Abstract

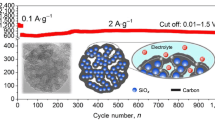

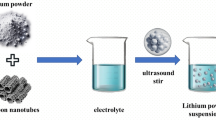

Silicon (Si) is a potential high-capacity anode material for the next-generation lithium-ion battery with high energy density. However, Si anodes suffer from severe interfacial chemistry issues, such as side reactions at the electrode/electrolyte interface, leading to poor electrochemical cycling stability. Herein, we demonstrate the fabrication of a conformal fluorine-containing carbon (FC) layer on Si particles (Si-FC) and its in situ electrochemical conversion into a LiF-rich carbon layer above 1.5 V (vs. Li+/Li). The as-formed LiF-rich carbon layer not only isolates the active Si and electrolytes, leading to the suppression of side reactions, but also induces the formation of a robust solid–electrolyte interface (SEI), leading to the stable interfacial chemistry of as-designed Si-FC particles. The Si-FC electrode has a high initial Coulombic efficiency (CE) of 84.8% and a high reversible capacity of 1450 mAh/g at 0.4 C (1000 mA/g) for 300 cycles. In addition, a hybrid electrode consisting of 85 wt% graphite and 15 wt% Si-FC, and mass 2.3 mg/cm2 loading delivers a high areal capacity of 2.0 mAh/cm2 and a high-capacity retention of 93.2% after 100 cycles, showing the prospects for practical use.

Graphical Abstract

Similar content being viewed by others

References

Armand M, Tarascon JM (2008) Building better batteries. Nature 451(7179):652–657

Crabtree G (2019) The coming electric vehicle transformation. Science 366(6464):422–424

Nitta N, Wu FX, Lee JT et al (2015) Li-ion battery materials: present and future. Mater Today 18(5):252–264. https://doi.org/10.1016/j.mattod.2014.10.040

Li M, Lu J, Chen ZW et al (2018) 30 years of lithium-ion batteries. Adv Mater 30(33):1800561. https://doi.org/10.1002/adma.201800561

Lu J, Chen ZW, Pan F et al (2018) High-performance anode materials for rechargeable lithium-ion batteries. Electrochem Energ Rev 1(1):35–53. https://doi.org/10.1007/s41918-018-0001-4

Tu SB, Su H, Sui D et al (2021) Mesoporous carbon nanomaterials with tunable geometries and porous structures fabricated by a surface-induced assembly strategy. Energy Storage Mater 35:602–609. https://doi.org/10.1016/j.ensm.2020.11.042

Sung J, Kim N, Ma J et al (2021) Subnano-sized silicon anode via crystal growth inhibition mechanism and its application in a prototype battery pack. Nat Energy 6(12):1164–1175

Tu SB, Ai X, Wang XC et al (2021) Circumventing chemo-mechanical failure of Sn foil battery anode by grain refinement and elaborate porosity design. J Energy Chem 62(11):477–484

Sun YM, Wang L, Li YB et al (2019) Design of red phosphorus nanostructured electrode for fast-charging lithium-ion batteries with high energy density. Joule 3(4):1080–1093. https://doi.org/10.1016/j.joule.2019.01.017

Tan DHS, Chen YT, Yang HD et al (2021) Carbon-free high-loading silicon anodes enabled by sulfide solid electrolytes. Science 373(6562):1494–1499

Prado AYR, Rodrigues MTF, Trask SE et al (2020) Electrochemical dilatometry of Si-bearing electrodes: dimensional changes and experiment design. J Electrochem Soc 167(16):160551. https://doi.org/10.1149/1945-7111/abd465

McDowell MT, Lee SW, Nix WD et al (2013) 25th anniversary article: understanding the lithiation of silicon and other alloying anodes for lithium-ion batteries. Adv Mater 25(36):4966–4985. https://doi.org/10.1002/adma.201301795

Stetson C, Yin YL, Jiang CS et al (2019) Temperature-dependent solubility of solid electrolyte interphase on silicon electrodes. ACS Energy Lett 4(12):2770–2775. https://doi.org/10.1021/acsenergylett.9b02082

Sina M, Alvarado J, Shobukawa H et al (2016) Direct visualization of the solid electrolyte interphase and its effects on silicon electrochemical performance. Adv Mater Interfaces 3(20):1600438. https://doi.org/10.1002/admi.201600438

He Y, Jiang L, Chen TW et al (2021) Progressive growth of the solid–electrolyte interphase towards the Si anode interior causes capacity fading. Nat Nanotechnol 16(10):1113–1120

Chan CK, Peng HL, Liu G et al (2008) High-performance lithium battery anodes using silicon nanowires. Nat Nanotechnol 3(1):31–35

Yao Y, McDowell MT, Ryu I et al (2011) Interconnected silicon hollow nanospheres for lithium-ion battery anodes with long cycle life. Nano Lett 11(7):2949–2954. https://doi.org/10.1021/nl201470j

Lu ZD, Liu N, Lee HW et al (2015) Nonfilling carbon coating of porous silicon micrometer-sized particles for high-performance lithium battery anodes. ACS Nano 9(3):2540–2547

Xu Q, Li JY, Sun JK et al (2016) Watermelon-inspired Si/C microspheres with hierarchical buffer structures for densely compacted lithium-ion battery anodes. Adv Energy Mater 7(3):1601481. https://doi.org/10.1002/aenm.201601481

Xu ZX, Yang J, Zhang T et al (2018) Silicon microparticle anodes with self-healing multiple network binder. Joule 2(5):950–961. https://doi.org/10.1016/j.joule.2018.02.012

Choi S, Kwon TW, