Abstract

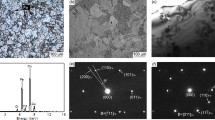

In order to obtain homogeneity and fine-scale microstructure of Cu–Fe alloy, a Cu-10 wt% Fe alloy slab was prepared by spray forming. The effects of cold rolling reduction on the alloy microstructure, mechanical properties, and electrical conductivity were studied. The results indicate that the Fe phase was fine and uniform with an average particle size of 4.16 μm, and the morphology of the particles was short rod or nearly spherical. The Cu matrix and Fe particles were gradually elongated, refined and finally formed into a distinct fiber structure along the rolling direction as the cold rolling reduction increased from 35 to 95%. The degree of deformation of the Cu matrix was more significant than that of the Fe phases at the same reduction, and more refined grains of the Cu matrix around the Fe phases. After cold rolling at 95% reduction, the Cu-10 wt% Fe exhibited an increase in tensile strength from 337 MPa in the initial state to 595 MPa, while the electrical conductivity decreased from 42.3% IACS to 20.2% IACS. The alloy deformation behavior and the strengthening mechanisms were illustrated. The combination of spray forming and cold rolling provides a novel approach to producing efficient, shortened process, environmentally friendly Cu–Fe alloy thin strips.

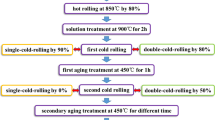

Graphical Abstract

A new process of preparing homogeneity and fine-scale microstructure Cu-10 wt% Fe alloy thin strip by spray forming and clod rolling is proposed. Fine and uniform Fe particles were obtained with an average size of 4.16 μm. Combined with the subsequent cold rolling, the effects of different reductions on the microstructure and mechanical properties after cold rolling were systematically studied. The specific abstract summary is as follows:

Similar content being viewed by others

References

S. Sarkar, C. Srivastava, K. Chattopadhyay, Development of a new class of high strength copper alloy using immiscibility route in Cu–Fe–Si system: evolution of hierarchical multi-scale microstructure. Mater. Sci. Eng. A 723, 38–47 (2018). https://doi.org/10.1016/j.msea.2018.03.026

H.R. Jo, J.T. Kim, S.H. Hong, Y.S. Kim, H.J. Park, W.J. Park, J.M. Park, K.B. Kim, Effect of silicon on microstructure and mechanical properties of Cu-Fe alloys. J. Alloys Compd. 707, 184–188 (2017). https://doi.org/10.1016/j.jallcom.2016.12.352

C. Zhang, C. Chen, L. Huang, T. Lu, P. Li, W. Wang, F. Yang, A.A. Volinsky, Z. Guo, Microstructure and properties of Cu–Fe alloys fabricated via powder metallurgy and rolling. Powder Metall. 64, 308–320 (2021). https://doi.org/10.1080/00325899.2021.1890403

T. Yamashita, N. Koga, T. Kawasaki, S. Morooka, S. Tomono, O. Umezawa, S. Harjo, Work hardening behavior of dual phase copper-iron alloy at low temperature. Mater. Sci. Eng. A 819, 141509 (2021). https://doi.org/10.1016/j.msea.2021.141509

N. Koga, W. Zhang, S. Tomono, O. Umezawal, Microstructure and low temperature tensile properties in Cu-50 mass% Fe alloy. Mater. Trans. 62, 57–61 (2020). https://doi.org/10.2320/matertrans.MT-M2020260

Z. Wu, Y. Chen, L. Meng, Z. Zhang, Effect of Fe content on the microstructure and mechanical and electrical properties of Cu–Fe in situ composites. J. Mater. Eng. Perform. 30, 5939–5946 (2021). https://doi.org/10.1007/s11665-021-05579-6

J.T. Zhang, W.X. Hao, J.B. Lin, Y.H. Wang, H.Q. Chen, Effects of carbon element on the formed microstructure in undercooled Cu–Fe–C alloys. J. Alloys Compd. 827, 154285 (2020). https://doi.org/10.1016/j.jallcom.2020.154285

G.C. Kang, S.H. Hong, H.J. Park, J.P. Lee, J.K. Lee, W.M. Wang, K.B. Kim, Influence of grain boundary modification on color transition behavior of Cu–Al–Zn–Sn alloys with low stacking fault energy. J. Alloys Compd. 960, 171033 (2023). https://doi.org/10.1016/j.jallcom.2023.171033

S.H. Hong, S.C. Mun, G.C. Kang, H.J. Park, Y.B. Jeong, G. Song, K.B. Kim, Recent development of coloring alloys. Prog. Mater. Sci. 123, 100811 (2022). https://doi.org/10.1016/j.pmatsci.2021.100811

Y.B. Jeong, S.H. Hong, J.T. Kim, H.J. Park, Y.S. Kim, H.D. Lee, J.K. Lee, S.C. Mun, Y.J. Hwang, K. Heo, K.B. Kim, Investigation on the relationship between transition energy and the color change of Cu–M alloys. Met. Mater. Int. 25, 539–545 (2019). https://doi.org/10.1007/s12540-018-0205-5

Y. Nakagawa, Liquid immiscibility in copper-iron and copper-cobalt systems in the supercooled state. Acta Mater. 6, 704–711 (1958). https://doi.org/10.1016/0001-6160(58)90061-0

D.W. Yuan, H. Zeng, X.P. Xiao, H. Wang, B.J. Han, B.X. Liu, B. Yang, Effect of Mg addition on Fe phase morphology distribution and aging kinetics of Cu-6.5Fe alloy. Mater. Sci. Eng. A 812, 141064 (2021). https://doi.org/10.1016/j.msea.2021.141064

S. Bysakh, K. Chattopadhyay, T. Maiwald, R. Galun, B.L. Mordike, Microstructure evolution in laser alloyed layer of Cu–Fe–Al–Si on Cu substrate. Mater. Sci. Eng. A 375–377, 661–665 (2004). https://doi.org/10.1016/j.msea.2003.10.263

D.W. Yuan, X.P. Xiao, X. Luo, H. Wang, B.J. Han, B.X. Liu, B. Yang, Effect of multistage thermomechanical treatment on Fe phase evolution and properties of Cu- 6.5Fe-0.3Mg alloy. Mater. Charact. 185, 111707 (2022). https://doi.org/10.1016/j.matchar.2021.111707

X. Luo, D.W. Yuan, H. Wang, H. Chen, X.P. Xiao, B.J. Han, H. Huang, B. Yang, Multi-stage thermomechanical treatment Cu-6.5Fe-xMg alloy: excellent physical and mechanical properties. J. Magn. Magn. Mater. 556, 169407 (2022). https://doi.org/10.1016/j.jmmm.2022.169407

Y.B. Jeong, H.R. Jo, J.T. Kim, S.H. Hong, K.B. Kim, A study on the micro-evolution of mechanical property and microstructures in (Cu-30Fe)-2X alloys with the addition of minor alloying elements. J. Alloys Compd. 786, 341–345 (2019). https://doi.org/10.1016/j.jallcom.2019.01.169

Y.J. Pang, G.H. Chao, T.Y. Luan, S. Gong, Y.R. Wang, Z.H. Jiang, X. Zhu, Y.B. Jiang, Z. Li, Microstructure and properties of high strength, high conductivity and magnetic Cu-10Fe-0.4Si alloy. Mater. Sci. Eng. A 826, 142012 (2021). https://doi.org/10.1016/j.msea.2021.142012

P. Zhang, X.B. Yuan, Y.D. Li, Y.H. Zhou, R.L. Lai, Y.P. Li, Q. Lei, A. Chiba, Influence of minor Ag addition on the microstructure and properties of powder metallurgy Cu-10wt% Fe alloy. J. Alloys Compd. 904, 163983 (2022). https://doi.org/10.1016/j.jallcom.2022.163983

