Abstract

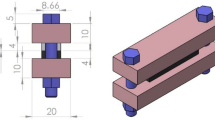

The superplastic deformation diffusion bonding of 00Cr25Ni7Mo3N duplex stainless steel was performed on a hot simulator. The microstructure of the bonding interface was characterized by scanning electron microscopy (SEM) and electron backscatter diffraction (EBSD). The mechanical properties of the specimen were investigated by a shear strength test. The results indicated that the shear strength was improved with the increase of superplastic deformation reduction. When the deformation reduction was up to 50%, the shear strength of the specimen achieved 417 Mpa, approaching to that of the base metal. In addtion, the superplastic diffusion bonding technique was not very sensitive to surface roughness levels. When the surface roughness of the bonding specimen surpassed 0.416 μm (level G2), the shear strength achieved at least 381 MPa.

Similar content being viewed by others

References

S.T. Kim, S.Y. Kim, I.S. Lee, Y.S. Park, M.C. Shin, and Y.S. Kim, Effects of shielding gases on the microstructure and localized corrosion of tube-to-tube sheet welds of super austenitic stainless steel for seawater cooled condenser, Corros. Sci., 53(2011), No.8, p.2611.

R.K.S. Raman and W.H. Siew, Role of nitrite addition in chloride stress corrosion cracking of a super duplex stainless steel, Corros. Sci., 52(2010), No.1, p.113.

G. Fargas, M. Anglada, and A. Mateo, Effect of the annealing temperature on the mechanical properties, formability and corrosion resistance of hot-rolled duplex stainless steel, J. Mater. Process. Technol., 209(2009), No.4, p.1770.

L.A. Dobrzański, Z. Brytan, M.A. Grande, and M. Rosso, Corrosion resistance of sintered duplex stainless steels in the salt fog spray test, J. Mater. Process. Technol., 192(2007), p.443.

L. Zhang, L.X. Wang, and X.P. Ren, Development of superplastic duplex austenitic-ferritic stainless steel 00Cr25Ni7Mo3N, Spec. Steel, 26(2005), No.6, p.44.

P.X. Zhang, X.P. Ren, J.X. Xie, B.Z. Zhang, W.D. Han, and J. Song, Superplasticity mechanism of duplex stainless steels, J. Univ. Sci. Technol. Beijing (in Chinese), 27(2005), No.1, p.68.

P.X. Zhang, X.P. Ren, J.X. Xie, and W. Wang, Effect of strain-induced transformation on grain refinement of SAF2205 during superplastic deformation, J. Univ. Sci. Technol. Beijing (in Chinese), 26(2004), No.1, p.56.

J.A. Jiménez, G. Frommeyer, M. Carsi, and O.A. Ruano, Superplastic properties of a δ/Γ stainless steel, Mater. Sci. Eng. A, 307(2001), p.134.

H. Miyamoto, T. Mimaki, and S. Hashimoto, Superplastic deformation of micro-specimens of duplex stainless steel, Mater. Sci. Eng. A, 319–321(2001), p.779.

H. Farnoush, A. Momeni, K. Dehghani, J.A. Mohandesi, and H. Keshmiri, Hot deformation characteristics of 2205 duplex stainless steel based on the behavior of constituent phases, Mater. Des., 31(2010), No.1, p.220.

Y.L. Fang, Y.M., Cheng, Y.X. Wang, and Z.Y. Liu, Hot deformation behavior of duplex stainless steels, J. Northeast. Univ. Nat. Sci., 30(2009), No.8, p.1124.

A. Weisbrodt-Reisch, M. Brummer, B. Hadler, B. Wolbank, and E.A. Werner, Influence of temperature, cold deformation and a constant mechanical load on the microstructural stability of a nitrogen alloyed duplex stainless steel, Mater. Sci. Eng. A, 416(2006), No.1–2, p.1.

S. Kundu, S. Sam, and S. Chatterjee, Interface microstructure and strength properties of Ti-6Al-4V and microduplex stainless steel diffusion bonded joints, Mater. Des., 32(2011), No.5, p.2997.

S. Kundu and S. Chatterjee, Diffusion bonding between commercially pure titanium and micro duplex stainless steel, Mater. Sci. Eng. A, 480(2008), No.1–2, p.316.

X.Y. Wang, L. Zhang, and M.X. Lu, Microstructure and properties of dissimilar weldment between duplex stainless steel and micro-alloyed steel, J. Univ. Sci. Technol. Beijing (in Chinese), 30(2008), No.2, p.131.

Y.S. Sato, T.W. Nelson, C.J. Sterling, and C.O. Petteersson, Microstructure and mechanical properties of friction stir welded SAF 2507 super duplex stainless steel, Mater. Sci. Eng. A, 397(2005), No.1–2, p.376.

P.X. Zhang, X.P. Ren, and J.X. Xie, Superplastic deformation of commercial 00Cr22Ni5Mo3N0.17 duplex stainless steel, J. Univ. Sci. Technol. Beijing, 10(2003), No.2, p.49.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Xh., Ren, Xp., Xu, H. et al. Effect of superplastic deformation on the bonding property of 00Cr25Ni7Mo3N duplex stainless steel. Int J Miner Metall Mater 19, 317–321 (2012). https://doi.org/10.1007/s12613-012-0557-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-012-0557-7