Abstract

Three-dimensional (3D) nanoarchitectures have offered unprecedented material performances in diverse applications like energy storages, catalysts, electronic, mechanical, and photonic devices. These outstanding performances are attributed to unusual material properties at the nanoscale, enormous surface areas, a geometrical uniqueness, and comparable feature sizes with optical wavelengths. For the practical use of the unusual nanoscale properties, there have been developments for macroscale fabrications of the 3D nanoarchitectures with process areas over centimeter scales. Among the many fabrication methods for 3D structures at the nanoscale, proximity-field nanopatterning (PnP) is one of the promising techniques that generates 3D optical holographic images and transforms them into material structures through a lithographic process. Using conformal and transparent phase masks as a key factor, the PnP process has advantages in terms of stability, uniformity, and reproducibility for 3D nanostructures with periods from 300 nm to several micrometers. Other merits of realizing precise 3D features with sub-100 nm and rapid processes are attributed to the interference of coherent light diffracted by phase masks. In this review, to report the overall progress of PnP from 2003, we present a comprehensive understanding of PnP, including its brief history, the fundamental principles, symmetry control of 3D nanoarchitectures, material issues for the phase masks, and the process area expansion to the wafer-scale for the target applications. Finally, technical challenges and prospects are discussed for further development and practical applications of the PnP technique.

Similar content being viewed by others

References

Hariharan, P. Basics of Interferometry; Elsevier: Amsterdam, 2010.

Vargas, J.; Quiroga, J. A.; Belenguer, T. Phase-shifting interferometry based on principal component analysis. Opt. Lett. 2011, 36, 1326–1328.

Yashiro, W.; Takeda, Y.; Momose, A. Efficiency of capturing a phase image using cone-beam X-ray Talbot interferometry. J. Opt. Soc. Am. A 2008, 25, 2025–2039.

Wyrowski, F. Diffractive optical elements: Iterative calculation of quantized, blazed phase structures. J. Opt. Soc. Am. A 1990, 7, 961–969.

Antoniades, M. A.; Eleftheriades, G. V. A broadband series power divider using zero-degree metamaterial phase-shifting lines. IEEE Microw. Wirel. Compon. Lett. 2005, 15, 808–810.

Dolling, G.; Enkrich, C.; Wegener, M.; Soukoulis, C. M.; Linden, S. Simultaneous negative phase and group velocity of light in a metamaterial. Science 2006, 312, 892–894.

Larouche, S.; Tsai, Y. J.; Tyler, T.; Jokerst, N. M.; Smith, D. R. Infrared metamaterial phase holograms. Nat. Mater. 2012, 11, 450–454.

Zhu, R.; Liu, X. N.; Hu, G. K.; Sun, C. T.; Huang, G. L. Negative refraction of elastic waves at the deep-subwavelength scale in a single-phase metamaterial. Nat. Commun. 2014, 5, 5510.

Campbell, M.; Sharp, D. N.; Harrison, M. T.; Denning, R. G.; Turberfield, A. J. Fabrication of photonic crystals for the visible spectrum by holographic lithography. Nature 2000, 404, 53–56.

Liebmann, L. W.; Bukofsky, S. J.; Graur, I. Generating mask patterns for alternating phase-shift mask lithography. U.S. Patent 7475380, January 6, 2009.

Perlitz, S.; Buttgereit, U.; Scherübl, T.; Seidel, D.; Lee, K. M.; Tavassoli, M. Novel solution for in-die phase control under scanner equivalent optical settings for 45-nm node and below. In Proceedings of SPIE 6607, Photomask and Next-Generation Lithography Mask Technology XIV, Yokohama, Japan, 2007, p 66070Z.

Tritchkov, A.; Jeong, S.; Kenyon, C. Lithography enabling for the 65 nm node gate layer patterning with alternating PSM. In Proceedings of SPIE 6607, Optical Microlithography XVIII, San Jose, California, USA, 2005, pp 215–225.

Levenson, M. D.; Viswanathan, N. S.; Simpson, R. A. Improving resolution in photolithography with a phase-shifting mask. IEEE Trans. Electron Devices 1982, 29, 1828–1836.

Wong, A. K. K. Resolution Enhancement Techniques in Optical Lithography; SPIE Press: Bellingham, 2001.

