Abstract

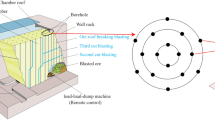

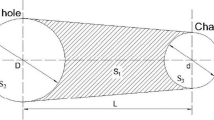

Due to the high in situ stress of the deep rock mass and the restraining effect of the surrounding rock, the deep hole blasting of vertical shaft faces the problems of low borehole utilization rate and poor blasting effect. In this regard, this paper proposes a deep hole multi-stage cut blasting technology of vertical shaft. Preliminary engineering practice shows that such cut blasting technology can make better use of explosive energy, reduce the restraining effect of surrounding rock, and increase the borehole utilization rate. Furthermore, based on the continuum-based discrete element method (CDEM), the fractal damage, fragmentation, and blasting cavity characteristics of deep hole multi-stage cut blasting of vertical shaft are studied and analyzed. The results show that in the multi-stage cut blasting of vertical shaft, if the length proportion of the first stage is too small or too large, it will lead to poor cavity formation along the cut direction. Characteristic parameters such as fractal damage of blasting cavity, fracture degree of element, and fracture degree of interface show a trend of first increasing and then decreasing as the length proportion of the first stage increases, and the length proportion of the first stage has an optimal value. Under the conditions of rock parameters, explosive performance and linear charge density set by the numerical simulation in this paper, when the length proportion of the first stage accounts for 0.42, the multi-stage cut blasting of vertical shaft can make better use of explosive energy and achieve the best blasting effect.

Similar content being viewed by others

References

Cheng B, Wang HB, Zong Q, Xu Y, Wang MX, Zheng QQ, Li CJ (2020) A study on cut blasting with large diameter charges in hard rock roadways. Adv Civ Eng Article ID:8873412

Diering DH (1997) Ultra-deep level mining: future requirements. J S Afr I Min Metall 97(6):249–255

Ding CX, Yang RS, Feng C (2021a) Stress wave superposition effect and crack initiation mechanism between two adjacent boreholes. Int J Rock Mech Min Sci 138:104622

Ding CX, Yang RS, Yang LY (2021b) Experimental results of blast-induced cracking fractal characteristics and propagation behavior in deep rock mass. Int J Rock Mech Min Sci 142:104772

Ding CX, Yang RS, Lei Z, Wang M, Zhao Y, Lin H (2021c) Fractal damage and crack propagation in decoupled charge blasting. Soil Dyn Earthq Eng 141:106503

Feng C, Li SH, Liu XY (2011) Semi-spring contact model and its application to failure simulation of slope. Chinese J Theor Appl Mech 43(1):184–192

Feng C, Li SH, Liu XY, Zhang YN (2014) A semi-spring and semi-edge combined contact model in CDEM and its application to analysis of Jiweishan landslide. J Rock Mech Geotech Eng 6(1):26–35

Feng C, Li SH, Zheng BX, Cui XR, Jia JJ (2019) Numerical simulation on complete process of three-dimensional bench blasting in an open-pit mine based on CDEM. Explo Shock Wave 39(2):024201

Ju Y, Wang YL, Su CS, Zhang DS, Ren ZY (2019) Numerical analysis of the dynamic evolution of mining-induced stresses and fractures in multilayered rock strata using continuum-based discrete element methods. Int J Rock Mech Min Sci 113:191–210

Langefors U, Kihstrom B, 1963. The modern technique of rock blasting. JohnWiley&Sons Cc.

Li SH, Wang JG, Liu BS, Dong DP (2007) Analysis of critical excavation depth for a jointed rock slope using a face-to-face discrete element method. Rock Mech Rock Eng 40(4):331–348

Liu F, Chang KL, Li M (2019) Numerical simulation on the influence of boreholes arrangement and delay time on coal crushing effects. J Min Sci Technol 4(4):318–326

Shan RL, Huang BL, Gao WJ, Zhu Y, Hao XY (2011) Case studies of new technology application of quasi-parallel cut blasting in rock roadway drivage. Chin J Rock Mech Eng 30(2):224–232

Shan RL, Huang BL, Wei ZT, Kong XS (2012) Model test of quasi-parallel cut blasting in rock drivage. Chin J Rock Mech Eng 31(2):256–264

Vogel M, Andrast HP (2000) Alp transit-safety in construction as a challenge, health and safety aspects in very deep tunnel construction. Tunn Undergr Sp Tech 15(4):481–484

Wang JF (1984) Discussion on the operation mode of shaft construction. Mine Constr Tech 4:46–51

Wang YB, Yu BB, Kong J, Wang ZY, Wu HW (2020) Methods and devices for evaluation of blasting damage to indoor small quantity rock. J Min Sci Technol 5(6):624–631

Yang RS, Yang GL, Gao XT, 2017. Theory and practice of directional fracture controlled blasting. Science Press.

Zhang ZX, 2016. Rock fracture and blasting: theory and applications. Elsevier.

Funding

This research was supported by (1) Fundamental Research Funds for the Central Universities (FRF-TP-20-044A1), (2) China Postdoctoral Science Foundation (2020 M680354), (3) National Natural Science Foundation of China (51934001, 51974316).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Responsible Editor: Murat Karakus

Rights and permissions

About this article

Cite this article

Ding, C., Yang, R., Zheng, C. et al. Numerical analysis of deep hole multi-stage cut blasting of vertical shaft using a continuum-based discrete element method. Arab J Geosci 14, 1086 (2021). https://doi.org/10.1007/s12517-021-07425-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-07425-4