Abstract

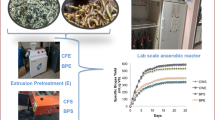

This research aimed to appraise the promising biogas generation from dragon fruit branches co-digested with pig dung. Biochemical methane potential assay was employed for effective biogas production via the optimized ratio between branches and pig dung, the ratio between feedstock and inoculum, the ratio between solid mixture and water, the percentage of added seedings, and incubating temperatures. Each batch was operated for 17 to 22 days, depending on the quantities of branches, dung, inoculum, water, added seedings, and incubating temperature. The biogas productivity was substantially intensified in the first eight to fourteen working days before decreasing in the following days. The maximized accumulated biogas capacity (2628 mL) and biogas yield (63.71 mL/g volatile solid) were achieved under the optimal conditions of 50% branches and 50% pig dung (w/w), 1 g feedstock/2 mL inoculum, 1 g solid mixture/5 mL water, 20% added seedings, and 27 °C incubating temperature. Furthermore, this output (63.71 mL/g volatile solid) was boosted by 128.18% as compared to the biogas yield from sole dragon fruit branches at the anaerobic conditions of 1 g feedstock/1 mL inoculum, 1 g solid mixture/4 mL water, 10% added seedings, and 35 °C incubating temperature (27.92 mL/g volatile solid). Based on these outputs, dragon fruit branches are a promising material for biogas production, which gains economic profits for this plant and benefits sustainable development in green energy and waste valorization.

Graphical abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available for the corresponding author upon reasonable request.

Abbreviations

- BMP:

-

biochemical methane potential

- VS:

-

volatile solid

References

Guerrero LA, Maas G, Hogland W (2013) Solid waste management challenges for cities in developing countries. Waste Management 33(1):220–232

Nikiema M, Somda M, Adéoti K, Traoré D, Baba-Moussa F, Toukourou F, Dianou D, Traore A, Somda M, Kifouli A, Ba-Ba-Moussa F, Fatiou T (2017) Optimization of biogas production from organic municipal waste: development of activated sludge as digesters inoculum. Journal of Environmental Protection 8:1674–1687

World Energy Council (2016) World energy resources waste to energy. https://smartnet.niua.org/sites/default/files/resources/weresources_waste_to_energy_2016.pdf. Accessed 1 Aug 2021

Ma Y, Liu Y (2019) Turning food waste to energy and resources towards a great environmental and economic sustainability: an innovative integrated biological approach. Biotechnology Advances 37(7):107414

Mofijur M, Kusumo F, Fattah IMR, Mahmudul HM, Rasul MG, Shamsuddin AH, Mahlia TMI (2020) Resource recovery from waste coffee grounds using ultrasonic-assisted technology for bioenergy production. Energies 13(7):1770

Uddin MN, Siddiki SYA, Mofijur M, Djavanroodi F, Hazrat MA, Show PL, Ahmed SF, Chu Y-M (2021) Prospects of bioenergy production from organic waste using anaerobic digestion technology: a mini review. Front Energy Res 9(33)

Zamri MFMA, Hasmady S, Akhiar A, Ideris F, Shamsuddin AH, Mofijur M, Fattah IMR, Mahlia TMI (2021) A comprehensive review on anaerobic digestion of organic fraction of municipal solid waste. Renewable and Sustainable Energy Reviews 137:110637

Zabed HM, Akter S, Yun J, Zhang G, Zhang Y, Qi X (2020) Biogas from microalgae: technologies, challenges and opportunities. Renewable and Sustainable Energy Reviews 117:109503

United Nations (2015) Transforming our world: The 2030 agenda for sustainable development. United Nations, Department of Economic and Social Affairs

The Government of Vietnam (2015) Approving the Vietnam’s renewable energy development strategy up to 2030 with an outlook to 2050, Vietnam

Ming C, Rizwanul Fattah IM, Chan QN, Pham PX, Medwell PR, Kook S, Yeoh GH, Hawkes ER, Masri AR (2018) Combustion characterization of waste cooking oil and canola oil based biodiesels under simulated engine conditions. Fuel 224:167–177

Mahlia TMI, Syazmi ZAHS, Mofijur M, Abas AEP, Bilad MR, Ong HC, Silitonga AS (2020) Patent landscape review on biodiesel production: technology updates. Renewable and Sustainable Energy Reviews 118:109526

Balat M, Balat H (2009) Biogas as a renewable energy source—a review. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 31(14):1280–1293

