Abstract

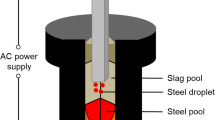

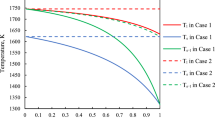

TiN inclusions observed in an ingot produced by electroslag remelting (ESR) are extremely harmful to GCr15SiMn steel. Therefore, accurate predictions of the growth size of these inclusions during steel solidification are significant for clean ESR ingot production. On the basis of our previous work, a coupled model of solute microsegregation and TiN inclusion growth during solidification has been established. The results demonstrate that compared to a non-coupled model, the coupled model predictions of the size of TiN inclusions are in good agreement with experimental results using scanning electron microscopy with energy disperse spectroscopy (SEM-EDS). Because of high cooling rate, the sizes of TiN inclusions in the edge area of the ingots are relatively small compared to the sizes in the center area. During the ESR process, controlling the content of Ti in the steel is a feasible and effective method of decreasing the sizes of TiN inclusions.

Similar content being viewed by others

References

X.N. Yang, G.G. Cheng, M.L. Wang, Y.L. Li, Y.G. Wang, and P. Zhao, Precipitation and growth of titanium nitride during solidification of clean steel, J. Univ. Sci. Technol. Beijing, 10(2003), No. 5, p. 24.

W.J. Ma, Y.P. Bao, L.H. Zhao, and M. Wang, Control of the precipitation of TiN inclusions in gear steels, Int. J. Miner. Metall. Mater., 21(2014), No. 3, p. 234.

H. Goto, K.I. Miyazawa, W. Yamada, and K. Tanaka, Effect of cooling rate on composition of oxides precipitated during solidification of steels, ISIJ Int., 35(1995), No. 6, p. 708.

Y.D. Jiang, Z.L. Xue, J. Wu, M.W. Gui, and Y.F. Zheng, Thermodynamics and dynamics of TiN precipitation during solidification of steel 82A, J. Wuhan. Univ. Sci. Technol., 33(2010), No. 4, p. 358.

Z.Z. Liu, J. Wei, and K.K. Cai, A coupled mathematical model of microsegregation and inclusion precipitation during solidification of silicon steel, ISIJ Int., 42(2002), No. 9, p. 958.

H.Q. Zhang, S.B. Zheng, Q. Zheng, Z.L. Liu, and G.H. Jiang, A coupled model of microsegregation and Ti-O inclusion precipitation during solidification of liquid steel, Acta Metall. Sin., 42(2006), No. 7, p. 745.

L. Yang, S.J. Li, G.G. Cheng, M. Zhao, and G.P. Feng, A coupled model of microsegregation and TiN inclusion precipitation during solidification of GCr15SiMn in ESR Process, [in] Materials Science and Technology 2014, Pittsburgh, 2014, p. 379.

X.Z. Tian, R.Z. Liu, C.F. Zhou, Z.X. Xue, and B.J. Zhong, Control of titanium nitride in bearing steel, J. Univ. Sci. Technol. Beijing, 31(2009), Suppl. 1, p. 150.

J. Fu, J. Zhu, L. Di, F.S. Tong, D.L. Lu, and Y.L. Wang, Study on the precipitation behavior of TiN in the microalloyed steels, Acta Metall. Sin., 36(2000), No. 8, p. 801.

J.Y. Zhang, Physical Chemistry of Metallurgy, Metallurgical Industry Press, Beijing, 2009, p. 200.

M. Wang, Y.P. Bao, H. Cui, H.J. Wu, and W.S. Wu, Generation mechanism of Al2O3-TiN inclusion in IF steel, J. Iron Steel Res., 22(2010), No. 7, p. 29.

J.X. Chen, Manual of Chart and Data in Common Use of Steel Making, 2nd Ed., Metallurgical Industry Press, Beijing, 2010, p. 510.

Z. Ma and D. Janke, Characteristics of oxide precipitation and growth during solidification of deoxidized steel, ISIJ Int., 38(1998), No. 1, p. 46.

I. Ohnaka, Mathematical analysis of solute redistribution during solidification with diffusion in solid phase, Trans. Iron Steel Inst. Jpn., 26(1986), No. 12, p. 1045.

S.K. Choudhary and A. Ghosh, Mathematical model for prediction of composition of inclusions formed during solidification of liquid steel, ISIJ Int., 49(2009), No. 12, p. 1819.

L. Yang, S.J. Li, G.G. Cheng, M. Zhao, and G.P. Feng, Generation mechanism of TiN inclusion for GCr15SiMn during electroslag remelting process, ISIJ Int., 55(2015), No. 9, p. 1901.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Cheng, Gg., Li, Sj. et al. A coupled model of TiN inclusion growth in GCr15SiMn during solidification in the electroslag remelting process. Int J Miner Metall Mater 22, 1266–1272 (2015). https://doi.org/10.1007/s12613-015-1194-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-015-1194-8