D.W. Yuan, X.P. Xiao, J.S. Chen, B.J. Han, H. Huang, B. Yang, Influence of Ag addition on the microstructure and properties of Cu-6.5Fe-0.2Cr alloy prepared by upward continuous casting. J. Alloys Compd. 887, 161458 (2021). https://doi.org/10.1016/j.jallcom.2021.161458

L. Ren, S.R. Zhang, J.Q. Shi, Z. Shen, P.J. Shi, T.X. Zheng, B. Ding, Y.F. Guo, Q.L. Xiao, Q. Li, Y.B. Zhong, Grain refinement and mechanical properties enhancement of Cu-10 wt% Fe alloys via Zr addition. Mater. Sci. Eng. A 846, 143309 (2022). https://doi.org/10.1016/j.msea.2022.143309

H.J. Moon, T.M. Yeo, S.H. Lee, J.W. Cho, Effect of Zr addition on metastable liquid-liquid phase separation of Cu–Fe alloys. Scr. Mater. 205, 114218 (2021). https://doi.org/10.1016/j.scriptamat.2021.114218

M. Wang, R. Zhang, Z. Xiao, S. Gong, Y.B. Jiang, Z. Li, Microstructure and properties of Cu-10 wt% Fe alloy produced by double melt mixed casting and multistage thermomechanical treatment. J. Alloys Compd. 820, 153323 (2020). https://doi.org/10.1016/j.jallcom.2019.153323

M. Wang, Y.B. Jiang, Z. Li, Z. Xiao, S. Gong, W.T. Qiu, Q. Lei, Microstructure evolution and deformation behaviour of Cu-10 wt% Fe alloy during cold rolling. Mater. Sci. Eng. A 801, 140379 (2021). https://doi.org/10.1016/j.msea.2020.140379

A. Chatterjee, E. Sprague, J. Mazumder, A. Misra, Hierarchical microstructures and deformation behavior of laser direct-metal-deposited Cu–Fe alloys. Mater. Sci. Eng. A 802, 140659 (2021). https://doi.org/10.1016/j.msea.2020.140659

Y.D. Li, X.B. Yuan, B.B. Yang, X.J. Ye, P. Zhang, H.Y. Lang, Q. Lei, J.T. Liu, Y.P. Li, Hierarchical microstructure and strengthening mechanism of Cu-36.8Fe alloy manufactured by selective laser melting. J. Alloys Compd. 895, 162701 (2022). https://doi.org/10.1016/j.jallcom.2021.162701

X.Q. Dai, M. Xie, S.F. Zhou, C.X. Wang, M.H. Gu, J.X. Yang, Z.Y. Li, Formation mechanism and improved properties of Cu95Fe5 homogeneous immiscible composite coating by the combination of mechanical alloying and laser cladding. J. Alloys Compd. 740, 194–202 (2018). https://doi.org/10.1016/j.jallcom.2018.01.007

B.X. Song, T.B. Yu, X.Y. Jiang, W.C. Xi, X.L. Lin, Effect of W content on the microstructure and properties of Cu–Fe alloy. J. Mater. Res. Technol. 9, 6464–6474 (2020). https://doi.org/10.1016/j.jmrt.2020.04.031

J.M. Guo, Q.Q. Shao, O. Renk, L. Li, Y.B. He, Z.L. Zhang, R. Pippan, Combined Fe and O effects on microstructural evolution and strengthening in Cu–Fe nanocrystalline alloys. Mater. Sci. Eng. A 772, 138800 (2020). https://doi.org/10.1016/j.msea.2019.138800

N. Koga, S. Tomono, O. Umezawa, Low-temperature tensile properties of Cu-Fe laminated sheets with various number of layers. Mater. Sci. Eng. A 811, 141066 (2021). https://doi.org/10.1016/j.msea.2021.141066