Crane JH, Balerdi CF (2005) Pitaya (dragon fruit) growing in the Florida home landscape. University of Florida. https://edis.ifas.ufl.edu/pdffiles/HS/HS30300.pdf. Accessed 1 June 2021

Jiang Y-L, Liao Y-Y, Lin T-S, Lee C-L, Yen C-R, Yang W-J (2012) The photoperiod-regulated bud formation of red pitaya (Hylocereus sp.). HortScience Horts 47(8):1063

Reddy DAK (2021) Dragon fruit – a new introduction in the Indian market. Just Agriculture e-Magazine 1(8):12–15

Balendres MA, Bengoa JC (2019) Diseases of dragon fruit (Hylocereus species): etiology and current management options. Crop Protection 126:104920

Hieu NT, Hoa NV (2015) Management strategies of major pitaya diseases in Vietnam. In: Improving pitaya production and marketing: international workshop proceedings, Fengshan, Kaohsiung, Taiwan, pp 129–142

Tuan LNA, Du BD, Ha LDT, Dzung LTK, Van Phu D, Hien NQ (2019) Induction of chitinase and brown spot disease resistance by oligochitosan and nanosilica–oligochitosan in dragon fruit plants. Agricultural Research 8(2):184–190

Md A, Som AW (2018) Performance study of dragon fruit foliage as a plant-based coagulant for treatment of palm oil mill effluent from three-phase decanters. Bioresources 13:4290–4300

Ismail O, Abdel-Aziz M, GhareebR M, Hassan YA (2017) Exploring the biological activities of the Hylocereus polyrhizus extract. Journal of Innovations in Pharmaceutical and Biological Sciences 4(1):1–6

Tsai Y, Lin C-G, Chen W-L, Huang Y-C, Chen C-Y, Huang K-F, Yang C-H (2019) Evaluation of the antioxidant and wound-healing properties of extracts from different parts of Hylocereus polyrhizus. Agronomy 9(1):27

Idris J, Md Som A, Musa M, Ku Hamid KH, Husen R, Muhd Rodhi MN (2013) Dragon fruit foliage plantbBased coagulant for treatment of concentrated latex effluent: comparison of treatment with ferric sulfate. Journal of Chemistry 2013:230860

Tien NNT, Le NL, Khoi TT, Richel A (2022) Influence of location, weather condition, maturity, and plant disease on chemical profiles of dragon fruit (Hylocereus spp.) branches grown in Vietnam. Biomass Convers Biorefin 1–13

Juárez-Cruz A, Livera M, Sosa-Montes E, Goytia-Jiménez M, González-Hernández V, Bárcena-Gama R (2012) Composición química de tallos inmaduros de Acanthocereus spp. e Hylocereus undatus (Haw.). Britton & Rose. Revista Fitotecnia Mexicana publ. por la Sociedad Mexicana de Fitogenética 35:171–175

Ortiz-Hernández YD, Carrillo-Salazar JA (2012) Pitahaya (Hylocereus spp.): a short review. Comunicata Scientiae 3(4):220–237

Som AM, Ahmat N, Abdul Hamid HA, Azizuddin N (2019) A comparative study on foliage and peels of Hylocereus undatus (white dragon fruit) regarding their antioxidant activity and phenolic content. Heliyon 5(2):e01244

Ameen F, Ranjitha J, Ahsan N, Shankar V (2021) Co-digestion of microbial biomass with animal manure in three-stage anaerobic digestion. Fuel 306:121746

Borowski S, Domański J, Weatherley L (2014) Anaerobic co-digestion of swine and poultry manure with municipal sewage sludge. Waste Management 34(2):513–521

Sompong O, Boe K, Angelidaki I (2012) Thermophilic anaerobic co-digestion of oil palm empty fruit bunches with palm oil mill effluent for efficient biogas production. Applied Energy 93:648–654

Kougias PG, Kotsopoulos TA, Martzopoulos GG (2014) Effect of feedstock composition and organic loading rate during the mesophilic co-digestion of olive mill wastewater and swine manure. Renewable Energy 69:202–207

Liu C, Li H, Zhang Y, Liu C (2016) Improve biogas production from low-organic-content sludge through high-solids anaerobic co-digestion with food waste. Bioresource Technology 219:252–260

Mata-Alvarez J, Dosta J, Macé S, Astals S (2011) Codigestion of solid wastes: a review of its uses and perspectives including modeling. Critical Reviews in Biotechnology 31(2):99–111

