Abstract

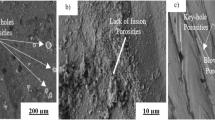

Cobalt is used in applications that require high densities and good mechanical properties. Cobalt powder is used in batteries, cemented carbides, stainless steel, machine tools and also in manufacturing of metal matrix diamond tools designed for the cutting and drilling of hard rocks and concrete. This study aimed to investigate the structural properties and compare the mechanical and micro structural properties of two different cobalt powders, specifically the spherical grain (Co-S) and rod-like grain shapes (Co-R), to enhance the cutting performances of the diamond cutting tools. The flow properties of the powders, as a function of the shear strain rate, were determined using Freeman Technology (FT4) rheometer analysis. The microstructural characterizations were conducted using scanning electron microscopy (SEM)-energy-dispersive spectroscopy (EDS) and X-ray diffraction (XRD) analyses, and the crystallite size values were calculated using the Williamson-Hall method. The mechanical characterizations were conducted using the density measurement, hardness, compression test, and wear test. Based on the results of the FT4 rheometer analysis, the Co-S powder had higher compressibility and air permeability compared to the Co-R powder. The SEM analysis of the sintered samples revealed multiple pores in the Co-R powder. The highest mechanical properties were obtained in the sintered sample of the S series. The most suitable Co powder for the preparation of metal matrix mixtures of diamond cutting tools produced using SPS was determined to be the Co-S series.

Similar content being viewed by others

References

Ersoy A, Atici U. Performance characteristics of circular diamond saws in cutting different types of rocks. Diamond and Related Materials. 2004; 13: 22–37. https://doi.org/https://doi.org/10.1016/j.diamond.2003.08.016

Ersoy A, Buyuksagis S, Atici U. Wear characteristics of circular diamond saws in the cutting of different hard abrasive rocks. Wear. 2005; 258:1422-1436. https://doi.org/https://doi.org/10.1016/j.wear.2004.09.060

Dhokey N.B, Utpat K, Gosavi A, Dhoka P. Hot-press sintering temperature response of diamond cutting tools and its correlation with wear mechanism. Journal of Refractory Metals and Hard Materials. 2013; 36: 289-293. https://doi.org/https://doi.org/10.1016/j.ijrmhm.2012.10.008

Nitkiewicz Z , Swierzy M. Tin influence on diamond–metal matrix hot pressed tools for stone cutting. Journal of Materials Processing Technology . 2006;175: 306–315. https://doi.org/https://doi.org/10.1016/j.jmatprotec.2005.04.056

Rosa LG, Fernandes JC, Anjinho CA, Coelho A, Amaral PM. Long-term performance of stone-cutting tools. Journal of Refractory Metals and Hard Materials. 2015; 49: 276-282. https://doi.org/https://doi.org/10.1016/j.ijrmhm.2014.05.021

Ganta A.J, Konyashin I, Ries B, McKie A, Nilen R.W.N, Pickles J. International Journal of Refractory Metals & Hard Materials.2018; 71;106–114. https://doi.org/10.1016/j.ijrmhm.2017.10.013

Xi X , Nie Z , Xu K , Ma L , Chen G , Zhang X , Zuo T. Int. Journal of Refractory Metals and Hard Materials.2013; 41: 90–93. https://doi.org/10.1016/j.ijrmhm.2013.02.008

Liua K, Wang Z, Yin Z, Cao L, Yuana J. Effect of Co content on microstructure and mechanical properties of ultrafine grained WC-Co cemented carbide sintered by spark plasma sintering. Ceramics International. 2018; 44: 18711–18718. https://doi.org/https://doi.org/10.1016/j.ceramint.2018.07.100

Kaplan M, Budak S. Bir Mermer Kesici Takımında Co Katkısının Mikroyapı ve Mekanik Özelliklere Etkisi. 6th International Advanced Technologies Symposium.Conference Paper 2011.

Molinari A, Marchetti F, Gialanella S, Scardi P, Tiziani A. Study of the diamond-matrix interface in hot-pressed cobalt-based tools. Materials Science and Engineering: A.1990; 130: 257-262. https://doi.org/https://doi.org/10.1016/0921-5093(90)90066-C

Chandrashekar M, Prasad K.V.S,Materialstoday: Proceedings. 2018;5: 7678–7684. https://doi.org/10.1016/j.matpr.2017.11.443

Xie Z, Ni S, Song M. Effect of Y2O3 doping on FCC to HCP phase transformation in cobalt produced by ball milling and spark plasma sintering. Powder Technology.2018; 324:1-4. https://doi.org/https://doi.org/10.1016/j.powtec.2017.10.044

Wanjun T, Donghua C. Mechanism of thermal decomposition of cobalt acetate tetrahydrate. Chemical Papers. 2007; 6: 329–332. DOI: https://doi.org/10.2478/s11696-007-0042-3

Samal P.K, Newkirk J.W. Powder Metallurgy. ASM Handbook. Vol 7.

