Abstract

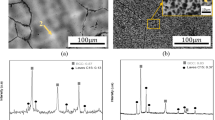

A novel diffusion couple method was used to investigate the interface diffusion of arsenic into a Nb-Ti microalloyed low carbon steel and its effects on phase transformation at the interface. It is discovered that the content of arsenic has great effect on grain growth and phase transformation at high temperature. When the arsenic content is no more than 1wt%, there is no obvious grain growth and no obvious ferrite transitional region formed at the diffusion interface. However, when the arsenic content is no less than 5wt%, the grain grows very rapidly. In addition, the arsenic-enriched ferrite transitional layer forms at the diffusion interface in the hot-rolling process, which results from a slower diffusion rate of arsenic atoms than that of carbon in ferrite.

Similar content being viewed by others

References

N. Balasubramanian, T. Kojima, and C. Srinivasakannan, Arsenic removal through electrocoagulation: kinetic and statistical modeling, Chem. Eng. J., 155(2009), No.1–2, p.76.

L. Debarberis, B. Acosta, A. Zeman, S. Pirfo, P. Moretto, A. Chernobaeva, and A. Nikolaev, Ductile-to-brittle transition temperature of thermally segregated WWER-1000 base metal, Int. J. Microstruct. Mater. Prop., 2(2007), No.3–4, p.326.

J. Navasaitis, A. Selskiene, and G. Žaldarys, The study of trace elements in bloomery iron, Mater. Sci., 16(2010), No.2, p.113.

Y. Ren, S. Zhang, S. Wang, and W.Y. Liu, Experimental study on 830 MPa grade pipeline steel containing chromium, Int. J. Miner., Metall. Mater., 16(2009), No.3, p.273.

B.W. Busch, T. Gustafsson, H. Viefhaus, and C. Uebing, Medium-energy ion scattering study of arsenic and sulfur segregation to the Fe-9% W(100) surface, Surf. Sci., 463(2000), No.2, p.145.

B.W. Busch, T. Gustafsson, and C. Uebing, Competition of arsenic and sulfur segregation on Fe-9% W(100) single crystal surfaces, Appl. Phys. Lett., 74(1999), p. 3564.

M.A. Islam, J.F. Knott, and P. Bowen, Critical level of intergranular fracture to affect the toughness of embrittled 2.25Cr-1Mo steels, J. Mater. Eng. Perform., 13(2004), No.5, p.600.

R.F. Tylecote, The composition of metal artifacts: a guide to provenance? Antiquity, 44(1970), No.173, p.19.

C.L. Yan, F.M. Wang, L.J. Wei, Q. Fu, and C.J. Wu, Improvement of Lanthanum on impact toughness of 34CrNi3Mo steel containing Sn, Sb residual elements, J. Univ. Sci. Technol. Beijing, 26(2004), No.3, p.277.

S. Dinda and W.R. Warke, The effect of grain boundary segregation on liquid metal induced embrittlement of steel, Mater. Sci. Eng., 24(1976), No.2, p.199.

Y.Z. Zhu, J. Rao, Z. Zhu, Z.D. Xiang, and Z.F. Wu, Surface inclusions and their evolution on strip rolled on CSP line and in following cold rolling process, Ironmaking Steelmaking, 36(2009), No.7, p.548.

M. M. Fetisova and É. I. Pleshakov, Mechanism underlying the reduction in the strength of an intergranular bond during the development of reversible temper embrittlement in steels, Sov. Mater. Sci., 11(1976), No.3, p.309.

Y.Z. Zhu, X.J. Cheng, Z.D. Xiang, and Z. Zhu, Scale accretion on homogenization furnace rollers in compact strip production mills and its densification mechanism, ISIJ Int., 48(2008), No.5, p.598.

Y.Z. Zhu, J.C. Li, D.M. Liang, and P. Liu, Distribution of arsenic on micro-interfaces in a kind of Cr, Nb and Ti microalloyed low carbon steel produced by a compact strip production process, Mater. Chem. Phys., 130(2011), No.1–2, p.524.

L.N. Kudryavtseva, K.N. Sokolov, and L.I. Yakushechkina, Effect of carbon on diffusion rate of arsenic, Met. Sci. Heat Treat., 17(1975), No.6, p.529.

D.G. Zhou, J. Fu, D.L. Liu, Y.L. Kang, Z.B. Wang, and Y.L. Wang, Forming mechanism and preventive measures of the surface crack in thin strip produced by CSP, J. Univ. Sci. Technol. Beijing, 24(2002), No.4, p.403.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the National Natural Science Foundation of China (No.50874083), the China Postdoctoral Science Foundation (No.201104493), and the China International Scientific and Technological Cooperation Projects (No.2010DFA52130).

Rights and permissions

About this article

Cite this article

Zhu, Yz., Xu, Jp. A method to study interface diffusion of arsenic into a Nb-Ti microalloyed low carbon steel. Int J Miner Metall Mater 19, 821–826 (2012). https://doi.org/10.1007/s12613-012-0634-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-012-0634-y