Weichelt, T.; Vogler, U.; Stuerzebecher, L.; Voelkel, R.; Zeitner, U. D. Resolution enhancement for advanced mask aligner lithography using phase-shifting photomasks. Opt. Express 2014, 22, 16310–16321.

Odom, T. W.; Love, J. C.; Wolfe, D. B.; Paul, K. E.; Whitesides, G. M. Improved pattern transfer in soft lithography using composite stamps. Langmuir 2002, 18, 5314–5320.

Xia, Y. N.; Whitesides, G. M. Soft lithography. Annu. Rev. Mater. Sci. 1998, 28, 153–184.

Qin, D.; Xia, Y. N.; Whitesides, G. M. Soft lithography for micro- and nanoscale patterning. Nat. Protoc. 2010, 5, 491–502.

Jeon, S.; Menard, E.; Park, J. U.; Maria, J.; Meitl, M.; Zaumseil, J.; Rogers, J. A. Three-dimensional nanofabrication with rubber stamps and conformable photomasks. Adv. Mater. 2004, 16, 1369–1373.

Rogers, J. A.; Paul, K. E.; Jackman, R. J.; Whitesides, G. M. Generating ∼ 90 nanometer features using near-field contact-mode photolithography with an elastomeric phase mask. J. Vac. Sci. Technol. B 1998, 16, 59–68.

Rogers, J. A.; Paul, K. E.; Jackman, R. J.; Whitesides, G. M. Using an elastomeric phase mask for sub-100 nm photolithography in the optical near field. Appl. Phys. Lett. 1997, 70, 2658–2660.

Aizenberg, J.; Rogers, J. A.; Paul, K. E.; Whitesides, G. M. Imaging profiles of light intensity in the near field: Applications to phase-shift photolithography. Appl. Opt. 1998, 37, 2145–2152.

Maria, J.; Jeon, S.; Rogers, J. A. Nanopatterning with conformable phase masks. J. Photochem. Photobiol. A 2004, 166, 149–154.

Aizenberg, J.; Rogers, J. A.; Paul, K. E.; Whitesides, G. M. Imaging the irradiance distribution in the optical near field. Appl. Phys. Lett. 1997, 71, 3773–3775.

Wang, F.; Horn, M. W.; Lakhtakia, A. Rigorous electromagnetic modeling of near-field phase-shifting contact lithography. Microelectron. Eng. 2004, 71, 34–53.

Li, Z. Y.; Yin, Y. D.; Xia, Y. N. Optimization of elastomeric phase masks for near-field photolithography. Appl. Phys. Lett. 2001, 78, 2431–2433.

Jeon, S.; Park, J. U.; Cirelli, R.; Yang, S.; Heitzman, C. E.; Braun, P. V.; Kenis, P. J. A.; Rogers, J. A. Fabricating complex three-dimensional nanostructures with high-resolution conformable phase masks. Proc. Natl. Acad. Sci. USA 2004, 101, 12428–12433.

Shir, D. J.; Jeon, S.; Liao, H. W.; Highland, M.; Cahill, D. G.; Su, M. F.; El-Kady, I. F.; Christodoulou, C. G.; Bogart, G. R.; Hamza, A. V. et al. Three-dimensional nanofabrication with elastomeric phase masks. J. Phys. Chem. B 2007, 111, 12945–12958.

Park, J. Y.; Jeon, S. W. Large-Area, Three-dimensional nanopatterning with conformal phase masks. Polym. Sci. Technol. 2013, 24, 517–527.

Ahn, C.; Park, J.; Cho, D.; Hyun, G.; Ham, Y.; Kim, K.; Nam, S. H.; Bae, G.; Lee, K.; Shim, Y. S. et al. High-performance functional nanocomposites using 3D ordered and continuous nanostructures generated from proximity-field nanopatterning. Funct. Compos. Struct. 2019, 1, 032002.

Hua, F.; Sun, Y. G.; Gaur, A.; Meitl, M. A.; Bilhaut, L.; Rotkina, L.; Wang, J. F.; Geil, P.; Shim, M.; Rogers, J. A. et al. Polymer imprint lithography with molecular-scale resolution. Nano Lett. 2004, 4, 2467–2471.

Zhang, J.; Tan, K. L.; Gong, H. Q. Characterization of the polymerization of SU-8 photoresist and its applications in microelectro-mechanical systems (MEMS). Polym. Test. 2001, 20, 693–701.