J. Eckert, J.C. Holzer, C.E. Krill, W.L. Johnson, Mechanically driven alloying and grain size changes in nanocrystalline Fe–Cu powders. J. Appl. Phys. 73, 2794–2802 (1993). https://doi.org/10.1063/1.353055

C.Z. Zhang, C.G. Chen, P. Li, M.J. Yan, Q. Qin, F. Yang, W.W. Wang, Z.M. Guo, A.A. Volinsky, Microstructure and properties evolution of rolled powder metallurgy Cu-30Fe alloy. J. Alloys Compd. 909, 164761 (2022). https://doi.org/10.1016/j.jallcom.2022.164761

C.Z. Zhang, C.G. Chen, X.H. Liu, M.J. Yan, M. Qin, X.C. Li, Y. Li, H.F. Zhang, F. Yang, W.W. Wang, Z.M. Guo, High strength and high electrical conductivity in Cu–Fe alloys with nano and micro Fe particles. Mater. Sci. Eng. A 855, 143948 (2022). https://doi.org/10.1016/j.msea.2022.143948

F.L. Wang, K. Wakoh, Y.P. Li, S. Ito, K. Yamanaka, Y. Koizumi, A. Chiba, Study of microstructure evolution and properties of Cu–Fe microcomposites produced by a pre-alloyed powder method. Mater. Des. 126, 64–72 (2017). https://doi.org/10.1016/j.matdes.2017.04.017

L.L. Liu, Q.L. Pan, X.D. Wang, S.W. Xiong, The effects of aging treatments on mechanical property and corrosion behavior of spray formed 7055 aluminium alloy. J. Alloys Compd. 735, 261–276 (2018). https://doi.org/10.1016/j.jallcom.2017.11.070

P.S. Grant, Spray forming. Prog. Mater. Sci. 39, 497–545 (1995). https://doi.org/10.1016/0079-6425(95)00004-6

L.J. Wei, B.S. Han, F. Ye, A. Ditta, L. Li, Y.J. Xu, S.J. Wu, Influencing mechanisms of heat treatments on microstructure and comprehensive properties of Al–Zn–Mg–Cu alloy formed by spray forming. J. Mater. Res. Technol. 9, 6850–6858 (2020). https://doi.org/10.1016/j.jmrt.2020.03.121

K. Guo, K. Meng, D. Miao, Q. Wang, C. Zhang, T. Wang, Effect of annealing on microstructure and tensile properties of skew hot rolled Ti-6Al-3Nb-2Zr-1Mo alloy tube. Mater. Sci. Eng. A 766, 138346 (2019). https://doi.org/10.1016/j.msea.2019.138346

A. Ünal, Influence of gas flow on performance of confined atomization nozzles. Metall. Mater. Trans. B 20, 833–843 (1989). https://doi.org/10.1007/BF02670188

S.F. Abbas, S.J. Seo, K.T. Park, B.S. Kim, T.S. Kim, Effect of grain size on the electrical conductivity of copper-iron alloys. J. Alloys Compd. 720, 8–16 (2017). https://doi.org/10.1016/j.jallcom.2017.05.244

G.K. Williamson, W.H. Hall, X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1, 22–31 (1953). https://doi.org/10.1016/0001-6160(53)90006-6

T. Ungar, S. Ott, P.G. Sanders, A. Borbely, J.R. Weertman, Dislocations, grain size and planar faults in nanostructured copper determined by high resolution X-ray diffraction and a new procedure of peak profile analysis. Acta Mater. 46, 3693–3699 (1998). https://doi.org/10.1016/S1359-6454(98)00001-9

F. Hajyakbary, J. Sietsma, A.J. Bottger, M.J. Santofimia, An improved X-ray diffraction analysis method to characterize dislocation density in lath martensitic structures. Mater. Sci. Eng. A 639, 208–218 (2015). https://doi.org/10.1016/j.msea.2015.05.003

