Abstract

Fiber extracted from two species of jute, Corchorus olitorius (tossa) and Corchorus capsularis (white), is chemically treated with different concentrations (1–6 wt%) of NaOH. Chemical composition, crystallinity, fineness, whiteness, surface morphology, mechanical strength, and thermal stability of both untreated and treated fibers from both jute species are studied. The effects of alkali treatments on the two jute species are characterized using chemical composition analysis, Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), X-ray diffraction (XRD), digital fiber fineness tester, photovoltmeter, universal testing machine (UTM), and thermogravimetric analyzer (TGA). Based on the comprehensive findings, the optimal NaOH treatment concentration was determined to be 5%. The 5% NaOH treatment on both species showed improvements in cellulose content (tossa 13.08%, white 12.88%), crystallinity (tossa 7.81%, white 8.09%), and single fiber strength (tossa 58.61%, white 72.22%). The higher mechanical strength of tossa fiber compared to white jute fiber indicates its potential for composite preparation. On the other hand, the comparatively thinner white jute fiber, when compared to tossa jute fiber, is suitable for blending with cotton or man-made fibers.

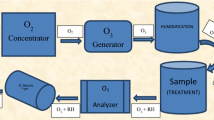

Graphical Abstract

Similar content being viewed by others

Data Availability

Raw data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

R. Ahmad, R. Hamid, S.A. Osman, Physical and chemical modifications of plant fibres for reinforcement in cementitious composites. Adv Civil Eng (2019). https://doi.org/10.1155/2019/5185806

A.A. Ullahand, A.B.M. Foisal, A review on sustainable textile products from jute and cotton blends. SEU J Sci Eng 13(1), 7–12 (2019)

Ali A. 2013. “Surface Modification of Hemp Fiber to Improve Spinning Properties.”

Y. Arao, T. Fujiura, S. Itani, T. Tanaka, Strength improvement in injection-molded jute-fiber-reinforced polylactide green-composites. Compos. B Eng. 68, 200–206 (2015)

A. Barreto, M.A. Esmeraldo, D. Rosa, P. Fechine, S. Mazzetto, Cardanol biocomposites reinforced with jute fiber: microstructure, biodegradability, and mechanical properties. Polym. Compos. 31, 1928–1937 (2010)

N. Bheel, S. Sohu, P. Awoyera, A. Kumar, S.A. Abbasi, O.B. Olalusi, Effect of wheat straw ash on fresh and hardened concrete reinforced with jute fiber. Adv Civ Eng (2021). https://doi.org/10.1155/2021/6659125

S.K. Chakrabarti, B.S. Ghosh, A.B. Kundu, B.L. Ghosh, Improvement in brightness and fineness of jute fibre by treatment with EDTA and polysaccharide-degrading enzymes. Indian J. Fibre Text. Res. 16(2), 154–158 (1991)

D. Cho, J.M. Kim, I.S. Song, I. Hong, Effect of alkali pre-treatment of jute on the formation of jute-based carbon fibers. Mater. Lett. 65(10), 1492–1494 (2011)

J.A. Cottrell, M. Ali, A. Tatari, D. Brett Martinson, Effects of fibre moisture content on the mechanical properties of jute reinforced compressed earth composites. Constr. Build. Mater. 373, 130848 (2023)

S. Das, A.K. Singha, A. Chaudhuri, P.K. Ganguly, Lengthwise jute fibre properties variation and its effect on jute-polyester composite. J. Text. Inst. 110(12), 1695–1702 (2019)

M.D.A.R. Dayan, M.M. Rahman, J. Ferdush, M.A. Kaysar, M. Uddin, Effect of harvesting time on the fiber yield and characterization of jute fiber. J Nat Fibers 19(15), 12434–12445 (2022)

V. Dorugade, M. Taye, S.A. Qureshi, T. Agazie, B. Seyoum, B. Abebe, S. Komarabathina, Agrotextiles: important characteristics of fibres and their applications–a review. J Nat Fibers (2023). https://doi.org/10.1080/15440478.2023.2211290

L. Duan, Yu. Weidong, Z. Li, Analysis of structural changes in jute fibers after peracetic acid treatment. J. Eng. Fibers Fabr. 12(1), 33–42 (2017)

A. Etale, A.J. Onyianta, S.R. Turner, S.J. Eichhorn, Cellulose: a review of water interactions, applications in composites, and water treatment. Chem. Rev. 123(5), 2016–2048 (2023)

M. Fan, D. Dai, B. Huang, Fourier transform infrared spectroscopy for natural fibres. Fourier Trans Mater Anal (2012). https://doi.org/10.5772/35482

R. Gogoi, A.K. Tyagi, Surface modification of jute fabric by treating with silane coupling agent for reducing its moisture regain characteristics. J Nat Fibers 18(6), 803–812 (2021)

B.K. Goriparthi, K.N.S. Suman, N.M. Rao, Effect of fiber surface treatments on mechanical and abrasive wear performance of polylactide/jute composites. Compos. A Appl. Sci. Manuf. 43(10), 1800–1808 (2012)

