Abstract

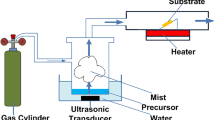

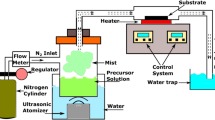

With the advancement of technology, inexpensive and highly scalable deposition techniques are extremely desirable for low-cost device fabrication. Aerosol-assisted chemical vapor deposition (AACVD) is a less complex and scalable deposition technique that works at atmospheric pressure. In this article, we demonstrate the growth of chromium oxide (Cr2O3) films onto n-type silicon substrates utilizing the AACVD method, leading to the first-ever p-Cr2O3/n-silicon heterojunction device by this method. In this paper, we have analyzed the effect of temperature and concentration of precursor solution on the morphology of the deposited films. The structural analysis of the Cr2O3 films shows a closely packed uniform structure with the root mean square (RMS) value of surface roughness varying from 1.6 nm to 5.99 nm. The maximum growth rate of 45.20 nm/min on silicon substrate was observed at 500 °C with 0.05 M precursor solution. X-ray photoelectron spectroscopy (XPS) showed a mixed phase layer, with the ratio of Cr3+ to Cr6+ for the film deposited at 450 °C, with 0.05 M precursor solution being 1.51 and increasing with the deposition temperature. The current–voltage characteristics showed a diode-like behavior with a high cut-in voltage of about 2 V. A high cut-in voltage exists due to a significant band offset at both the conduction band and valence band exists between Cr2O3 and silicon. The utilization of the AACVD technique to grow Cr2O3 on silicon substrate using chromium acetylacetonate as a precursor combined with the illustration of diode characteristics provide the novelty of this work.

Similar content being viewed by others

Availability of Data and Materials

All data are available as per request.

References

Susman MD, Feldman Y, Vaskevich A, Rubinstein I (2014) Chemical deposition of Cu2O nanocrystals with precise morphology control. ACS Nano 8:162–174. https://doi.org/10.1021/nn405891g

Gonzalez-Chan IJ, Moguel P, Oliva AI (2019) Deposition of ZnO thin films by chemical bath technique: physicochemical conditions and characterization. ECS J Solid State Sci Technol 8:P536–P544. https://doi.org/10.1149/2.0251909jss

Soonmin H (2022) A review of metal oxide thin films in solar cell applications. Int J Thin Film Sci Technol 11:37–45. https://doi.org/10.18576/ijtfst/110105

Lin W, Wu W, Liu Z et al (2018) Chromium trioxide hole-selective heterocontacts for silicon solar cells. ACS Appl Mater Interfaces 10:13645–13651. https://doi.org/10.1021/acsami.8b02878

Lin W, Wu W, Bao J et al (2018) Novel hole selective CrOx contact for dopant-free back contact silicon solar cells. Mater Res Bull 103:77–82. https://doi.org/10.1016/j.materresbull.2018.03.032

Xu Z, Peng S, Lin H et al (2021) Solution-processed copper-doped chromium oxide with tunable oxygen vacancy for crystalline silicon solar cells hole-selective contacts. Sol RRL 5:1–7. https://doi.org/10.1002/solr.202100064

Liu Z, Seo S, Lee EC (2013) Improvement of power conversion efficiencies in Cr2O 3-nanoparticle-embedded polymer solar cells. Appl Phys Lett 103. https://doi.org/10.1063/1.4822429

Ibarra Michel J, Dréon J, Boccard M et al (2022) Carrier-selective contacts using metal compounds for crystalline silicon solar cells. Prog Photovoltaics Res Appl 1–34. https://doi.org/10.1002/pip.3552

Kohli N, Singh O, Singh RC (2012) Sensing behaviour of tin doped chromium oxide gas sensor toward ethanol. Appl Phys A Mater Sci Process 109:585–590. https://doi.org/10.1007/s00339-012-7070-8

