Abstract

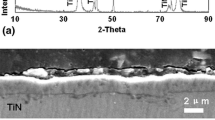

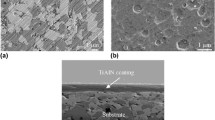

Monolayer and bilayer coatings of TiAlN, AlCrN, and AlCrN/TiAlN were deposited onto tungsten carbide inserts using the plasma enhanced physical vapor deposition process. The microstructures of the coatings were characterized using scanning electron microscopy (SEM) and atomic force microscopy (AFM). The SEM micrographs revealed that the AlCrN and AlCrN/TiAlN coatings were uniform and highly dense and contained only a limited number of microvoids. The TiAlN coating was non-uniform and highly porous and contained more micro droplets. The hardness and scratch resistance of the specimens were measured using a nanoindentation tester and scratch tester, respectively. Different phases formed in the coatings were analyzed by X-ray diffraction (XRD). The AlCrN/TiAlN coating exhibited a higher hardness (32.75 GPa), a higher Young’s modulus (561.97 GPa), and superior scratch resistance (L CN = 46 N) compared to conventional coatings such as TiAlN, AlCrN, and TiN.

Similar content being viewed by others

References

M. Soković, Quality management in development of hard coatings on cutting tools, J. Achiev. Mater. Manuf. Eng., 24(2007), No. 1, p. 421.

L.A. Dobrzański, K. Lukaszkowicz, and K. Labisz, Structure, texture and chemical composition of coatings deposited by PVD techniques, Arch. Mater. Sci. Eng., 37(2009), No. 1, p. 45.

C. Chokwatvikul, S. Larpkiattaworn, S. Surinphong, C. Busabok, and P. Termsuksawad, Effect of nitrogen partial pressure on characteristic and mechanical properties of hard coating TiAlN film, J. Met., Mater. Miner., 21(2011), No. 1, p. 115.

LA. Dobrzański, M. Staszuk, K. Golombek, and M. Pancielejko, Properties of Ti(B,N) coatings deposited onto cemented carbides and sialon tool ceramics, J. Achiev. Mater. Manuf. Eng., 41(2010), No. 1–2, p. 66.

A. Knutsson, M.P. Johansson, L. Karlsson, and M. Odén, Thermally enhanced mechanical properties of arc evaporated Ti0.34Al0.66N/TiN multilayer coatings, J. Appl. Phys., 108(2010), art. No. 044312.

A.D. Korotaev, D.P. Borisov, V.Yu. Moshkov, S.V. Ovchinnikov, K.V. Oskomov, Yu.P. Pinzhin, V.M. Savostikov, and A.N. Tymentsev, Nanocomposite and nanostructured superhard Ti-Si-B-N coatings, Russ. Phys. J., 50(2007), No. 10, p. 969.

V. Chawla, A. Chawla, Y. Mehta, D. Puri, S. Prakash, and B.S. Sidhu, Investigation of properties and corrosion behavior of hard TiAlN and AlCrN PVD thin coatings in the 3 wt% NaCl solution, J. Aust. Ceram. Soc., 47(2011), No. 1, p. 48.

S. Veprek, S. Mukherjee, H.D. Männling, and J.L. He, On the reliability of the measurements of mechanical properties of superhard coatings, Mater. Sci. Eng. A, 340(2003), p. 292.

G. Cabrera, F. Torres, J.C. Caicedo, W. Aperador, C. Amaya, and P. Prieto, Improvement of electrochemical surface properties in steel substrates using a nanostructured CrN/AlN multilayer coating, J. Mater. Eng. Perform., 21(2012), p. 128.

Y.Y. Chang, D.Y. Wang, and C.Y. Hung, Structural and mechanical properties of nanolayered TiAlN/CrN coatings synthesized by a cathodic arc deposition process, Surf. Coat. Technol., 200(2005), p. 1702.

S. Zhang, D. Sun, Y.Q. Fu, and H.J. Du, Recent advances of superhard nanocomposite coatings: a review, Surf. Coat. Technol., 167(2003), p. 113.

G.S. Fox-Rabinovich, K. Yamamoto, M.H. Aguirre, D.G. Cahill, S.C. Veldhuis, A. Biksa, G. Dosbaeva, and L.S. Shuster, Multi-functional nano-multilayered AlTiN/Cu PVD coating for machining of Inconel 718 superalloy, Surf. Coat. Technol., 204(2010), p. 2465.

M. Polok-Rubiniec, L.A. Dobrzański, K. Lukaszhowicz, and M. Adamiak, Comparison of the structure, properties and wear resistance of the TiN PVD coatings, J. Achiev. Mater. Manuf. Eng., 27(2008), No. 1, p. 87.