Lin, C. H.; Lee, G. B.; Chang, B. W.; Chang, G. L. A new fabrication process for ultra-thick microfluidic microstructures utilizing SU-8 photoresist. J. Micromech. Microeng. 2002, 12, 590.

Conradie, E. H.; Moore, D. F. SU-8 thick photoresist processing as a functional material for MEMS applications. J. Micromech. Microeng. 2002, 12, 368.

Rayleigh, L. XXV. On copying diffraction-gratings, and on some phenomena connected therewith. London Edinburgh Dublin Philos. Mag. J. Sci. 1881, 11, 196–205.

Talbot, H. F. LXXVI. Facts relating to optical science. No. IV. London Edinburgh Dublin Philos. Mag. J. Sci. 1836, 9, 401–407.

Sato, T. Talbot effect immersion lithography by self-imaging of very fine grating patterns. J. Vac. Sci. Technol. B 2012, 30, 06FG02.

Wen, J. M.; Zhang, Y.; Xiao, M. The Talbot effect: Recent advances in classical optics, nonlinear optics, and quantum optics. Adv. Opt. Photonics 2013, 5, 83–130.

Park, J.; Kim, K. I.; Kim, K.; Kim, D. C.; Cho, D.; Lee, J. H.; Jeon, S. Rapid, high-resolution 3D interference printing of multilevel ultralong nanochannel arrays for high-throughput nanofluidic transport. Adv. Mater. 2015, 27, 8000–8006.

Park, J.; Wang, S. D.; Li, M.; Ahn, C.; Hyun, J. K.; Kim, D. S.; Kim, D. K.; Rogers, J. A.; Huang, Y. G.; Jeon, S. Three-dimensional nanonetworks for giant stretchability in dielectrics and conductors. Nat. Commun. 2012, 3, 916.

Hyun, J. K.; Park, J.; Kim, E.; Lauhon, L. J.; Jeon, S. Rational control of diffraction and interference from conformal phase gratings: Toward high-resolution 3D nanopatterning. Adv. Opt. Mater. 2014, 2, 1213–1220.

Shir, D.; Liao, H. W.; Jeon, S.; Xiao, D.; Johnson, H. T.; Bogart, G. R.; Bogart, K. H. A.; Rogers, J. A. Three-dimensional nanostructures formed by single step, two-photon exposures through elastomeric Penrose quasicrystal phase masks. Nano Lett. 2008, 8, 2236–2244.

Nam, S. H.; Park, J.; Jeon, S. Rapid and large-scale fabrication of full color woodpile photonic crystals via interference from a conformal multilevel phase mask. Adv. Funct. Mater. 2019, 29, 1904971.

Jeon, S.; Malyarchuk, V.; Rogers, J. A.; Wiederrecht, G. P. Fabricating three dimensional nanostructures using two photon lithography in a single exposure step. Opt. Express 2006, 14, 2300–2308.

Jeon, S.; Shir, D. J.; Nam, Y. S.; Nidetz, R.; Highland, M.; Cahill, D. G.; Rogers, J. A.; Su, M. F.; El-Kady, I. F.; Christodoulou, C. G. et al. Molded transparent photopolymers and phase shift optics for fabricating three dimensional nanostructures. Opt. Express 2007, 15, 6358–6366.

Park, J.; Park, J. H.; Kim, E.; Ahn, C. W.; Jang, H. I.; Rogers, J. A.; Jeon, S. Conformable solid-index phase masks composed of high-aspect-ratio micropillar arrays and their application to 3D Nanopatterning. Adv. Mater. 2011, 23, 860–864.

del Campo, A.; Greiner, C. SU-8: A photoresist for high-aspect-ratio and 3D submicron lithography. J. Micromech. Microeng. 2007, 17, R81.

Lee, J. B.; Choi, K. H.; Yoo, K. Innovative SU-8 lithography techniques and their applications. Micromachines 2015, 6, 1–18.

Moon, J. H.; Yang, S. Chemical aspects of three-dimensional photonic crystals. Chem. Rev. 2010, 110, 547–574.

Moon, J. H.; Yang, S. Creating three-dimensional polymeric microstructures by multi-beam interference lithography. J. Macromol. Sci. Part C 2005, 45, 351–373.