Wu J, Tang J, Wei X, Ye N, Yu F. Preparation process and mechanism of ultra-fine spherical cobalt powders by hydrogen reduction of calcium cobaltite. Journal of Alloys and Compounds. 2017;726: 1119-1123. https://doi.org/https://doi.org/10.1016/j.jallcom.2017.08.070

Nakayamaa N, Horitab M, Sakagamia S, Mikic H, Miyazakid T, Takeishie H. Effect of powder shape and size on mechanical properties of Al thin plate formed by compression shearing method at room temperature. Procedia Engineering. 2014;81:1163 – 1168. https://doi.org/https://doi.org/10.1016/j.proeng.2014.10.282

Nouri A, Sola A. Metal particle shape: A practical perspective. Metal Powder Report. 2018;73: 276-282. https://doi.org/https://doi.org/10.1016/j.mprp.2018.04.001

Beckers D, Ellendt N, Fritsching U, Uhlenwinkel V. Impact of process flow conditions on particle morphology in metal powder production via gas atomization. Advanced Powder Technology. 2020; 31: 300-311. https://doi.org/https://doi.org/10.1016/j.apt.2019.10.022

Fariñas J.C, Moreno R, Pérez A, Garcíaa M.A, García-Hernándezc M, Salvador M.D, Borrell A. Microwave-assisted solution synthesis, microwave sintering and magnetic properties of cobalt ferrite. Journal of the European Ceramic Society. 2018; 38: 2360-2368. https://doi.org/https://doi.org/10.1016/j.jeurceramsoc.2017.12.052

Bokhonov B.B, Korchagina M.A, Ukhinaa A.V, Dudina D.V. Structural and morphological transformations in cobalt-carbon mixtures during ball milling, annealing and Spark Plasma Sintering. Vacuum. 2018; 157: 210-215. https://doi.org/https://doi.org/10.1016/j.vacuum.2018.08.052

Sakkaki M, Moghanlou F.S, Vajdi M, Asl M.S, Mohammadi M, Shokouhimehr M. Wear studies of spark plasma sintered ZrO2 reinforced Ti-6Al-4V alloy. Ceramics International. 2020; 46: 4998-5007. https://doi.org/https://doi.org/10.1016/j.ceramint.2019.10.240

Peng Z, Luo X, Xie Z, Yang M. Sintering behavior and mechanical properties of spark plasma sintering SiO2-MgO ceramics. Ceramics International. 2020; 46: 2585-2591. https://doi.org/https://doi.org/10.1016/j.ceramint.2019.09.267

Shankarab E, Prabu S.B. Influence of WC and cobalt additions on the microstructural and mechanical properties of TiCN-Cr3C2-nano-TiB2 cermets fabricated by spark plasma sintering. International Journal of Refractory Metals and Hard Materials.2017; 69: 110-118. https://doi.org/https://doi.org/10.1016/j.ijrmhm.2017.08.004

Freeman R. Measuring the flow properties of consolidated, conditioned and aerated powders - A comparative study using a powder rheometer and a rotational shear cell. Powder Technology. 2007;174: 25–33. https://doi.org/https://doi.org/10.1016/j.powtec.2006.10.016

25) Srinivasan R, Yogamalar R, Bose A.C. Structural and optical studies of yttrium oxide nanoparticles synthesized by co-precipitation method. Materials Research Bulletin. 2010; 45: 1165–1170. https://doi.org/https://doi.org/10.1016/j.materresbull.2010.05.020

Cleary, P W.The effect of particle shape on simple shear flows. Powder Technology. 2008; 179: 144–163. https://doi.org/https://doi.org/10.1016/j.powtec.2007.06.018

Nan W, Wang Y, Wang J. Numerical analysis on the fluidization dynamics of rodlike particles. Advanced Powder Technology. 2016; 27: 2265–2276. https://doi.org/https://doi.org/10.1016/j.apt.2016.08.015

Nan W, Ghadiri M, Wang Y. Analysis of powder rheometry of FT4: Effect of particle shape. Chemical Engineering Science. 2017; 173: 374-383. https://doi.org/https://doi.org/10.1016/j.ces.2017.08.004

Bharadwaj R, Ketterhagen W.R, Hancock B.C. Discrete element simulation study of a Freeman powder rheometer. Chemical Engineering Science. 2010; 65: 5747–5756. https://doi.org/https://doi.org/10.1016/j.ces.2010.04.002

Jakub H, David Z, Lucie J, Jiří Z, Jan N. Metal 2016 Conferences Paper.

Fu X, Huck D, Makein L, Armstrong B, Willen U, Freeman T. Effect of particle shape and size on flow properties of lactose powders. Particuology. 2012; 10: 203– 208. https://doi.org/https://doi.org/10.1016/j.partic.2011.11.003

Danjo K. Effect of particle shape on the compaction and flow properties of powders. Chemical and Pharmaceutical Bulletin. 1989; 37: 3070-3073. https://doi.org/https://doi.org/10.1248/cpb.37.3070

Zhou K, Liu B,Yao Y, Zhong K. Effects of grain size and shape on mechanical properties of nanocrystalline copper investigated by molecular dynamics. Materials Science and Engineering: A. 2014; 615: 92-97. https://doi.org/https://doi.org/10.1016/j.msea.2014.07.066

Uddin S.M, Mahmud T, Wolf C, Glanz C, Kolaric I, Volkmer C, Höller H, Wienecke U, Roth S, Fecht H. Effect of size and shape of metal particles to improve hardness and electrical properties of carbon nanotube reinforced copper and copper alloy composites. Composites Science and Technology.2010; 70: 2253–2257. https://doi.org/https://doi.org/10.1016/j.compscitech.2010.07.012

Wu J, Ruan C, Ma Y, Wang Y, Luo Y. Vital role of hydroxyapatite particle shape in regulating the porosity and mechanical properties of the sintered scaffolds. Journal of Materials Science & Technology. 2018; 34: 503–507. https://doi.org/https://doi.org/10.1016/j.jmst.2017.01.008

Acknowledgements

The authors are grateful to the Freeman Technology and Terrelab Company for allowing us to use an FT4 instrument for the experiment. They are also thankful for the technical support from Dr Rajeev Dattani.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bulut, B., Unal, F., Baydogan, M. et al. Effect of Particle Morphology on Physical, Mechanical and Wear Properties of Cobalt Metal Powders. Trans Indian Inst Met 74, 2345–2355 (2021). https://doi.org/10.1007/s12666-021-02331-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02331-5