H. Gu, Tensile behaviours of the coir fibre and related composites after NaOH treatment. Mater. Des. 30(9), 3931–3934 (2009)

B.B. Haniel, P.W. Anggoro, Optimization of characteristics polymer composite reinforced kenaf and jute fiber using taguchi-response surface methodology approach. J Nat Fibers (2023). https://doi.org/10.1080/15440478.2023.2204453

M.Y. Hashim, A.M. Amin, O.M.F. Marwah, M.H. Othman, M.R.M. Yunus, N.C. Huat, The effect of alkali treatment under various conditions on physical properties of kenaf fiber. J. Phys. Conf. Ser. 914(1), 012030 (2017)

M.K. Hossain, M.W. Dewan, M. Hosur, S. Jeelani, Mechanical performances of surface modified jute fiber reinforced biopol nanophased green composites. Compos. B Eng. 42(6), 1701–1707 (2011)

M.S. Huda, L.T. Drzal, A.K. Mohanty, M. Misra, Effect of chemical modifications of the pineapple leaf fiber surfaces on the interfacial and mechanical properties of laminated biocomposites. Compos. Interfaces 15(2–3), 169–191 (2008)

M.S. Islam, J.A. Saito, E.M. Emdadul, B. Ahmed, M.M. Islam, A. Halim, Q.M. Hossen et al., Comparative genomics of two jute species and insight into fibre biogenesis. Nature Plants 3, 1–7 (2017)

M.H. Islam, M.R. Islam, M. Dulal, S. Afroj, N. Karim, The effect of surface treatments and graphene-based modifications on mechanical properties of natural jute fiber composites: a review. IScience 25(1), 103597 (2022)

S. Kavitha, R.K. Anne, K.P. Priya, S.A. Arunachalam, N. Maureira-Carsalade, Á. Roco-Videla, Investigation on properties of raw and alkali treated novel cellulosic root fibres of zea mays for polymeric composites. Polymers 15(7), 1–21 (2023)

J.A. Khan, M.A. Khan, The use of jute fibers as reinforcements in composites. Biofiber reinforcements in composite materials (Elsevier, New York, 2015)

J.A. Khan, M.A. Khan, R. Islam, Effect of mercerization on mechanical, thermal and degradation characteristics of jute fabric-reinforced polypropylene composites. Fibers Polym 13(10), 1300–1309 (2012)

A. Kovačević, M. Radoičić, D. Marković, M. Ponjavić, J. Nikodinovic-Runic, M. Radetić, Non-woven sorbent based on recycled jute fibers for efficient oil spill clean-up: from production to biodegradation. Environ. Technol. Innov. 31, 103170 (2023)

A. Lakshmanan, R.K. Ghosh, S. Dasgupta, S. Chakraborty, P.K. Ganguly, Optimization of alkali treatment condition on jute fabric for the development of rigid biocomposite. J. Ind. Text. 47(5), 640–655 (2018)

X. Li, L.G. Tabil, S. Panigrahi, Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J. Polym. Environ. 15(1), 25–33 (2007)

M.O.S. Lobregas, E.V.D. Buniao, J.L. Leaño, Alkali-enzymatic treatment of bambusa blumeana textile fibers for natural fiber-based textile material production. Ind. Crops Prod. 194, 116268 (2023)

T. Paridah Md, A.B. Ahmed, S.O.A. SaifulAzry, Z. Ahmed, Retting process of some bast plant fibres and its effect on fibre quality: a review. BioResources 6(4), 5260–5281 (2011)

J.I. Mir, P.G. Karmakar, S. Chattopadhyay, S.K. Chaudhury, S.K. Ghosh, A. Roy, SSR and RAPD profile based grouping of selected jute germplasm with respect to fibre fineness trait. J. Plant Biochem. Biotechnol. 17(1), 29–35 (2008)

Y. Pathan, G.B. Veeresh Kumar, Potential of agave angustifolia marginata for composite and textile applications—a new source of natural fibre. Ind. Crops Prod. 203, 117213 (2023)

Z. Qin, S. Zhao, L. Liu, Z. Shi, L. Cheng, R. Zhang, Isolation and characterization of lignocellulosic fiber from jute bast by the organic solvent degumming system: an alkali-free method. Text. Res. J. 91(23–24), 2757–2770 (2021)

V. Rajulapati, D. Arun, K.G. Kiran, K. Vimal, G. Arun, Green bioprocess of degumming of jute fibers and bioscouring of cotton fabric by recombinant pectin methylesterase and pectate lyases from clostridium thermocellum. Process Biochem. 92, 93–104 (2020)

D. Ray, M. Das, D. Mitra, A comparative study of the stress-relaxation behavior of untreated and alkali-treated jute fibers. J. Appl. Polym. Sci. 123, 1348–1358 (2012)

D. Ray, B.K. Sarkar, R.K. Basak, A.K. Rana, Study of the thermal behavior of alkali-treated jute fibers. J. Appl. Polym. Sci. 85(12), 2594–2599 (2002)

D. Ray, B.K. Sarkar, Characterization of alkali-treated jute fibers for physical and mechanical properties. J. Appl. Polym. Sci. 80(7), 1013–1020 (2001)

E.S. Rodriguez, P.M. Stefani, A. Vazquez, Effects of fibers’ alkali treatment on the resin transfer molding processing and mechanical properties of jute-vinylester composites. J. Compos. Mater. 41(14), 1729–1741 (2007)

J. Ronald Aseer, K. Sankaranarayanasamy, P. Jayabalan, R. Natarajan, K. Priya Dasan, Morphological, physical, and thermal properties of chemically treated banana fiber. J Nat Fibers 10(4), 365–380 (2013)

I.M. Rosa, J.M. De, D.P. Kenny, C. Santulli, F. Sarasini, Morphological, thermal and mechanical characterization of okra (abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos. Sci. Technol. 70(1), 116–122 (2010)

Roy Sudripta and International Jute Study Group. 2010. Jute Basics. TA - TT -. 1st ed. Dhaka SE: International Jute Study Group.

A.K. Sahi, M.K. Singh, A. Das, Effect of enzymatic process on characteristics of cottonized industrial hemp fibre. Indian J. Fibre Text. Res. 47(3), 281–289 (2022)

S.M.M. Alamgir, Comparison between tensile and damage analysis of hybrid jute/polypropylene needlepunched nonwoven geotextiles produced from untreated and alkali treated jute fibers. J. Text. Inst. 110(12), 1800–1809 (2019)

S.M.M. Alamgir, A. Paharia, Optimisation of the surface treatment of jute fibres for natural fibre reinforced polymer composites using weibull analysis. J. Text. Inst. 110(11), 1588–1595 (2019)

K. Sever, M. Sarikanat, Y. Seki, G. Erkan, Ü.H. Erdoĝan, S. Erden, Surface treatments of jute fabric: the influence of surface characteristics on jute fabrics and mechanical properties of jute/polyester composites. Ind. Crops Prod. 35(1), 22–30 (2012)

I. Shah, Li. Jing, Z.M. Fei, Y.S. Yuan, M.U. Farooq, N. Kanjana, A Review on chemical modification by using sodium hydroxide (NaOH) to investigate the mechanical properties of sisal, coir and hemp fiber reinforced concrete composites. J Nat Fibers 19(13), 5133–5151 (2022)

J.I. Singh, S.S. Preet, V. Dhawan, Effect of alkali treatment on mechanical properties of jute fiber-reinforced partially biodegradable green composites using epoxy resin matrix. Polym. Polym. Compos. 28(6), 388–397 (2020)

E. Sinha, S.K. Rout, Influence of fibre-surface treatment on structural, thermal and mechanical properties of jute fibre and its composite. Bull. Mater. Sci. 32(1), 65–76 (2009)

I. Taha, L. Steuernagel, G. Ziegmann, Optimization of the alkali treatment process of date palm fibres for polymeric composites. Compos. Interfac 14(7–9), 669–684 (2007)

M.D. Teli, S.P. Valia, Acetylation of jute fiber to improve oil absorbency. Fibers Poly 14(6), 915–919 (2013)

A.G. Tesfay, M.B. Kahsay, P.S. Senthil Kumar, Effect of carbon and glass fillers on tensile and impact strength, water absorption, and degradation properties of sisal/polyester composites. J Nat Fibers (2023). https://doi.org/10.1080/15440478.2023.2202886

H. Wang, H. Memon, E.A.M. Hassan, M.S. Miah, M.A. Ali, Effect of jute fiber modification on mechanical properties of jute fiber composite. Materials 12(8), 1226 (2019)

W. Wang, Xu. Meng, J. Lou, A. Dong, Changes in physicomechanical properties and structures of jute fibers after tetraacetylethylenediamine activated hydrogen peroxide treatment. J. Market. Res. 9(6), 15412–15420 (2020)

W. Yi-Xian, G. Pan-Pan, R. Wei-Xin, Y. Bing-Xiang, Y. Hai-Ping, Z. Yan-Lin, S. Sheng-Biao, C. Ping, Laboratory investigation on strength characteristics of expansive soil treated with jute fiber reinforcement. Int. J. Geomech. 17(11), 4017101 (2017)

S.B. Youbi, N.R. Tchinwoussi, S. Tagne, O. Harzallah, P.W.M. Huisken, T.T. Stanislas, E. Njeugna, J.-Y. Drean, S. Bistac-Brogly, Effect of alkali and silane treatments on the surface energy and mechanical performances of raphia vinifera fibres. Ind. Crops Prod. 190, 115854 (2022)

M.T. Zafar, S.N. Maiti, A.K. Ghosh, Effect of surface treatment of jute fibers on the interfacial adhesion in poly(lactic acid)/jute fiber biocomposites. Fibers Polym 17(2), 266–274 (2016)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaysar, M.A., Ahmed, S.J., Jamil, A.T.M.K. et al. Impact of NaOH Treatment on the Chemical, Structural, Physico-mechanical, and Thermal Characteristics of Jute Species. Fibers Polym 25, 1765–1777 (2024). https://doi.org/10.1007/s12221-024-00542-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-024-00542-3