Abstract

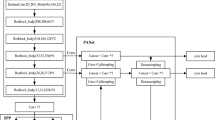

Surface defect detection is a complicated task to achieve both specific class and precise location of each defect. Specifically for industrial scenario, realizing efficient and accuracy-satisfactory surface defect automatic detection is still a big challenge. Therefore, a surface defect detection algorithm based on feature-enhanced YOLO (FE-YOLO) for practical industrial applications is proposed in this paper. For the purpose of efficient detection, we lighten YOLO model by combining deep separable convolution and dense join. And an improved feature pyramid network is proposed to enhance the spatial location correlation for multi-scale detection layer for the sake of high accuracy. Then, a new loss function of prediction box regression is established to boost the detection accuracy under the high Intersection over Union (IoU) threshold and accelerate model convergence. To select anchor boxes of different scale feature detection layers, we propose a statistical-based k-means++ algorithm, which can improve the quality of initial anchors and accelerate the convergence of the proposed model. Two industrial surface defect datasets, NEU-DET dataset and DeepPCB dataset, are used to verify the effectiveness of the proposed FE-YOLO algorithm. Experimental results demonstrate that FE-YOLO algorithm is lightened nearly 80% compared with YOLOV4. The detection speed is better than the other state-of-the-art surface defect detection algorithms. The defects detection accuracy respectively reaches 83.9% and 98.9% for the NEU-DET dataset and DeepPCB dataset, which are better than the state-of-the-art defect detection methods. The end-to-end fast and accurate detection for industrial surface defects is realized.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Forsyth DA. Computer vision: a modern approach. Upper Saddle River, NJ, USA: Prentice-Hall; 2002. p. 482–539.

Xie S, Xie Y, Ying H, Jiang Z, Gui W. Neurofuzzy-based plant-wide hierarchical coordinating optimization and control: an application to zinc hydrometallurgy plant. IEEE Trans Industr Electron. 2020;67:2207–19.

Zhang Y, Jin Y, Chen J, Kan S, Cen Y, Cao Q. PGAN: part-based nondirect coupling embedded GAN for person re-identification. IEEE Multimedia. 2020;27:23–33.

Cheon S, Lee H, Kim CO, Lee SH. Convolutional neural network for wafer surface defect classification and the detection of unknown defect class. IEEE Trans Semicond Manuf. 2019;32:163–70.

Wang H, Zhang J, Tian Y, Chen H, Sun H, Liu K. A simple guidance template-based defect detection method for strip steel surfaces. IEEE Trans Industr Inf. 2019;15:2798–809.

Choi D-C, Jeon Y-J, Kim S, Moon S, Yun J. Detection of pinholes in steel slabs using Gabor filter combination and morphological features. ISIJ Int. 2017;57:1045–53.

Zhao T, Chen X, Yang L. IPCA-SVM based real-time wrinkling detection approaches for strip steel production process. Int J Wirel Mob Comput. 2019;16:160–5.

Gao X, Jian M, Hu M, Tanniru M, Li S. Faster multi-defect detection system in shield tunnel using combination of FCN and faster RCNN. Adv Struct Eng. 2019;22:2907–21.

Cha Y, Choi W, Suh G, Mahmoudkhani S, Büyüköztürk O. Autonomous structural visual inspection using region-based deep learning for detecting multiple damage types. Comput Aided Civ Inf Eng. 2018;33:731–47.

Zhouhua Z, Shixia M, Tianyi Z. Multi-target defect intelligent recognition of transmission line based on improved faster-RCNN,” 2021 IEEE 4th International Conference on Automation, Electronics and Electrical Engineering (AUTEEE), 2021;pp. 597-60.

Chen J, Liu Z, Wang H, Núñez A, Han Z. Automatic defect detection of fasteners on the catenary support device using deep convolutional neural network. IEEE Trans Instrum Meas. 2018;67:257–69.

Mei S, Wang Y, Wen G. Automatic fabric defect detection with a multi-scale convolutional denoising autoencoder network model. Sensors (Basel, Switzerland), 2018;vol. 18.

Tao X, Zhang D, Wen-zhi M, Liu X, Xu D. Automatic metallic surface defect detection and recognition with convolutional neural networks. Appl Sci. 2018;8:1575.

Fu G, et al. A deep-learning-based approach for fast and robust steel surface defects classification. Opt Lasers Eng. 2019;121:397–405.

He Y, Song K, Dong H, Yan Y. Semi-supervised defect classification of steel surface based on multi-training and generative adversarial network. Opt Lasers Eng. 2019;122:294–302.

