles loaded with fisetin to improve anti-cancer therapy. Int J Biol Macromol 125:700–710

Singhvi MS, Zinjarde SS, Gokhale DV (2019) Polylactic acid: synthesis and biomedical applications. J Appl Microbiol 127:1612–1626. https://doi.org/10.1111/jam.14290

Huang T, Yamaguchi M (2017) Effect of cooling conditions on the mechanical properties of crystalline poly(lactic acid). J Appl Polym Sci 134:44960

Deetuam C, Samthong C, Pratumpol P, Somwangthanaroj A (2017) Improvement in morphology, mechanical and thermal properties of films produced by reactive blending of poly(lactic acid)/natural rubber latex with dicumyl peroxide. Iran Polym J 26:615–628

Auras RA, Lim L-T, Selke SEM, Tsuji H (2010) Poly(lactic acid): synthesis, structures, properties, processing, and applications. Wiley, New Jersey

Coppola B, Cappetti N, Di Maio L, Scarfalo P, Incarnato L (2018) 3D printing of PLA/clay nanocomposites: influence of printing temperature on printed samples properties. Materials 11:E1947. https://doi.org/10.3390/ma11101947

Abdallah W, Mirzadeh A, Tan V, Kamal MR (2019) Influence of nanoparticle pretreatment on the thermal, rheological and mechanical properties of PLA-PBSA nanocomposites incorporating cellulose nanocrystals or montmorillonite. Nanomaterials 9:E29. https://doi.org/10.3390/nano9010029

Lule Z, Kim J (2019) Nonisothermal crystallization of surface-treated alumina and aluminum nitride-filled polylactic acid hybrid composites. Polymers 11:E1077. https://doi.org/10.3390/polym11061077

Bher A, Unalan IU, Auras R, Rubino M, Schvezov CE (2018) Toughening of poly(lactic acid) and thermoplastic cassava starch reactive blends using graphene nanoplatelets. Polymers 10:95. https://doi.org/10.3390/polym10010095

Petchwattana N, Narupai B (2019) Synergistic effect of talc and titanium dioxide on poly(lactic acid) crystallization: an investigation on the injection molding cycle time reduction. J Polym Env 27:837–846

Nanthananon P, Seadan M, Pivsa-Art S, Hamada H, Suttiruengwong S (2018) Facile preparation and characterization of short-fiber and talc reinforced poly(lactic acid) hybrid composite with in situ reactive compatibilizers. Materials 11:E1183. https://doi.org/10.3390/ma11071183

Petchwattana N, Covavisaruch S, Petthai S (2014) Influence of talc particle size and content on crystallization behavior, mechanical properties and morphology of poly(lactic acid). Polym Bull 71:1947–1959

Tang H, Dong Q, Liu P, Ding Y, Wang F, Gao C, Zhang S, Yang M (2016) Isothermal crystallization of polypropylene/surface modified silica nanocomposites. Sci China Chem 59:1283–1290

Sabatini V, Farina H, Basilissi L, Silvestro GD, Ortenzi MA (2015) The use of epoxy silanes on montmorillonite: an effective way to improve thermal and theological properties of PLA/MMT nanocomposites obtained via "in situ" polymerization. J Nanomater. https://doi.org/10.1155/2015/418418

Nakamura Y, Nishida Y, Fukuda T, Fujii S, Sasaki M (2013) Mechanical properties of silane-treated silica particle-filled polyisoprene composites: influence of the alkoxy group mixing ratio in silane coupling agent containing. J Appl Polym Sci 128:2548–2555

Eng CC, Ibrahim NA, Zainuddin N, Ariffin H, Yunus WMZW (2014) Impact strength and flexural properties enhancement of methacrylate silane treated oil palm mesocarp fiber reinforced biodegradable hybrid composites. Sci World J. https://doi.org/10.1155/2014/213180

Sibeko MA, Luyt AS (2014) Preparation and characterization of vinylsilane crosslinked low-density polyethylene composites filled with nano clays. Polym Bull 71:637–657

Kusuktham B, Teeranachaideekul P (2014) Mechanical properties of high density polyethylene/modified calcium silicate composites. Silicon 6:179–189