Dey S, Kumar VVP (2021) Supported and un-supported zinc and chromium oxide catalysts for lower temperature CO oxidation: a review. Environ Challenge 3:100061. https://doi.org/10.1016/j.envc.2021.100061

Ivanova T, Gesheva KA, Sharlandjiev P, Koserkova-Georgieva A (2007) Technology and optoelectronic properties of APCVD Cr2O3 and Mo-Cr mixed oxide thin films. Surf Coat Technol 201:9313–9318. https://doi.org/10.1016/j.surfcoat.2007.04.048

Khalaf MK, Al-kader DSA, Salh JM (2021) Annealing effect on structural and optical properties of Cr 2 O 3 thin films prepared by RF magnetron sputtering. IOP Conf Ser Mater Sci Eng 1105:012064. https://doi.org/10.1088/1757-899x/1105/1/012064

Khanna A, Bhat DG, Payzant EA (2006) Growth and characterization of chromium oxide thin films prepared by reactive ac magnetron sputtering. J Vac Sci Technol A Vacuum Surf Film 24:1870–1877. https://doi.org/10.1116/1.2244536

Tarre A, Aarik J, Mändar H et al (2008) Atomic layer deposition of Cr2O3 thin films: Effect of crystallization on growth and properties. Appl Surf Sci 254:5149–5156. https://doi.org/10.1016/j.apsusc.2008.02.016

Jõgiaas T, Tarre A, Mändar H et al (2022) Nanoindentation of chromium oxide possessing superior hardness among atomic-layer-deposited oxides. Nanomaterials 12. https://doi.org/10.3390/nano12010082

Arca E, Fleischer K, Shvets IV (2011) Magnesium, nitrogen codoped Cr2O3: A p-type transparent conducting oxide. Appl Phys Lett 99:2011–2014. https://doi.org/10.1063/1.3638461

Kamble VB, Umarji AM (2012) Chromium oxide thin films by ultrasonic nebulized spray pyrolysis of aqueous combustion mixture for gas sensing application. Proc - ISPTS-1, 1st Int Symp Phys Technol Sensors 181–184. https://doi.org/10.1109/ISPTS.2012.6260915

Ivanova T, Surtchev M, Gesheva K (2001) Characterization of CVD chromium oxide thin films. Phys Status Solidi Appl Res 184:507–513. https://doi.org/10.1002/1521-396X(200104)184:2%3c507::AID-PSSA507%3e3.0.CO;2-O

Carta G, Natali M, Rossetto G et al (2005) A comparative study of Cr2O3 thin films obtained by MOCVD using three different precursors. Chem Vap Depos 11:375–380. https://doi.org/10.1002/cvde.200406360

He D, Li S, Liu X et al (2014) Preparation of Cr2O3 film by MOCVD as hydrogen permeation barrier. Fusion Eng Des 89:35–39. https://doi.org/10.1016/j.fusengdes.2013.11.005

Kaneko K, Nomura T, Fujita S (2010) Corundum-structured α-phase Ga2O3-Cr2O3-Fe2O3 alloy system for novel functions. Phys Status Solidi Curr Top Solid State Phys 7:2467–2470. https://doi.org/10.1002/pssc.200983896

Dang GT, Suwa Y, Sakamoto M et al (2018) Growth of α-Cr2O3 single crystals by mist CVD using ammonium dichromate. Appl Phys Express 11:3–7. https://doi.org/10.7567/APEX.11.111101

Potter DB, Parkin IP, Carmalt CJ (2018) The effect of solvent on Al-doped ZnO thin films deposited via aerosol assisted CVD. RSC Adv 8:33164–33173. https://doi.org/10.1039/C8RA06417B

Potter DB, Powell MJ, Darr JA et al (2017) Transparent conducting oxide thin films of Si-doped ZnO prepared by aerosol assisted CVD. RSC Adv 7:10806–10814. https://doi.org/10.1039/c6ra27748a

