Abstract

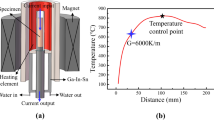

The dynamic recrystallization (DRX) behavior of continuous columnar-grained (CCG) CuNi10Fe1Mn alloy was investigated by hot compression along the solidification direction (SD) and perpendicular to the solidification direction (PD). Specimens were compressed to a true strain of 0.8 at temperatures ranging from 25°C to 900°C and strain rates ranging from 0.01 to 10 s−1. The results indicate that DRX nucleation at grain boundaries (GBs) and DRX nucleation at slip bands (SBs) are the two main nucleation modes. For SD specimens, C-shaped bending and zig-zagging of the GBs occurred during hot compression, which made DRX nucleation at the GBs easier than that at the SBs. When lnZ ≤ 37.4 (Z is the Zener–Hollomon parameter), DRX can occur in SD specimens with a critical temperature for the DRX onset of ~650°C and a thermal activated energy (Q) of 313.5 kJ·mol−1. In contrast, in PD specimens, the GBs remained straight, and DRX nucleation occurred preferentially at the SBs. For PD specimens, the critical temperature is about 700°C, Q is 351.7 kJ·mol−1, and the occurrence condition of DRX is lnZ ≤ 40.1. The zig-zagging of GB morphology can significantly reduce the nucleation energy at the GBs; as a result, DRX nucleation occurs more easily in SD specimens than in PD specimens.

Similar content being viewed by others

References

J.X. Xie, Advanced Processing Technologies of Materials, Metallurgical Industry Press, Beijing, 2004, p. 83.

J.X. Xie, Y. Wang, and H.Y. Huang, Extreme plastic extensibility and ductility improvement mechanisms of continuous columnar-grained copper and copper alloys, Chin. J. Nonferrous Met., 21(2011), No. 10, p. 2324.

T.J. Glover, Copper-nickel alloy for the construction of ship and boat hulls, Br. Corros. J., 17(1982), No. 4, p. 155.

Y.B. Fu, Z.M. Yan, T.J. Li, P. Chen, Y.F. Cheng, and G.M. Yin, Study on plastic behaviours of CuNi10Fe1Mn alloy tubes under cast-roll process, Mater. Des., 30(2009), No. 10, p. 4478.

J.X. Xie, J. Mei, X.H. Liu, and X.F. Liu, A Kind of Process and Equipment for Fabricating Cupronickel Pipes with Heating–Cooling Combined Mold Casting, Chinese Patent, Appl. CN201010501407.4, 2011.

J. Mei, X.H. Liu, and J.X. Xie, Microstructure and mechanical properties of BFe10 cupronickel alloy tubes fabricated by a horizontal continuous casting with heating-cooling combined mold technology, Int. J. Miner. Metall. Mater., 19(2012), No. 4, p. 339.

Y.K. Liu, H.Y. Huang, and J.X. Xie, Anisotropic deformation behavior of continuous columnar-grained CuNi10Fe1Mn alloy, Acta Metall. Sin., 51(2014), No. 1, p. 40.

H. Zhang, Fundamental Research on Fabrication for Pure Copper Wires Containing Fibrous Crystals [Dissertation], University of Science and Technology Beijing, Beijing, 2003, p. 66.

J.W. Yu, X.F. Liu, and J.X. Xie, Study of dynamic recrystallization of a Cu-based alloy BFe10-1-1 with continuous columnar grains, Acta Metall. Sin., 47(2011), No. 4, p. 482.

C.M. Sellars and W.J. McTegart, On the mechanism of hot deformation, Acta Metall., 14(1966), No. 9, p. 1136.

C. Zener and J.H. Hollomon, Effect of strain rate upon plastic flow of steel, J. Appl. Phys., 15(1944), No. 1, p. 22.

X.N. Peng, H.Z. Guo, Z.F. Shi, C. Qin, and Z.L. Zhao, Constitutive equations for high temperature flow stress of TC4-DT alloy incorporating strain, strain rate and temperature, Mater. Des., 50(2013), p. 198.

H.J. McQueen and N.D. Ryan, Constitutive analysis in hot working, Mater. Sci. Eng. A, 322(2002), No. 1-2, p. 43.

H.L. Wei, G.Q. Liu, X. Xiao, and M.H. Zhang, Apparent and physically based constitutive analyses for hot deformation of austenite in 35Mn2 steel, Acta Metall. Sin., 49(2013), No. 6, p. 731.

N.P. Jin, H. Zhang, Y. Han, W.X. Wu, and J.H. Chen, Hot deformation behavior of 7150 aluminum alloy during compression at elevated temperature, Mater. Charact., 60(2009), No. 6, p. 530.

M. Jafari and A. Najafizadeh, Correlation between Zener-Hollomon parameter and necklace DRX during hot deformation of 316 stainless steel, Mater. Sci. Eng. A, 501(2009), No. 1-2, p. 16.

H. Miura, T. Sakai, H. Hamaji, and J.J. Jonas, Preferential nucleation of dynamic recrystallization at triple junctions, Scripta Mater., 50(2004), No. 1, p. 65.

H. Miura, H. Aoyama. and T. Sakai, Effect of grain-boundary misorientation on dynamic recrystallization of Cu–Si bicrystals, J. Jpn. Inst. Met., 58(1994), No. 3, p. 267.

H. Miura, M. Ozama, R. Mogawa, and T. Sakai, Strain-rate effect on dynamic recrystallization at grain boundary in Cu alloy bicrystal, Scripta Mater., 48(2003), No. 10, p. 1501.

D. Ponge and G. Gottstein, Necklace formation during dynamic recrystallization: mechanisms and impact on flow behavior, Acta Mater., 46(1998), No. 1, p. 69.

A.M. Wusatowska-Sarnek, H. Miura, and T. Sakai, Nucleation and microtexture development under dynamic recrystallization of copper, Mater. Sci. Eng. A, 323(2002), No. 1-2, p. 177.

A. Belyakov, H. Miura, and T. Sakai, Dynamic recrystallization under warm deformation of a 304 type austenitic stainless steel, Mater. Sci. Eng. A, 255(1998), No. 1-2, p. 139.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Yk., Huang, Hy. & Xie, Jx. Effect of compression direction on the dynamic recrystallization behavior of continuous columnar-grained CuNi10Fe1Mn alloy. Int J Miner Metall Mater 22, 851–859 (2015). https://doi.org/10.1007/s12613-015-1142-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-015-1142-7