Tsapekos P, Kougias PG, Angelidaki I (2015) Anaerobic mono- and co-digestion of mechanically pretreated meadow grass for biogas production. Energy & Fuels 29(7):4005–4010

Kainthola J, Kalamdhad AS, Goud VV (2019) A review on enhanced biogas production from anaerobic digestion of lignocellulosic biomass by different enhancement techniques. Process Biochemistry 84:81–90

Sluiter A, Hames B, Hyman D, Payne C, Ruiz R, Scarlata C, Sluiter J, Templeton D, Wolfe J (2008) Determination of total solids in biomass and total dissolved solids in liquid process samples. In: NREL Laboratory Analytical Procedure (NREL/TP-510-42621)

Standard Methods Committee of the American Public Health Association (2017) American Water Works Association Water Environment Federation 5220 chemical oxygen demand (COD). In: Standard methods for the examination of water and wastewater. American Public Health Association

Pham CH, Triolo JM, Cu TTT, Pedersen L, Sommer SG (2013) Validation and recommendation of methods to measure biogas production potential of animal manure. Asian-Australas J Anim Sci 26(6):864–873

Standard V (2018) 4630 (2006) Fermentation of organic materials, characterisation of the substrates, sampling, collection of material data, fermentation test. VDI-Handbuch Energietechnik, VDI-Handbuch Energietechnik

Obileke K, Nwokolo N, Makaka G, Mukumba P, Onyeaka H (2021) Anaerobic digestion: technology for biogas production as a source of renewable energy—a review. Energy & Environment 32(2):191–225

Durán DA, Figueroa Á, Gualdrón MA, Sierra R (2018) Potential of tropical fruit waste in bioenergy processes and bioproducts design. 26th European Biomass Conference and Exhibition, pp 166–174

Rambo MKD, Schmidt FL, Ferreira MMC (2015) Analysis of the lignocellulosic components of biomass residues for biorefinery opportunities. Talanta 144:696–703

Li Y, Zhang R, Liu G, Chen C, He Y, Liu X (2013) Comparison of methane production potential, biodegradability, and kinetics of different organic substrates. Bioresource Technology 149:565–569

Menardo S, Cacciatore V, Balsari P (2015) Batch and continuous biogas production arising from feed varying in rice straw volumes following pre-treatment with extrusion. Bioresource Technology 180:154–161

Novais RM, Gameiro T, Carvalheiras J, Seabra MP, Tarelho LAC, Labrincha JA, Capela I (2018) High pH buffer capacity biomass fly ash-based geopolymer spheres to boost methane yield in anaerobic digestion. Journal of Cleaner Production 178:258–267

Podmirseg SM, Seewald MSA, Knapp BA, Bouzid O, Biderre-Petit C, Peyret P, Insam H (2013) Wood ash amendment to biogas reactors as an alternative to landfilling? A preliminary study on changes in process chemistry and biology. Waste Management & Research 31(8):829–842

Gerardi MH (2003) The microbiology of anaerobic digesters, wastewater microbiology. John Wiley & Sons, Inc, New Jersey

Merlin Christy P, Gopinath LR, Divya D (2014) A review on anaerobic decomposition and enhancement of biogas production through enzymes and microorganisms. Renewable and Sustainable Energy Reviews 34:167–173

Supaphol S, Jenkins SN, Intomo P, Waite IS, O'Donnell AG (2011) Microbial community dynamics in mesophilic anaerobic co-digestion of mixed waste. Bioresource Technology 102(5):4021–4027

Yadvika S, Sreekrishnan TR, Kohli S, Rana V (2004) Enhancement of biogas production from solid substrates using different techniques--a review. Bioresource Technology 95(1):1–10

Abbasi T, Tauseef SM, Abbasi SA (2012) Biogas and biogas energy: an introduction Biogas energy. Springer, New York, NY, pp 1–10

Yan C, Liu Y, Cui X, Cao L, Xiong J, Zhang Q, Wang Y, Ruan R (2022) Improving the efficiency of anaerobic digestion: domesticated paddy soil microbes enhance the hydrolytic acidification of rice straw and pig manure. Bioresource Technology 345:126570

Pachaiyappan S, Elamvazhuthi P, Dhamodharan M, Seshadri S, Amm S (2014) Biogas production from water hyacinth blended with cow dung. Indian Journal of Energy 3(1):134–139

Mussatto SI, Fernandes M, Milagres AMF, Roberto IC (2008) Effect of hemicellulose and lignin on enzymatic hydrolysis of cellulose from brewer’s spent grain. Enzyme and Microbial Technology 43(2):124–129