Moon, J. H.; Ford, J.; Yang, S. Fabricating three-dimensional polymeric photonic structures by multi-beam interference lithography. Polym. Adv. Technol. 2006, 17, 83–93.

Hayek, A.; Xu, Y. A.; Okada, T.; Barlow, S.; Zhu, X. L.; Moon, J. H.; Marder, S. R.; Yang, S. Poly(glycidyl methacrylate)s with controlled molecular weights as low-shrinkage resins for 3D multibeam interference lithography. J. Mater. Chem. 2008, 18, 3316–3318.

Cho, D.; Park, J.; Kim, J.; Kim, T.; Kim, J.; Park, I.; Jeon, S. Three-dimensional continuous conductive nanostructure for highly sensitive and stretchable strain sensor. ACS Appl. Mater. Interfaces 2017, 9, 17369–17378.

Jang, J. H.; Jhaveri, S. J.; Rasin, B.; Koh, C. Y.; Ober, C. K.; Thomas, E. L. Three-dimensionally-patterned submicrometer-scale hydrogel/air networks that offer a new platform for biomedical applications. Nano Lett. 2008, 8, 1456–1460.

Jang, J. H.; Dendukuri, D.; Hatton, T. A.; Thomas, E. L.; Doyle, P. S. A route to three-dimensional structures in a microfluidic device: Stop-flow interference lithography. Angew. Chem., Int. Ed. 2007, 119, 9185–9189.

Moon, J. H.; Seo, J. S.; Xu, Y. A.; Yang, S. Direct fabrication of 3D silica-like microstructures from epoxy-functionalized polyhedral oligomeric silsesquioxane (POSS). J. Mater. Chem. 2009, 19, 4687–4691.

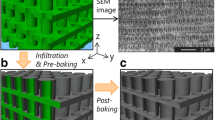

George, M. C.; Nelson, E. C.; Rogers, J. A.; Braun, P. V. Direct fabrication of 3D periodic inorganic microstructures using conformal phase masks. Angew. Chem., Int. Ed. 2008, 121, 150–154.

Park, J.; Seo, J.; Jung, H. K.; Hyun, G.; Park, S. Y.; Jeon, S. Direct optical fabrication of fluorescent, multilevel 3D nanostructures for highly efficient chemosensing platforms. Adv. Funct. Mater. 2016, 26, 7170–7177.

Ahn, C.; Park, J.; Kim, D.; Jeon, S. Monolithic 3D titania with ultrathin nanoshell structures for enhanced photocatalytic activity and recyclability. Nanoscale 2013, 5, 10384–10389.

Hyun, G.; Song, J. T.; Ahn, C.; Ham, Y.; Cho, D.; Oh, J.; Jeon, S. Hierarchically porous Au nanostructures with interconnected channels for efficient mass transport in electrocatalytic CO2 reduction. Proc. Natl. Acad. Sci. USA 2020, 117, 5680–5685.

Ahn, J.; Ahn, C.; Jeon, S.; Park, J. Atomic layer deposition of inorganic thin films on 3D polymer nanonetworks. Appl. Sci. 2019, 9, 1990.

Ahn, J.; Hong, S.; Shim, Y. S.; Park, J. Electroplated functional materials with 3D nanostructures defined by advanced optical lithography and their emerging applications. Appl. Sci. 2020, 10, 8780.

Novak, T. G.; Kim, K.; Jeon, S. 2D and 3D nanostructuring strategies for thermoelectric materials. Nanoscale 2019, 11, 19684–19699.

Cho, D.; Park, J.; Kim, T.; Jeon, S. Recent advances in lithographic fabrication of micro-/nanostructured polydimethylsiloxanes and their soft electronic applications. J. Semicond. 2019, 40, 111605.

Lee, K.; Yoon, H.; Ahn, C.; Park, J.; Jeon, S. Strategies to improve the photocatalytic activity of TiO2: 3D nanostructuring and heterostructuring with graphitic carbon nanomaterials. Nanoscale 2019, 11, 7025–7040.

Ahn, C.; Park, J.; Jeon, S. Recent advances in high-performance functional ceramics using 3D nanostructuring techniques. Ceramist 2019, 22, 230–242.