W.A. Spitzig, A.R. Pelton, F.C. Laabs, Characterization of the strength and microstructure of heavily cold worked Cu–Nb composites. Acta Metall. 35, 2427–2442 (1987). https://doi.org/10.1016/0001-6160(87)90140-4

W.A. Spitzig, S.B. Biner, Comparison of strengthening in wire-drawn or rolled Cu-20% Nb with a dislocation accumulation model. J. Mater. Sci. 28, 4623–4629 (1993). https://doi.org/10.1007/BF00414250

P.H.F. Oliveira, D.C.C. Magalhães, M.T. Izumi, O.M. Cintho, A.M. Kliauga, V.L. Sordi, Evolution of dislocation and stacking-fault densities for a Cu-0.7Cr-0.07Zr alloy during cryogenic tensile test: an in-situ synchrotron X-ray diffraction analysis. Mater. Sci. Eng. A 813, 141154 (2021). https://doi.org/10.1016/j.msea.2021.141154

Y.P. Li, Z. Xiao, Z. Li, Z.Y. Zhou, Z.Q. Yang, Q. Lei, Microstructure and properties of a novel Cu–Mg–Ca alloy with high strength and high electrical conductivity. J. Alloys Compd. 723, 1162–1170 (2017). https://doi.org/10.1016/j.jallcom.2017.06.155

K. Ma, H. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, J.M. Schoenung, Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 62, 141–155 (2014). https://doi.org/10.1016/j.actamat.2013.09.042

M. Furukawa, Z. Horita, M. Nemoto, R.Z. Valiev, T.G. Langdon, Structural evolution and validity of Hall-Petch relationship in an Al-3% Mg alloy with submicron grain size. Mater. Sci. Forum 204–206, 431–436 (1996). https://doi.org/10.4028/www.scientific.net/MSF.204-206.431

A. Mohammadi, N.A. Enikeev, M.Y. Murashkin, M. Arita, K. Edalati, Examination of inverse Hall-Petch relation in nanostructured aluminum alloys by ultra-severe plastic deformation. J. Mater. Sci. Technol. 91, 78–89 (2021). https://doi.org/10.1016/j.jmst.2021.01.096

Q. Lei, Z. Xiao, W.P. Hu, B. Derby, Z. Li, Phase transformation behaviors and properties of a high strength Cu–Ni–Si alloy. Mater. Sci. Eng. A 697, 37–47 (2017). https://doi.org/10.1016/j.msea.2017.05.001

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, Z.P. Lu, A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 102, 187–196 (2016). https://doi.org/10.1016/j.actamat.2015.08.076

R.G. Li, S.R. Zhang, C.L. Zou, H.J. Kang, T.M. Wang, The roles of Hf element in optimizing strength, ductility and electrical conductivity of copper alloys. Mater. Sci. Eng. A 758, 130–138 (2019). https://doi.org/10.1016/j.msea.2019.04.110

Z. Shen, Z.Z. Lin, P.J. Shi, J.L. Zhu, T.X. Zheng, B. Ding, Y.F. Guo, Y.B. Zhong, Enhanced electrical, mechanical and tribological properties of Cu–Cr–Zr alloys by continuous extrusion forming and subsequent ageing treatment. J. Mater. Sci. Technol. 110, 187–197 (2021). https://doi.org/10.1016/j.jmst.2021.10.012

Y. Wu, Y. Li, J.Y. Lu, S. Tan, F. Jiang, J. Sun, Correlations between microstructures and properties of Cu–Ni–Si–Cr alloy. Mater. Sci. Eng. A 731, 403–412 (2018). https://doi.org/10.1016/j.msea.2018.06.075

D. Li, M.B. Robinson, T.J. Rathz, G. Williams, Liquidus temperatures and solidification behavior in the copper-niobium system. Acta Mater. 46(11), 3849–3855 (1998). https://doi.org/10.1016/S1359-6454(98)00063-9