Pham CH, Saggar S, Vu CC, Tate KR, Tran TTT, Luu TT, Ha HT, Nguyen HLT, Sommer SG (2017) Biogas production from steer manures in Vietnam: effects of feed supplements and tannin contents. Waste Management 69:492–497

Amon T, Amon B, Kryvoruchko V, Zollitsch W, Mayer K, Gruber L (2007) Biogas production from maize and dairy cattle manure—influence of biomass composition on the methane yield. Agriculture, Ecosystems & Environment 118(1):173–182

Phuong NL, Quyen LTT, Huyen NTN, Huynh NTN, Trang NTD, Ngan NVC (2015) Biogas production from corn (Zea mays) stalks: effects of size. J Fish Sci Technol Special 69–75

Neves L, Oliveira R, Alves MM (2004) Influence of inoculum activity on the bio-methanization of a kitchen waste under different waste/inoculum ratios. Process Biochemistry 39(12):2019–2024

Angelidaki I, Alves M, Bolzonella D, Borzacconi L, Campos JL, Guwy AJ, Kalyuzhnyi S, Jenicek P, van Lier JB (2009) Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Science and Technology 59(5):927–934

El-Mashad HM, van Loon WKP, Zeeman G, Bot GPA, Lettinga G (2006) Effect of inoculum addition modes and leachate recirculation on anaerobic digestion of solid cattle manure in an accumulation system. Biosystems Engineering 95(2):245–254

Xu SY, Karthikeyan OP, Selvam A, Wong JWC (2014) Microbial community distribution and extracellular enzyme activities in leach bed reactor treating food waste: effect of different leachate recirculation practices. Bioresource Technology 168:41–48

Dixon PJ, Ergas SJ, Mihelcic JR, Hobbs SR (2019) Effect of substrate to inoculum ratio on bioenergy recovery from food waste, yard waste, and biosolids by high solids anaerobic digestion. Environmental Engineering Science 36(12):1459–1465

Hobbs SR, Landis AE, Rittmann BE, Young MN, Parameswaran P (2018) Enhancing anaerobic digestion of food waste through biochemical methane potential assays at different substrate: inoculum ratios. Waste Management 71:612–617

Asante Sackey D, Tetteh E, Nkosi N, Boakye G, Ansah Amano K, Boamah B, Armah E (2018) Effects of inoculum to feedstock ratio on anaerobic digestion for biogas production. International Journal of Hydrology 2(5):567–571

Khadka A, Parajuli A, Dangol S, Thapa B, Sapkota L, Carmona-Martínez AA, Ghimire A (2022) Effect of the substrate to inoculum ratios on the kinetics of biogas production during the mesophilic anaerobic digestion of food waste. Energies.

Artanti D, Saputro R, Budiyono B (2012) Biogas production from cow manure. International Journal of Renewable Energy Development (IJRED) 1:61–64

Jeppu GP, Janardhan J, Kaup S, Janardhanan A, Mohammed S, Acharya S (2022) Effect of feed slurry dilution and total solids on specific biogas production by anaerobic digestion in batch and semi-batch reactors. Journal of Material Cycles and Waste Management 24(1):97–110

Putri DA, Saputro RR, Budiyono B (2012) Biogas production from cow manure. International Journal of Renewable Energy Development (IJRED) 1(2):4

Budiyono B, Widiasa IN, Seno J, Sunarso S (2010) The influence of total solid contents on biogas yield from cattle manure using rumen fluid inoculum. Energy Res J 1(1):6–11

Liu Z, Lv J (2016) The effect of total solids concentration and temperature on biogas production by anaerobic digestion. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 38(23):3534–3541

Liotta F, d'Antonio G, Esposito G, Fabbricino M, van Hullebusch ED, Lens PN, Pirozzi F, Pontoni L (2014) Effect of total solids content on methane and volatile fatty acid production in anaerobic digestion of food waste. Waste Management & Research 32(10):947–953

Battista F, Fino D, Ruggeri B (2014) Polyphenols concentration’s effect on the biogas production by wastes derived from olive oil production. Chemical. Engineering Transactions 38

Leite VD, Viriato CL, de Sousa JT, Lopes WS, de Oliveira EG (2018) Anaerobic co-digestion of organic waste: influences particle size and concentration total solids. The Journal of Solid Waste Technology and Management 44(2):153–162

