Abstract

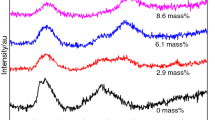

To elucidate the behavior of slag films in an electroslag remelting process, the fluoride evaporation and crystallization of CaF2–CaO–Al2O3–(TiO2) slags were studied using the single hot thermocouple technique. The crystallization mechanism of TiO2-bearing slag was identified based on kinetic analysis. The fluoride evaporation and incubation time of crystallization in TiO2-free slag are found to considerably decrease with decreasing isothermal temperature down to 1503 K. Fish-bone and flower-like CaO crystals precipitate in TiO2-free slag melt, which is accompanied by CaF2 evaporation from slag melt above 1503 K. Below 1503 K, only near-spherical CaF2 crystals form with an incubation time of less than 1 s, and the crystallization is completed within 1 s. The addition of 8.1wt% TiO2 largely prevents the fluoride evaporation from slag melt and promotes the slag crystallization. TiO2 addition leads to the precipitation of needle-like perovskite (CaTiO3) crystals instead of CaO crystals in the slag. The crystallization of perovskite (CaTiO3) occurs by bulk nucleation and diffusion-controlled one-dimensional growth.

Similar content being viewed by others

References

C.B. Shi, J. Li, J.W. Cho, F. Jiang, and I.H. Jung, Effect of SiO2 on the crystallization behaviors and in-mold performance of CaF2–CaO–Al2O3 slags for drawing-ingot-type electroslag remelting, Metall. Mater. Trans. B, 46(2015), No. 5, p. 2110.

X.C. Lu, Effect of titanium on surface formability of ESR super alloy ingot, Foundry, 51(2002), No. 6, p. 378.

A. Choudhury, State of the art of superalloy production for aerospace and other application using VIM/VAR or VIM/ESR, ISIJ Int., 32(1992), No. 5, p. 563.

W. Li, W. Wang, Y. Hu, and Y. Chen, The estimation and control of the electroslag remelting melt rate by mechanism-based modeling, Metall. Mater. Trans. B, 43(2012), No. 2, p. 276.

Y.B. Li, J.X. Zhao, W.D. Tang, Y.M. Dang, S.T. Qiu, and Y.R. Cui, Composition and structure of slag shell during electroslag remelting process with CaF2-Al2O3-CaO slag series, Spec. Steel, 35(2014), No. 4, p. 28.

Y. Kashiwaya, C.E. Cicutti, A.W. Cramb, and K. Ishii, Development of double and single hot thermocouple technique for in situ observation and measurement of mold slag crystallization, ISIJ Int., 38(1998), No. 4, p. 348.

L. Zhou, W. Wang, D. Huang, J. Wei, and J. Li, In situ observation and investigation of mold flux crystallization by using double hot thermocouple technology, Metall. Mater. Trans. B, 43(2012), No. 4, p. 925.

J. Yang, Y. Cui, L. Wang, Y. Sasaki, J. Zhang, O. Ostrovski, and Y. Kashiwaya, In-situ study of crystallization behavior of a mold flux using single and double hot thermocouple technique, Steel Res. Int., 86(2015), No. 6, p. 636.

J. Gao, G. Wen, Q. Sun, P. Tang, and Q. Liu, The influence of Na2O on the solidification and crystallization behavior of CaO–SiO2–Al2O3-based mold flux, Metall. Mater. Trans. B, 46(2015), No. 4, p. 1850.

Y. Sugiyama, R. Chiba, S. Fujimori, and N. Funakoshi, Crystallization process of In–Te alloy films for optical recording, J. Non Cryst. Solids, 122(1990), No. 1, p. 83.

E. Kinsbron, M. Sternheim, and R. Knoell, Crystallization of amorphous silicon films during low pressure chemical vapor deposition, Appl. Phys. Lett., 42(1983), No. 9, p. 835.

V. Weidenhof, I. Friedrich, S. Ziegler, and M. Wuttig, Laser induced crystallization of amorphous Ge2Sb2Te5 films, J. Appl. Phys., 89(2001), No. 6, p. 3168.

V.D. Eisenhüttenleute, Slag Atlas, 2nd ed., Woodhead Publishing Limited, Cambridge, 1995, p. 191.

M. Shinmei and T. Machida, Vaporization of AlF3 from the slag CaF2–Al2O3, Metall. Trans., 4(1973), No. 8, p. 1996.

M. Persson, S. Seetharaman, and S. Seetharaman, Kinetic studies of fluoride evaporation from slags, ISIJ Int., 47(2007), No. 12, p. 1711.

