Abstract

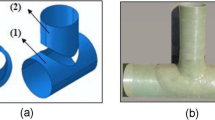

Joints are the weakest links in the composite pipes under internal pressure due to the discontinuity of reinforcement in connection area. Weft-knitted integrated preforms can be used to enhance the strength of these composite joints. The focus of this study is to develop a geometrical model for the finite element analysis of composite joints reinforced with single jersey weft knitted fabric, which take cylindrical forms. Thus our efforts are concentrated on generating geometrical models for weft-knitted integrated preforms as reinforcement of Tee-joint, and various Wye-joint composites in pipelines. A geometrical model was first developed for loops on the curved surfaces by modifying the offered model for loops on flat surfaces. Then, the joint was divided into two cylinders; main cylinder and joint. Each cylinder was modeled using the generated model for loops on curved surfaces. The modeled cylinders were assembled according to the structure of joints. A python algorithm was proposed to simulate the weft-knitted integrated preforms in Abaqus/CAE 2016 commercial package. By implementing the proposed algorithm, the geometry of reinforcement was modeled for three types of joints based on technical data of ASME-B31. To verify the generated model, T-shape weft knitted integrated preform was produced using glass yarn count of 220 tex, CPC and WPC of 6 and 4, respectively. Comparing the experiment and simulation results shows a maximum error percentage of 10 % in the predicting the structural parameters of joints. It can be concluded that the generated model can well predict the geometry of weft-knitted preforms.

Similar content being viewed by others

References

C. M. Pastore, A. E. Bogdanovich, and Y. A. Gowayed, Compos. Part B-Eng, 3, 181 (1993).

S. Adanur and T. Liao, Compos. Part B-Eng., 29, 787 (1998).

M. D. Araujo, R. Fangueiro, and H. Hong, AUTEX Res. J., 4, 72 (2004).

H. Lin, X. Zeng, M. Sherburn, A. C. Long, and M. J. Clifford, Text. Res. J., 82, 1689 (2012).

Y. Kyosev, Text. Res. J., 86, 1270 (2015).

T. C. Lim, S. Ramakrishna, and H. M. Shang, Proc. Inst. Mech. Eng. B. J. Eng. Manuf., 214, 333 (2000).

J. Hofstee and F. van Keulen, Compos. Struct., 54, 179 (2001).

A. Cherouat, H. Borouchaki, and J. L. Billoet, Eur. J. Comput. Mech., 14, 693 (2005).

P. Potluri, S. Sharma, and R. Ramgulam, Compos. Part A Appl., 32, 1415 (2001).

G. A. V. Leaf and A. Glaskin, J. Text. Inst., 46, 587 (1955).

S. G. Vassiliadis, A. E. Kallivretaki, and C. G. Provatidis, Indian J. Fibre Text., 32, 62 (2007).

D. Semnani, M. Latifi, S. Hamzeh, and A. A. A. Jeddi, J. Text. Inst., 94, 202 (2003).

A. Kurbak and O. Ekmen, Text. Res. J., 78, 198 (2008).

A. Kurbak and O. Kaycan, Text. Res. J., 78, 279 (2008).

A. Kurbak and A. S. Soydan, Text. Res. J., 78, 377 (2008).

O. Kayacan and A. Kurbak, Text. Res. J., 78, 659 (2008).

A. Kurbak and O. Kaycan, Text. Res. J., 78, 577 (2008).

A. Kurbak, Text. Res. J., 79, 418 (2009).

A. Kurbak and T. Alpyildiz, Text. Res. J., 79, 495 (2009).

A. Kurbak and A. S. Soydan, Text. Res. J., 79, 618 (2009).

A. Kurbak, Text. Res. J., 87, 838 (2016).

A. Kurbak, Text. Res. J., 87, 409 (2016).

W. Renkens and Y. Kyosev, Text. Res. J., 81, 437 (2011).

Y. Ji, G. Jiang, M. Tang, N. Mao, and H. Wang, Text. Res. J., 90, 2639 (2020).

M. J. Abghary, H. Hasani, and R. J. Nedoushan, Fiber. Polym., 17, 795 (2016).

Y. Kyosev, Y. Angelova, and R. Kovar, Res. J. Text. Apparel, 9, 88 (2005).

Acknowledgement

This research has been funded by Amirkabir University of Technology (Tehran Polytechnic) via grant number of 11893.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Ghatrenabi, M.H., Dabiryan, H. & Nosraty, H. Modeling the Geometry of Weft-knitted Integrated Preforms as Reinforcement of Composite Joints. Fibers Polym 22, 2572–2580 (2021). https://doi.org/10.1007/s12221-021-1180-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-021-1180-x