Moharam, M. G.; Gaylord, T. K. Rigorous coupled-wave analysis of grating diffraction—E-mode polarization and losses. J. Opt. Soc. Am. 1983, 73, 451–455.

Moharam, M. G.; Grann, E. B.; Pommet, D. A.; Gaylord, T. K. Formulation for stable and efficient implementation of the rigorous coupled-wave analysis of binary gratings. J. Opt. Soc. Am. A 1995, 12, 1068–1076.

Klein, W. R. Theoretical efficiency of Bragg devices. Proc. IEEE 1966, 54, 803–804.

Sullivan, D. M. Electromagnetic Simulation Using the FDTD Method, 2nd ed.; John Wiley & Sons: Hoboken, 2013.

Maria, J.; Malyarchuk, V.; White, J.; Rogers, J. A. Experimental and computational studies of phase shift lithography with binary elastomeric masks. J. Vac. Sci. Technol. B 2006, 24, 828–835.

Pouya, C.; Stavenga, D. G.; Vukusic, P. Discovery of ordered and quasi-ordered photonic crystal structures in the scales of the beetle Eupholus magnificus. Opt. Express 2011, 19, 11355–11364.

Bietsch, A.; Michel, B. Conformal contact and pattern stability of stamps used for soft lithography. J. Appl. Phys. 2000, 88, 4310–4318.

Schmid, H.; Michel, B. Siloxane polymers for high-resolution, high-accuracy soft lithography. Macromolecules 2000, 33, 3042–3049.

Truong, T. T.; Lin, R. S.; Jeon, S.; Lee, H. H.; Maria, J.; Gaur, A.; Hua, F.; Meinel, I.; Rogers, J. A. Soft lithography using acryloxy perfluoropolyether composite stamps. Langmuir 2007, 23, 2898–2905.

Guo, L. J. Nanoimprint lithography: Methods and material requirements. Adv. Mater. 2007, 19, 495–513.

Hui, C. Y.; Jagota, A.; Lin, Y. Y.; Kramer, E. J. Constraints on microcontact printing imposed by stamp deformation. Langmuir 2002, 18, 1394–1407.

Zhang, Y.; Lo, C. W.; Taylor, J. A.; Yang, S. Replica molding of high-aspect-ratio polymeric nanopillar arrays with high fidelity. Langmuir 2006, 22, 8595–8601.

Kwon, Y. W.; Park, J.; Kim, T.; Kang, S. H.; Kim, H.; Shin, J.; Jeon, S.; Hong, S. W. Flexible near-field nanopatterning with ultrathin, conformal phase masks on nonplanar substrates for biomimetic hierarchical photonic structures. ACS Nano 2016, 10, 4609–4617.

Park, J.; Tahk, D.; Ahn, C.; Im, S. G.; Choi, S. J.; Suh, K. Y.; Jeon, S. Conformal phase masks made of polyurethane acrylate with optimized elastic modulus for 3D nanopatterning. J. Mater. Chem. C 2014, 2, 2316–2322.

Kim, P.; Suh, K. Y. Rigiflex, spontaneously wettable polymeric mold for forming reversibly bonded nanocapillaries. Langmuir 2007, 23, 4549–4553.

Ministry of Technology. Adhesion Fundamentals and Practice; Macharen and Sons Ltd: London, 19

Hong, S.; Park, J.; Jeon, S. G.; Kim, K.; Park, S. H.; Shin, H. S.; Kim, B.; Jeon, S.; Song, J. Y. Monolithic Bi1.5Sb0.5Te3 ternary alloys with a periodic 3D nanostructure for enhancing thermoelectric performance. J. Mater. Chem. C 2017, 5, 8974–8980.

Cho, S.; Ahn, C.; Park, J.; Jeon, S. 3D nanostructured N-doped TiO2 photocatalysts with enhanced visible absorption. Nanoscale 2018, 10, 9747–9751.

Yoon, H.; Lee, K.; Kim, H.; Park, M.; Novak, T. G.; Hyun, G.; Jeong, M. S.; Jeon, S. Highly efficient UV-visible photocatalyst from monolithic 3D titania/graphene quantum dot heterostructure linked by aminosilane. Adv. Sustain. Syst. 2019, 3, 1900084.