Z. Zhang, G. Wen, P. Tang, and S. Sridhar, The influence of Al2O3/SiO2 ratio on the viscosity of mold fluxes, ISIJ Int., 48(2008), No. 6, p. 739.

F. Shahbazian, D. Sichen, and S. Seetharaman, Viscosities of some fayalitic slags containing CaF2, ISIJ Int., 39(1999), No. 7, p. 687.

F. Shahbazian, D. Sichen, and S. Seetharaman, The effect of addition of Al2O3 on the viscosity of CaO–FeO–SiO2–CaF2 slags, ISIJ Int., 42(2002), No. 2, p. 155.

C.B. Shi, Behaviour and Control Technique of Oxygen and Inclusions during Protective Gas Electroslag Remelting Process [Dissertation], University of Science and Technology Beijing, Beijing, 2013, p. 8.

J.W.P. Schmelzer, Nucleation Theory and Applications, Wiley-VCH, Weinheim, 2005, p. 413.

J.Y. Park, J.W. Ryu, and I. Sohn, In-situ crystallization of highly volatile commercial mold flux using an isolated observation system in the confocal laser scanning microscope, Metall. Mater. Trans. B, 45(2014), No. 4, p. 1186.

M.D. Seo, C.B. Shi, J.W. Cho, and S.H. Kim, Crystallization behaviors of CaO–SiO2–Al2O3–Na2O–CaF2–(Li2O–B2O3) mold fluxes, Metall. Mater. Trans. B, 45(2014), No. 5, p. 1874.

G.H. Zhang, K.C. Chou, Q.G. Xue, and K.C. Mills, Modeling viscosities of CaO–MgO–FeO–MnO–SiO2 molten slags, Metall. Mater. Trans. B, 43(2012), No. 1, p. 64.

G.H. Zhang, K.C. Chou, and K. Mills, Modelling viscosities of CaO–MgO–Al2O3–SiO2 molten slags, ISIJ Int., 52(2012), No. 3, p. 355.

G.H. Zhang, K.C. Chou, and K. Mills, A structurally based viscosity model for oxide melts, Metall. Mater. Trans. B, 45(2014), No. 2, p. 698.

W. Höland and G.H. Beall, Glass Ceramic Technology, 2nd Ed., John Wiley & Sons, Inc., Hoboken, New Jersey, 2012, p. 46.

K. Matusita, T. Komatsu, and R. Yokota, Kinetics of non-isothermal crystallization process and activation energy for crystal growth in amorphous materials, J. Mater. Sci., 19(1984), No. 1, p. 291.

J. Farjas and P. Roura, Modification of the Kolmogorov-Johnson–Mehl–Avrami rate equation for non-isothermal experiments and its analytical solution, Acta Mater., 54(2006), No. 20, p. 5573.

M.M. Kržmanc, U. Došler, and D. Suvorov, Effect of a TiO2 nucleating agent on the nucleation and crystallization behavior of MgO–B2O3–SiO2 glass, J. Am. Ceram. Soc., 95(2012), No. 6, p. 1920.

G. Carl, T. Höche, and B. Voigt, Crystallisation behaviour of a MgO–Al2O3–SiO2–TiO2–ZrO2 glass, Phys. Chem. Glasses, 43C(2002), p. 256.

J.L. Li, Q.F. Shu, and K.C. Chou, Effect of TiO2 addition on viscosity and structure of CaO–Al2O3 based mould fluxes for high Al steel casting, Can. Metall. Q., 54(2015), No. 1, p. 85.

M. Avrami, Kinetics of phase change: I. General theory, J. Chem. Phys., 7(1939), No. 12, p. 1103.

W.A. Johnson and K.F. Mehl, Reaction kinetics in processes of nucleation and growth, Trans. Am. Inst. Min. Metall. Eng., 135(1939), p. 416.

M. Avrami, Kinetics of phase change: II. Transformation–time relations for random distribution of nuclei, J. Chem. Phys., 8(1940), p. 212.

M. Avrami, Granulation, phase change, and microstructure kinetics of phase change: III, J. Chem. Phys., 9(1941), p. 177.

M.D. Seo, C.B. Shi, J.Y. Baek, J.W. Cho, and S.H. Kim, Kinetics of isothermal melt crystallization in CaO–SiO2–CaF2-based mold fluxes, Metall. Mater. Trans. B, 46(2015), No. 5, p. 2374.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shi, Cb., Cho, Jw., Zheng, Dl. et al. Fluoride evaporation and crystallization behavior of CaF2–CaO–Al2O3–(TiO2) slag for electroslag remelting of Ti-containing steels. Int J Miner Metall Mater 23, 627–636 (2016). https://doi.org/10.1007/s12613-016-1275-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1275-3