Hou X, Choy KL (2006) Processing and applications of aerosol-assisted chemical vapor deposition. Chem Vap Depos 12:583–596. https://doi.org/10.1002/cvde.200600033

Filho PIO, Carmalt CJ, Angeli P, Fraga ES (2020) Mathematical modeling for the design and scale-up of a large industrial aerosol-assisted chemical vapor deposition process under uncertainty. Ind Eng Chem Res 59:1249–1260. https://doi.org/10.1021/acs.iecr.9b05869

Hussain SM, Sadullah M, Ghosh K (2023) Aerosol-assisted CVD of nickel oxide on silicon for hole selective contact layers. J Mater Sci Mater Electron 34:1–10. https://doi.org/10.1007/s10854-022-09547-1

Kadari A, Schemme T, Kadri D, Wollschläger J (2017) XPS and morphological properties of Cr2O3 thin films grown by thermal evaporation method. Results Phys 7:3124–3129. https://doi.org/10.1016/j.rinp.2017.08.036

Sadullah M, Hussain SM, Ghosh K (2023) Mist CVD-based growth of crystalline alpha chromium oxide (α-Cr2O3) on c-plane sapphire substrate with chromium acetylacetonate as a precursor. Chem Pap. https://doi.org/10.1007/s11696-023-02920-2

Bumajdad A, Al-Ghareeb S, Madkour M, Al SF (2017) Non-noble, efficient catalyst of unsupported α-Cr2O3 nanoparticles for low temperature CO Oxidation. Sci Rep 7:2–10. https://doi.org/10.1038/s41598-017-14779-x

Hassel M, Freund H-J (1996) High Resolution XPS Study of a Thin CoO(111) Film Grown on Co(0001). Surf Sci Spectra 4:273–278. https://doi.org/10.1116/1.1247797

Singh J, Verma V, Kumar R et al (2019) Corrigendum: Effect of structural and thermal disorder on the optical band gap energy of Cr2O3 nanoparticles. Mater Res Express 6:085039. https://doi.org/10.1088/2053-1591/ab308a

Abdullah MM, Rajab FM, Al-Abbas SM (2014) Structural and optical characterization of Cr2O3 nanostructures: evaluation of its dielectric properties. AIP Adv 4. https://doi.org/10.1063/1.4867012

Zahra ST, Syed WAA, Rafiq N et al (2021) On structural, optical, and electrical properties of chromium oxide Cr2O3 thin film for applications. Prot Met Phys Chem Surf 57:321–328. https://doi.org/10.1134/S2070205121010238

Islam T, Jani R, Islam AF et al (2021) Investigation of CsSn0.5Ge0.5I3-on-Si Tandem Solar Device Utilizing SCAPS Simulation. IEEE Trans Electron Devices 68(2):618–625. https://doi.org/10.1109/TED.2020.3045383

Acknowledgements

This work was supported by the Centre for Design & Fabrication of Electronic Devices (C4DFED) and Advanced Materials Research Centre (AMRS) of IIT Mandi.

Author information

Authors and Affiliations

Contributions

Md. Sadullah: Contributed towards performing the experiments and analysis of the results obtained through scanning electron microscopy and atomic force microscopy. He also contributed to the fabrication, numerical simulation, and analysis of the diodes.

Syed Md. Hussain: Contributed to the analysis of the XPS results.

Kunal Ghosh: Contributed to the design and supervision of the study.

The first draft of the manuscript was prepared by Md. Sadullah. All the authors contributed to the necessary revisions and preparing the final draft.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

We consent for the publication of our work.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sadullah, M., Hussain, S.M. & Ghosh, K. Growth of Cr2O3 on n-Silicon Substrate using AACVD and its Application as a Hole Selective Layer. Silicon 16, 1893–1903 (2024). https://doi.org/10.1007/s12633-023-02791-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02791-y