M. Polok-Rubiniec, K. Lukaszhowicz, L.A. Dobrzański, and M. Adamiak, Comparison of the PVD coatings deposited onto hot work tool steel and brass substrates, J. Achiev. Mater. Manuf. Eng., 24(2007), No. 2, p. 195.

R. Rebolé, A. Martínez, R. Rodriguez, G.G. Fuentes, E. Spain, N. Watson, J.C. Avelar-Batista, J. Housden, F. Montalá, L.J. Carreras, and T.J. Tate, Microstructural and tribological investigations of CrN coated, wet-stripped and recoated functional substrates used for cutting and forming tools, Thin Solid Films, 469–470(2004), p. 466.

M. Polok-Rubiniec, L.A. Dobrzański, and M. Adamiak, Comparison of the PVD coatings, Arch. Mater. Sci. Eng., 38(2009), No. 2, p. 118.

L.A. Dobrzański and L.W. Żukowska, Properties of the multicomponent and gradient PVD coatings, Arch. Mater. Sci. Eng., 28(2007), No. 10, p. 621.

H.C. Barshilia, B. Deepthi, N. Selvakumar, A. Jain, and K.S. Rajam, Nanolayered multilayer coatings of CrN/CrAlN prepared by reactive DC magnetron sputtering, Appl. Surf. Sci., 253(2007), p. 5076.

J. Soldán, J. Neidhardt, B. Sartory, R. Kaindl, R. Čerstvý, P.H. Mayrhofer, R. Tessadri, P. Polcik, M. Lechthaler, and C. Mitterer, Structure-property relations of arc-evaporated Al-Cr-Si-N coatings, Surf. Coat. Technol., 202(2008), p. 3555.

A.C. Fischer-Cripps, Critical review of analysis and interpretation of nanoindentation test data, Surf. Coat. Technol., 200(2006), p. 4153.

J. Musil, F. Kunc, H. Zeman, and H. Poláková, Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings, Surf. Coat. Technol., 154(2002), p. 304.

A. Sivitski, A. Gregor, M. Saarna, P. Kulu, and F. Sergejev, Application of the indentation method for cracking resistance evaluation of hard coatings on tool steels, Est. J. Eng., 15(2009), No. 4, p. 309.

S.E. Oraby and A.M. Alaskari, Atomic force microscopy (AFM) topographical surface characterization of multilayer-coated and uncoated carbide inserts, World Acad. Sci. Eng. Technol., 4(2010), p. 396.

M.A. Alaskari, S.E. Oraby, and A.I. Almazrouee, SEM and AFM investigations of surface defects and tool wear of multilayers coated carbide inserts, World Acad. Sci. Eng. Technol., 5(2011), p. 530.

H.C. Barshilia, B. Deepthi, K.S. Rajam, K.P. Bhatti, and S. Chaudhary, Growth and characterization of TiAlN/CrAlN superlattices prepared by reactive direct current magnetron sputtering, J. Vac. Sci. Technol. A, 27(2009), p. 29.

P.V. Zinin, V.L. Solozhenko, A.J. Malkin, and L.C. Ming, Atomic force microscopy studies of cubic BC2N, a new superhard phase, J. Mater. Sci., 40(2005), p. 3009.

B. Warcholinski and A. Gilewicz, Tribological properties of CrNx coatings, J. Achiev. Mater. Manuf. Eng., 37(2009), No. 2, p. 498.

M. Hagarová, I. Štěpánek, and D. Jakubéczyová, Evaluation of thin PVD coatings by adhesive-cohesive test, Acta Metall. Slovaca, 16(2010), No. 3, p. 157.

W. Pawlak and B. Wendler, Multilayer, hybrid PVD coatings on Ti6Al4V titanium alloy, J. Achiev. Mater. Manuf. Eng., 37(2009), No.2, p. 660.

X.L. Pang, K.W. Gao, F. Luo, Y. Emirov, A.A. Levin, and A.A. Volinsky, Investigation of microstructure and mechanical properties of multi-layer Cr/Cr2O3 coatings, Thin Solid Films, 517(2009), p. 1922.

LA. Dobrzański, S. Skrzypek, D. Pakula, J. Mikula, and A. Křiž, Influence of the PVD and CVD technologies on the residual macro stresses and functional properties of the coated tool ceramics, J. Achiev. Mater. Manuf. Eng., 35(2009), No. 2, p. 162.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sampath Kumar, T., Balasivanandha Prabu, S., Manivasagam, G. et al. Comparison of TiAlN, AlCrN, and AlCrN/TiAlN coatings for cutting-tool applications. Int J Miner Metall Mater 21, 796–805 (2014). https://doi.org/10.1007/s12613-014-0973-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0973-y