H.W. Fu, Y.W. Yin, Y. Zhang, M.Y. Zhang, X.B. Yun, Enhancing the comprehensive properties of as-cast Cu–Ni–Si alloys by continuous extrusion combined with subsequent thermomechanical treatment. Mater. Des. 222, 111033 (2022). https://doi.org/10.1016/j.matdes.2022.111033

H.Y. Gao, J. Wang, S. Da, B.D. Sun, Effect of Ag on the microstructure and properties of Cu–Fe in situ composites. Scr. Mater. 53, 1105–1109 (2005). https://doi.org/10.1016/j.scriptamat.2005.07.028

J.D. Verhoeven, H.L. Downing, L.S. Chumbley, E.D. Gibson, The resistivity and microstructure of heavily drawn Cu–Nb alloys. J. Appl. Phys. 65, 1293 (1989). https://doi.org/10.1063/1.343024

C. Bisellp, D.G. Morris, Microstructure and strength of Cu–Fe in situ composites obtained from prealloyed Cu–Fe powders. Acta Metall. Mater. 42, 163–176 (1994). https://doi.org/10.1016/0956-7151(94)90059-0

L. Qu, E.G. Wang, K. Han, X.W. Zuo, L. Zhang, P. Jia, J.C. He, Studies of electrical resistivity of an annealed Cu–Fe composite. J. Appl. Phys. 113, 73708 (2013). https://doi.org/10.1063/1.4803716

Y.Z. Tian, Y. Yang, S.Y. Peng, X.Y. Pang, S. Li, M. Jiang, H.X. Li, J.W. Wang, G.W. Qin, Managing mechanical and electrical properties of nanostructured Cu–Fe composite by aging treatment. Mater. Charact. 196, 112600 (2023). https://doi.org/10.1016/j.matchar.2022.112600

P. Zhang, Q. Lei, X.B. Yuan, X.F. Sheng, D. Jiang, Y.P. Lia, Z. Li, Microstructure and mechanical properties of a Cu–Fe–Nb alloy with a high product of the strength times the elongation. Mater. Today Commun. 25, 101353 (2020). https://doi.org/10.1016/j.mtcomm.2020.101353

N.D. Stepanov, A.V. Kuznetsov, G.A. Salishchev, N.E. Khlebova, V.I. Pantsyrny, Evolution of microstructure and mechanical properties in Cu-14%Fe alloy during severe cold rolling. Mater. Sci. Eng. A 564, 264–272 (2013). https://doi.org/10.1016/j.msea.2012.11.121

K. Yang, M.X. Guo, H. Wang, X.G. Dong, L. Yi, H.F. Lou, Coordinated deformation behavior of Cu-10wt%FeC alloys through controlling structure morphology and distribution of Fe-C phases. J. Mater. Res. Technol. 22, 1610–1624 (2023). https://doi.org/10.1016/j.jmrt.2022.12.020

Y.J. Ding, Z. Xiao, M. Fang, S. Gong, J. Dai, Microstructure and mechanical properties of multi-scale α-Fe reinforced Cu–Fe composite produced by vacuum suction casting. Mater. Sci. Eng. A 864, 144603 (2023). https://doi.org/10.1016/j.msea.2023.144603

M. Wang, Q.R. Yang, Y.B. Jiang, Z. Li, Z. Xiao, S. Gong, Y.R. Wang, C.L. Guo, H.G. Wei, Effects of Fe content on microstructure and properties of Cu–Fe alloy. Trans. Nonferrous Met. Soc. China 31, 3039–3049 (2021). https://doi.org/10.1016/S1003-6326(21)65713-8

Acknowledgements

This research is financially supported by the Open Fund Project of State Key Laboratory for Comprehensive Utilization of Vanadium and Titanium Resources (No. 2021P4FZG12A), the National Natural Science Foundation of China (No. 51274063) and the National Key R&D Program of China (No. 2017YFB0304100).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, S., Niu, Wy., Wang, Gq. et al. Microstructure Evolution and Property of Spray-Formed Cu-10 wt% Fe Alloy During Cold Rolling. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01626-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01626-8