Chandra R, Vijay VK, Subbarao PMV (2006) A study on biogas generation from non-edible oil seed cakes: potential and prospects in India. In: 2nd Joint International Conference on “Sustainable Energy and the Environment”, Bangkok, Thailand

Elbeshbishy E, Nakhla G, Hafez H (2012) Biochemical methane potential (BMP) of food waste and primary sludge: influence of inoculum pre-incubation and inoculum source. Bioresource Technology 110:18–25

Li Y, Feng L, Zhang R, He Y, Liu X, Xiao X, Ma X, Chen C, Liu G (2013) Influence of inoculum source and pre-incubation on bio-methane potential of chicken manure and corn stover. Applied Biochemistry and Biotechnology 171(1):117–127

Moreno-Andrade I, Buitrón G (2004) Influence of the origin of the inoculum on the anaerobic biodegradability test. Water Science and Technology 49(1):53–59

Pearse LF, Hettiaratchi JP, Kumar S (2018) Towards developing a representative biochemical methane potential (BMP) assay for landfilled municipal solid waste – a review. Bioresource Technology 254:312–324

Filer J, Ding HH, Chang S (2019) Biochemical methane potential (BMP) assay method for anaerobic digestion research. Water 11(5):921

Xi Y, Chang Z, Ye X, Xu R, Du J, Chen G (2014) Methane production from wheat straw with anaerobic sludge by heme supplementation. Bioresource Technology 172:91–96

Jeihanipour A, Niklasson C, Taherzadeh MJ (2011) Enhancement of solubilization rate of cellulose in anaerobic digestion and its drawbacks. Process Biochemistry 46(7):1509–1514

Levén L, Eriksson AR, Schnürer A (2007) Effect of process temperature on bacterial and archaeal communities in two methanogenic bioreactors treating organic household waste. FEMS Microbiology Ecology 59(3):683–693

Luo G, De Francisci D, Kougias PG, Laura T, Zhu X, Angelidaki I (2015) New steady-state microbial community compositions and process performances in biogas reactors induced by temperature disturbances. Biotechnology for Biofuels 8(1):3

Zhu X, Treu L, Kougias PG, Campanaro S, Angelidaki I (2018) Converting mesophilic upflow sludge blanket (UASB) reactors to thermophilic by applying axenic methanogenic culture bioaugmentation. Chemical Engineering Journal 332:508–516

Angelidaki I, Ellegaard L (2003) Codigestion of manure and organic wastes in centralized biogas plants. Applied Biochemistry and Biotechnology 109(1):95–105

Bouallagui H, Haouari O, Touhami Y, Ben Cheikh R, Marouani L, Hamdi M (2004) Effect of temperature on the performance of an anaerobic tubular reactor treating fruit and vegetable waste. Process Biochemistry 39(12):2143–2148

Suhartini S, Heaven S, Banks CJ (2014) Comparison of mesophilic and thermophilic anaerobic digestion of sugar beet pulp: performance, dewaterability and foam control. Bioresource Technology 152:202–211

Ghasimi DSM, Tao Y, de Kreuk M, Zandvoort MH, van Lier JB (2015) Microbial population dynamics during long-term sludge adaptation of thermophilic and mesophilic sequencing batch digesters treating sewage fine sieved fraction at varying organic loading rates. Biotechnology for Biofuels 8(1):171

Kougias PG, Angelidaki I (2018) Biogas and its opportunities—a review. Frontiers of Environmental Science & Engineering 12(3):14

Funding

This project is granted by ARES (Belgium)–PRD 2019 “Innovation in disease control combined with the management and valorisation of dragon fruit culture waste” (Belgium–Vietnam).

Author information

Authors and Affiliations

Contributions

Nguyen Ngoc Thanh Tien: conceptualization, methodology, formal analysis, investigation, writing of original draft, writing including review and editing, and visualization; Hoang Gia Phuc: methodology, formal analysis, and investigation; Hai T. H. Nguyen: methodology, formal analysis, investigation, and writing including review and editing; Ngoc Lieu Le: conceptualization, methodology, validation, resources, writing including review and editing, and supervision; Tran Tien Khoi: conceptualization, resources, validation, writing including review and editing, and supervision; Aurore Richel: conceptualization, validation, resources, writing including review and editing, supervision, project administration, and funding acquisition.

Corresponding authors

Ethics declarations

Ethical approval

The authors declare that ethics approval was not required for this research.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tien, N.N.T., Phuc, H.G., Nguyen, H.T.H. et al. Productivity of biogas production from dragon fruit branches co-digested with pig dung. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03902-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03902-w