He Y, Song K, Meng Q, Yan Y. An end-to-end steel surface defect detection approach via fusing multiple hierarchical features. IEEE Trans Instrum Meas. 2020;69:1493–504.

Li W, Ye X, Zhao Y, Wang W. Strip steel surface defect detection based on improved YOLOv3 algorithm. Acta Electron Sin. 2020;48:1284–92.

Bochkovskiy A, Wang CY, Liao H. YOLOv4: Optimal speed and accuracy of object detection. ArXiv, vol. abs/2004.10934, 2020.

Redmon J, Divvala S, Girshick RB, Farhadi A. You only look once: unified, real-time object detection. 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), 2016;pp. 779-788.

Redmon J, Farhadi A. YOLO9000: better, faster, stronger. 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), 2017;pp. 6517-6525.

Farhadi A, Redmon J. Yolov3: an incremental improvement. In: Computer Vision and Pattern Recognition. Berlin/Heidelberg, Germany: Springer; 2018. p. 1804–2767.

Howard AG, et al. Searching for MobileNetV3. 2019 IEEE/CVF International Conference on Computer Vision (ICCV), 2019;pp. 1314-1324.

Howard AG, et al. MobileNets: Efficient convolutional neural networks for mobile vision applications. ArXiv, vol. abs/1704.04861, 2017.

Sandler M, Howard AG, Zhu M, Zhmoginov A, Chen LC. MobileNetV2: inverted residuals and linear bottlenecks. 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition, 2018;pp. 4510-4520.

Tan M, Le Q. EfficientNet: rethinking model scaling for convolutional neural networks. In International Conference on Machine Learning, 2019: PMLR, pp. 6105-6114.

Ma N, Zhang X, Zheng HT, Sun J. ShuffleNet V2: practical guidelines for efficient CNN architecture design. In ECCV, 2018.

Zhang X, Zhou X, Lin M, Sun J. ShuffleNet: an extremely efficient convolutional neural network for mobile devices. 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition, 2018;pp. 6848-6856.

Lin TY, Dollár P, Girshick RB, He K, Hariharan B, Belongie SJ. Feature pyramid networks for object detection. 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), 2017;pp. 936-944.

Zheng Z, Wang P, Liu W, Li J, Ye R, Ren D. Distance-IoU loss: faster and better learning for bounding box regression. Proceedings of the AAAI Conference on Artificial Intelligence. 2020;34(07):12993–3000.

Song K, Yan Y. A noise robust method based on completed local binary patterns for hot-rolled steel strip surface defects. Appl Surf Sci. 2013;285:858–64.

Wang K, Liew JH, Zou Y, Zhou D, Feng J. PANet: few-shot image semantic segmentation with prototype alignment. 2019 IEEE/CVF International Conference on Computer Vision (ICCV), 2019;pp. 9196-9205.

Tan M, Pang R, Le QV. Efficientdet: scalable and efficient object detection. In Proceedings of the IEEE/CVF conference on Computer Vision and Pattern Recognition, 2020;pp. 10781-10790.

Ren S, He K, Girshick RB, Sun J. Faster R-CNN: towards real-time object detection with region proposal networks. IEEE Trans Pattern Anal Mach Intell. 2015;39:1137–49.

Huang X, et al. PP-YOLOv2: a practical object detector. ArXiv, vol. abs/2104.10419, 2021.

Ge Z, Liu S, Wang F, Li Z, Sun J. YOLOX: Exceeding YOLO series in 2021. ArXiv, vol. abs/2107.08430, 2021.

He F, Tang S, Mehrkanoon S, Huang X, Yang J. A real-time PCB defect detector based on supervised and semi-supervised learning. In ESANN, 2020.

Funding

This study was funded in part by the Key-Area Research and Development Program of Guangdong Province (Grant No. 2021B0101200005), the State Key Program of National Natural Science of China (Grant No. 62233018), the National Natural Science Foundation of China (Grant No. 62003370), and the Nature Science Foundation of Hunan province (Grant No. 2021JJ30873).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics Approval

This article does not contain any experiments with human or animal participants performed by any of the authors.

Informed Consent

Informed consent was obtained from all individual participants included in the study.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, Y., Hu, W., Xie, S. et al. Surface Defect Detection Algorithm Based on Feature-Enhanced YOLO. Cogn Comput 15, 565–579 (2023). https://doi.org/10.1007/s12559-022-10061-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12559-022-10061-z