Abstract

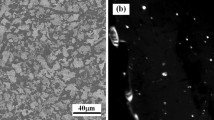

The characteristics of nanosized precipitates in steels depend on the heat-treatment parameters. The effects of characteristics of vanadium precipitates formed during isothermal heat treatment on the hardness of the ferrite matrix in low-carbon vanadium-alloyed steel were investigated through analysis of transmission electron microscopy images and microhardness measurements. The results show that, during isothermal holding in the temperature range from 675 to 750°C, only interphase precipitation occurs, whereas only random precipitation occurs in the ferrite matrix during holding at 600°C. Furthermore, during isothermal heat treatment between 600 and 675°C, both random and interphase precipitates occurred in the ferrite. Nanoscale vanadium carbides with different atomic ratios of vanadium (V) and carbon (C) were the dominant precipitates in the random and interphase precipitates. The sizes of random precipitation carbides were smaller than those of interphase ones. Also, the sample isothermally heat treated at 650°C for 900 s exhibited a higher hardness with a narrower hardness distribution.

Similar content being viewed by others

References

A.T.W. Barrow and P.E.J. Rivera-Diaz-del-Castillo, Nanoprecipitation in bearing steels, Acta Mater., 59(2011), No. 19, p. 7155.

H.L. Yi, Y. Xu, M.X. Sun, Z.Y. Liu, and G.D. Wang, Influence of finishing cooling temperature and holding time on nanometer-size carbide of Nb-Ti microalloyed steel, J. Iron Steel Res. Int., 21(2014), No. 4, p. 433.

T.P. Wang, F.H. Kao, S.H. Wang, J.R. Yang, C.Y. Huang, and H.R. Chen, Isothermal treatment influence on nanometer-size carbide precipitation of titanium-bearing low carbon steel, Mater. Lett., 65(2011), No. 2, p. 396.

G. Miyamoto, H. Ryota, T. Poorganji, and T. Furuhara, Interphase precipitation of VC and resultant hardening in V-added medium carbon steels, ISIJ Int., 51(2011), No. 10, p. 1733.

C.Y. Chen, C.C. Chen, and J.R. Yang, Microstructure characterization of nanometer carbides heterogeneous precipitation in Ti–Nb and Ti–Nb–Mo steel, Mater. Charact., 88(2014), p. 69.

Y. Funakawa, T. Shiozaki, K. Tomita, T. Yamamoto, and E. Maeda, Development of high strength hot-rolled sheet steel consisting of ferrite and nanometer-sized carbides, ISIJ Int., 44(2004), No. 11, p. 1945.

N. Kamikawa, K. Sato, G. Miyamoto, M. Murayama, N. Sekido, K. Tsuzakie, and T. Furuhara, Stress–strain behavior of ferrite and bainite with nano-precipitation in low carbon steels, Acta Mater., 83(2015), p. 383.

T.N. Baker, Processes, microstructure and properties of vanadium microalloyed steels, Mater. Sci. Technol., 25(2009), No. 9, p. 1083.

C.Y. Chen, S.F. Chen, C.C. Chen, and J.R. Yang, Control of precipitation morphology in the novel HSLA steel, Mater. Sci. Eng. A, 634(2015), p. 123.

C.Y. Chen, H.W. Yen, F.H. Kao, W.C. Li, C.Y. Huang, J.R. Yang, and S.H. Wang, Precipitation hardening of high-strength low-alloy steels by nanometer-sized carbides, Mater. Sci. Eng. A, 499(2009), No. 1-2, p. 162.

Q.Y. Sha, G.Y. Li, L.F. Qiao, and P.Y. Yan, Effect of cooling rate and coiling temperature on precipitate in ferrite of Nb-V-Ti microalloyed strip steel, J. Iron Steel Res. Int., 14(2007), No. 5, p. 316.

R. Lagneborg and S. Zajac, A model for interphase precipitation in V-microalloyed structural steels, Metall. Mater. Trans. A, 32(2001), No. 1, p. 39.

T. Epicier, D. Acevedo, and M. Perez, Crystallographic structure of vanadium carbide precipitates in a model Fe-C-V steel, Philos. Mag., 88(2008), No. 1, p. 31.

F.A. Khalid and D.V. Edmonds, Interphase precipitation in microalloyed engineering steels and model alloy, Mater. Sci. Technol., 9(1993), No. 5, p. 384.

M.M.A. Bepari, Effects of precipitates on strength and toughness of vanadium structural steels, Mater. Sci. Technol., 6(1990), No. 4, p. 338.

A. Barbacki and R.W.K. Honeycombe, Transition in carbide morphology in molybdenum and vanadium steels, Metallography, 9(1976), No. 4, p. 277.

C.Y. Chen, C.C. Chen, and J.R. Yang, Dualism of precipitation morphology in high strength low alloy steel, Mater. Sci. Eng. A, 626(2015), p. 74.

M.Y. Chen, M. Gouné, M. Verdier, Y. Bréchet, and J.R. Yang, Interphase precipitation in vanadium-alloyed steels: Strengthening contribution and morphological variability with austenite to ferrite transformation, Acta Mater., 64(2014), p. 78.

R.M. Smith and D.P. Dunne, Structure aspects of alloy carbonitrides precipitation on microalloyed steels, Mater. Forum, 11(1988), p. 166.

M. Nöhrer, S. Zamberger, S. Primig, and H. Leitner, Atom probe study of vanadium interphase precipitates and randomly distributed vanadium precipitates in ferrite, Micron, 54-55(2013), p. 57.

Y.J. Zhang, G. Miyamoto, K. Shinbo, T. Furuhara, T. Ohmura, T. Suzuki, and K. Tsuzaki, Effects of transformation temperature on VC interphase precipitation and resultant hardness in low-carbon steels, Acta Mater., 84(2015), p. 375.

T. Murakami, H. Hatano, G. Miyamoto, and T. Furuhara, Effects of ferrite growth rate on interphase boundary precipitation in V microalloyed steels, ISIJ Int., 52(2012), No. 4, p. 616.

Y.J. Zhang, G. Miyamoto, K. Shinbo, and T. Furuhara, Effects of α/γ orientation relationship on VC interphase precipitation in low-carbon steels, Scripta Mater., 69(2013), No. 1, p. 17.

H.W. Yen, P.Y. Chen, C.Y. Huang, and J.R. Yang, Interphase precipitation of nanometer-sized carbides in a titanium–molybdenum-bearing low-carbon steel, Acta Mater., 59(2011), No. 16, p. 6264.

Acknowledgements

One of the authors (Sayed Ghafar Hashemi) wants to express his heartfelt appreciation to Mr. G. Etzlstorfer from the Voestalpine Steel Division and Dr. M. Alaei, for providing the opportunity to conduct experiments in Graz, Austria. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hashemi, S.G., Eghbali, B. Analysis of the formation conditions and characteristics of interphase and random vanadium precipitation in a low-carbon steel during isothermal heat treatment. Int J Miner Metall Mater 25, 339–349 (2018). https://doi.org/10.1007/s12613-018-1577-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-018-1577-8