Abstract

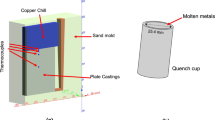

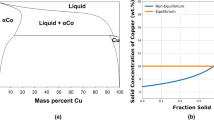

In the modeling of microsegregation, the partition coefficient is usually calculated using data from the equilibrium phase diagrams. The aim of this study was to experimentally and theoretically analyze the partition coefficient in binary aluminum-copper alloys. The samples were analyzed by differential thermal analysis (DTA), which were melted and quenched from different temperatures during solidification. The mass fraction and composition of phases were measured by image processing and scanning electron microscopy (SEM) equipped with an energy-dispersive X-ray spectroscopy (EDS) unit. These data were used to calculate as the experimental partition coefficients with four different methods. The experimental and equilibrium partition coefficients were used to model the concentration profile in the primary phase. The modeling results show that the profiles calculated by the experimental partition coefficients are more consistent with the experimental profiles, compared to those calculated using the equilibrium partition coefficients.

Similar content being viewed by others

References

D. H. Kirkwood, Microsegregation, Mater. Sci. Eng. A, 65(1984), No. 1, p. 101.

I. Ohnaka, Mathematical analysis of solute redistribution during solidification with diffusion in solid phase, Trans. ISIJ, 26(1986), No. 26, p. 1045.

S. Kobayashi, Solute redistribution during solidification with diffusion in solid phase: a theoretical analysis, J. Cryst. Growth, 88(1988), No. 1, p. 87.

T. Kraft, M. Rettenmayr, and H.E. Exner, An extended numerical procedure for predicting microstructure and microsegregation of multicomponent alloys, Modell. Simul. Mater. Sci. Eng., 4(1996), No. 2, p. 161.

X. Doré, H. Combeau, and M. Rappaz, Modelling of microsegregation in ternary alloys: application to the solidification of Al-Mg-Si, Acta Mater., 48(2000), No. 15, p. 3951.

Q. Du and A. Jacot, A two-dimensional microsegregation model for the description of microstructure formation during solidification in multicomponent alloys: Formulation and behavior of the model, Acta Mater., 53(2005), No. 12, p. 3479.

A. Turkeli, Approximate analytical models for microsegregation considering the effect of dendrite arm coarsening, Mater. Sci. Forum, 508(2006), p. 449.

S.N. Samaras and G.N. Haidemenopoulos, Modelling of microsegregation and homogenization of 6061 extrudable Al-alloy, J. Mater. Process. Technol., 194(2007), No. 1–3, p. 63.

Q. Du, D.G. Eskin, A. Jacot, and L. Katgerman, Two-dimensional modelling and experimental study on microsegregation during solidification of an Al-Cu binary alloy, Acta Mater., 55(2007), No. 5, p. 1523.

G. Kasperovich, T. Volkmann, L. Ratke, and D. Herlach, Microsegregation during solidification of an Al-Cu binary alloy at largely different cooling rates (0.01 to 20,000 K/s): modeling and experimental study, Metall. Mater. Trans. A, 39(2008), No. 5, p. 1183.

J. Tang and X. Xue, Numerical simulation of multi-grain structure and prediction of microsegregation in binary Ni-Cu alloy under isothermal conditions, Mater. Sci. Eng. A, 499(2009), No. 1–2, p. 64.

T.P. Battle, Mathematical modelling of solute segregation in solidifying materials, Int. Mater. Rev., 37(1992), No. 6, p. 249.

H. Fredriksson and U. Akerlind, Solidification and Crystallization Processing in metals and Alloys, John Wiley & Sons, Chichester, West Sussex, 2012, p. 475.

F.Y. Xie, T. Kraft, Y. Zuo, C.H. Moon, and Y.A. Chang, Mi crostructure and microsegregation in Al-rich Al-Cu-Mg alloys, Acta Mater., 47(1999), No. 2, p. 489.

H. Liang, T. Kraft, and Y.A. Chang, Importance of reliable phase equilibria in studying microsegregation in alloys: Al-Cu-Mg, Mater. Sci. Eng. A, 292(2000), No. 1, p. 96.

X.Y. Yan, F.Y. Xie, M. Chu, and Y.A. Chang, Microsegregation in Al-4.5Cu wt.% alloy: experimental investigation and numerical modeling, Mater. Sci. Eng. A, 302(2001), No. 2, p. 268.

E.C. Kurum, H.B. Dong, and J.D. Hunt, Microsegregation in Al-Cu alloys, Metall. Mater. Trans. A, 36(2005), No. 11, p. 3103.

M.N. Gungor, A statistically significant experimental technique for investigating microsegregation in cast alloys, Metall. Trans. A, 20(1989), No. 11, p. 2529.

J. Valdes, S.L. Shang, Z.K. Liu, P. King, and X.B. Liu, Quenching differential thermal analysis and thermodynamic calculation to determine partition coefficients of solute elements in simplified Ni-base superalloys, Metall. Mater. Trans. A, 41(2010), No. 2, p. 487.

W.F. Gale and T.C. Totemeier, Smithells Metals Reference Book, Elsevier, Burlington, 2004, p. 13.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Avazkonandeh-Gharavol, M.H., Haddad-Sabzevar, M. & Fredriksson, H. Effect of partition coefficient on microsegregation during solidification of aluminium alloys. Int J Miner Metall Mater 21, 980–989 (2014). https://doi.org/10.1007/s12613-014-0999-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0999-1