Cho, D.; Suh, J. M.; Nam, S. H.; Park, S. Y.; Park, M.; Lee, T. H.; Choi, K. S.; Lee, J.; Ahn, C.; Jang, H. W. Optically activated 3D thin-shell TiO2 for super-sensitive chemoresistive responses: Toward visible light activation. Adv. Sci. 2021, 8, 2001883.

Kim, K.; Park, J.; Hong, S.; Park, S. H.; Jeon, S. G.; Ahn, C.; Song, J. Y.; Jeon, S. Anomalous thermoelectricity of pure ZnO from 3D continuous ultrathin nanoshell structures. Nanoscale 2018, 10, 3046–3052.

Tiwari, A. P.; Lee, K.; Kim, K.; Kim, J.; Novak, T. G.; Jeon, S. Conformally coated nickel phosphide on 3D, ordered nanoporous nickel for highly active and durable hydrogen evolution. ACS Sustainable Chem. Eng. 2020, 8, 17116–17123.

Kim, H.; Yun, S.; Kim, K.; Kim, W.; Ryu, J.; Nam, H. G.; Han, S. M.; Jeon, S.; Hong, S. Breaking the elastic limit of piezoelectric ceramics using nanostructures: A case study using ZnO. Nano Energy 2020, 78, 105259.

Kim, K.; Tiwari, A. P.; Hyun, G.; Novak, T. G.; Jeon, S. Improving electrochemical active area of MoS2 via attached on 3D-ordered structures for hydrogen evolution reaction. Int. J. Hydrog. Energy 2019, 44, 28143–28150.

Kuk, S. K.; Ham, Y.; Gopinath, K.; Boonmongkolras, P.; Lee, Y.; Lee, Y. W.; Kondaveeti, S.; Ahn, C.; Shin, B.; Lee, J. K. et al. Continuous 3D titanium nitride nanoshell structure for solar-driven unbiased biocatalytic CO2 reduction. Adv. Energy Mater. 2019, 9, 1900029.

Hyun, G.; Cho, S. H.; Park, J.; Kim, K.; Ahn, C.; Tiwari, A. P.; Kim, I. D.; Jeon, S. 3D ordered carbon/SnO2 hybrid nanostructures for energy storage applications. Electrochim. Acta 2018, 288, 108–114.

Kim, S.; Ahn, C.; Cho, Y.; Hyun, G.; Jeon, S.; Park, J. H. Suppressing buoyant force: New avenue for long-term durability of oxygen evolution catalysts. Nano Energy 2018, 54, 184–191.

Kim, K; Tiwari, A. P.; Novak, T. G.; Jeon, S. 3D ordered nanoelectrodes for energy conversion applications: Thermoelectric, piezoelectric, and electrocatalytic applications. J. Korean Ceram. Soc., in press, DOI: https://doi.org/10.1007/s43207-021-00113-9.

Cho, D.; Shim, Y. S.; Jung, J. W.; Nam, S. H.; Min, S.; Lee, S. E.; Ham, Y.; Lee, K.; Park, J.; Shin, J. et al. High-contrast optical modulation from strain-induced nanogaps at 3D heterogeneous interfaces. Adv. Sci. 2020, 7, 1903708.

Ahn, C.; Kim, S. M.; Jung, J. W.; Park, J.; Kim, T.; Lee, S. E.; Jang, D.; Hong, J. W.; Han, S. M.; Jeon, S. Multifunctional polymer nanocomposites reinforced by 3D continuous ceramic nanofillers. ACS Nano 2018, 12, 9126–9133.

Araki, S.; Ishikawa, Y.; Wang, X. D. F.; Uenuma, M.; Cho, D.; Jeon, S.; Uraoka, Y. Fabrication of nanoshell-based 3D periodic structures by templating process using solution-derived ZnO. Nanoscale Res. Lett. 2017, 12, 419.

Na, Y. E.; Shin, D.; Kim, K.; Ahn, C.; Jeon, S.; Jang, D. Emergence of new density-strength scaling law in 3D hollow ceramic nanoarchitectures. Small 2018, 14, 1802239.

Bae, G.; Choi, G. M.; Ahn, C.; Kim, S. M.; Kim, W.; Choi, Y.; Park, D.; Jang, D.; Hong, J. W.; Han, S. M. et al. Flexible protective film: Ultrahard, yet flexible hybrid nanocomposite reinforced by 3D inorganic nanoshell structures. Adv. Funct. Mater., in press, DOI: https://doi.org/10.1002/adfm.202010254.