Singha AS, Rana AK (2013) Effect of aminopropyltriethoxysilane (APS) treatment on properties of mercerized lignocellulosic Grewia optiva fiber. J Polym Environ 21:141–150

Li Q, Gao X, Cheng W, Han G (2017) Effect of modified red pottery clay on the moisture absorption behavior and weatherability of polyethylene-based wood-plastic composites. Materials 10:111. https://doi.org/10.3390/ma10020111

Salon MCB, Belgacem MN (2011) Hydrolysis-condensation kinetics of different silane coupling agents. Phosphorus Sulfur Silicon Relat Elem 186:240–254

Fischer EW, Sterzel HJ, Wegner G (1973) Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid Z Z Polym 251:980–990

Battegazzore D, Bocchini S, Frache A (2011) Crystallization kinetics of poly(lactic acid)-talc composites. Express Polym Lett 5:849–858

Shi N, Dou Q (2014) Crystallization behavior, morphology, and mechanical properties of poly(lactic acid)/tributyl citrate/treated calcium carbonate composites. Polym Compos 35:1570–1582

Zhang J, Tashiro K, Tsuji H, Domb AJ (2008) Disorder-to-order phase transition and multiple melting behavior of poly(L-lactide) investigated by simultaneous measurements of WAX and DSC. Macromolecules 41:1352–1357

Pan P, Zhu B, Kai W, Dong T, Inoue Y (2008) Polymorphic transition in disordered poly(L-lactide) crystals by annealing at elevated temperatures. Macromolecules 41:4296–4304

Shakoor A, Thomas NL (2014) Talc as nucleating agent and reinforcing filler in poly(lactic acid) composites. Polym Eng Sci 54:64–70

Samthong C, Deetuam C, Yamaguchi M, Praserthdam P, Somwangthanaroj A (2016) Effects of size and shape of dispersed poly(butylene terephthalate) on isothermal crystallization kinetics and morphology of poly(lactic acid) blends. Polym Eng Sci 56:258–268

Hoffman JD, David GT, Laurizten JI (1976) In: Treatise on solid state chemistry: crystalline and non-crystalline solid, N Hannay (ed), Plenum, New York

Avrami M (1940) Kinetics of phase change. II Transformation-time relations for random distribution of nuclei. J Chem Phys 8:212–225

Lorenzo AT, Arnal ML, Albuerne J, Müller AJ (2007) DSC isothermal polymer crystallization kinetics measurements and the use of the Avrami equation to fit the data: Guidelines to avoid common problems. Polym Test 26:222–231

Zhang J, Tsuji H, Noda I, Ozaki Y (2004) Structural changes and crystallization dynamics of poly(L-lactide) during the cold-crystallization process investigated by infrared and two-dimensional infrared correlation. Macromolecules 37:6433–6439

Anderson KS, Hillmyer MA (2006) Melt preparation and nucleation efficiency of polylactide stereocomplex crystallites. Polymer 47:2030–2035

Blagojević SL, Šturlić BZ, Igrec I (2013) Influence of silica nanofiller on the isothermal crystallization and melting of polyurethane elastomer. J Appl Polym Sci 129:1466–1475

Huda MS, Drzal LT, Mohanty AK, Misra M (2007) The effect of silane treated- and untreated-talc on the mechanical and physico-mechanical properties of poly(lactic acid)/newspaper fibers/talc hybrid composites. Compos B Eng 38:367–379

Friedrich K, Breuer U (2015) Multifunctionality of polymer composites: challenges and new solutions. William Andrew, New York

Auriemma F, Alfonso GC, Rosa CD (2017) Polymer crystallization I: From chain microstructure to processing. Springer, Cham

Acknowledgements

The authors sincerely acknowledge the financial support from the Ratchadaphisek Somphot Fund for Postdoctoral Fellowship, Chulalongkorn University, Thailand.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deetuam, C., Samthong, C., Choksriwichit, S. et al. Isothermal cold crystallization kinetics and properties of thermoformed poly(lactic acid) composites: effects of talc, calcium carbonate, cassava starch and silane coupling agents. Iran Polym J 29, 103–116 (2020). https://doi.org/10.1007/s13726-019-00778-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-019-00778-4