Bae, G.; Jang, D.; Jeon, S. Scalable fabrication of high-performance thin-shell oxide nanoarchitected materials via proximity-field nanopatterning. ACS Nano, in press, DOI: https://doi.org/10.1021/acsnano.0c10534.

Kim, T.; Park, J.; Sohn, J.; Cho, D.; Jeon, S. Bioinspired, highly stretchable, and conductive dry adhesives based on 1D-2D hybrid carbon nanocomposites for all-in-one ECG electrodes. ACS Nano 2016, 10, 4770–4778.

Cho, D.; Jang, J. S.; Nam, S. H.; Ko, K.; Hwang, W.; Jung, J. W.; Lee, J.; Choi, M.; Hong, J. W.; Kim, I. D. Focused electric-field polymer writing: Toward ultralarge, multistimuli-responsive membranes. ACS Nano 2020, 14, 12173–12183.

Chen, H. M.; Jing, Y.; Lee, J. H.; Liu, D.; Kim, J.; Chen, S.; Huang, K.; Shen, X.; Zheng, Q. B.; Yang, J. L. et al. Human skin-inspired integrated multidimensional sensors based on highly anisotropic structures. Mater. Horiz. 2020, 7, 2378–2389.

Jang, H. I.; Ko, S.; Park, J.; Lee, D. E.; Jeon, S.; Ahn, C. W.; Yoo, K. S.; Park, J. H. Reversible creation of nanostructures between identical or different species of materials. Appl. Phys. A 2012, 108, 41–52.

Montoya, J. C.; Chang, C. H.; Heilmann, R. K.; Schattenburg, M. L. Doppler writing and linewidth control for scanning beam interference lithography. J. Vac. Sci. Technol. B 2005, 23, 2640–2645.

Yuan, L.; Herman, P. R. Laser scanning holographic lithography for flexible 3D fabrication of multi-scale integrated nano-structures and optical biosensors. Sci. Rep. 2016, 6, 22294.

Chen, I. T.; Schappell, E.; Zhang, X. L.; Chang, C. H. Continuous roll-to-roll patterning of three-dimensional periodic nanostructures. Microsyst. Nanoeng. 2020, 6, 22.

Jeon, S.; Nam, Y. S.; Shir, D. J. L.; Rogers, J. A.; Hamza, A. Three dimensional nanoporous density graded materials formed by optical exposures through conformable phase masks. Appl. Phys. Lett. 2006, 89, 253101.

Nam, Y. S.; Jeon, S.; Shir, D. J. L.; Hamza, A.; Rogers, J. A. Thick, three-dimensional nanoporous density-graded materials formed by optical exposures of photopolymers with controlled levels of absorption. Appl. Opt. 2007, 46, 6350–6354.

Zhou, H.; Ye, Q.; Xu, J. W. Polyhedral oligomeric silsesquioxane-based hybrid materials and their applications. Mater. Chem. Front. 2017, 1, 212–230.

Rinne, J. W.; Gupta, S.; Wiltzius, P. Inverse design for phase mask lithography. Opt. Express 2008, 16, 663–670.

Rolland, J. P.; Hagberg, E. C.; Denison, G. M.; Carter, K. R.; De Simone, J. M. High-resolution soft lithography: Enabling materials for nanotechnologies. Angew. Chem., Int. Ed. 2004, 43, 5796–5799.

Ahn, J.; Ahn, J.; Park, J. 3D-ordered porous composite microparticles formed via substrate-free optical 3D lithography. Funct. Compos. Struct. 2020, 2, 045007.

Matsukawa, K.; Watanabe, M.; Hamada, T.; Nagase, T.; Naito, H. Polysilsesquioxanes for gate-insulating materials of organic thin-film transistors. Int. J. Polym. Sci. 2012, 2012, 852063.

Acknowledgements

This research was supported by Creative Materials Discovery Program through the National Research Foundation of Korea (NRF) funded by Ministry of Science and ICT (No. 2020M3D1A1110522).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Nam, SH., Hyun, G., Cho, D. et al. Fundamental principles and development of proximity-field nanopatterning toward advanced 3D nanofabrication. Nano Res. 14, 2965–2980 (2021). https://doi.org/10.1007/s12274-021-3428-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-021-3428-6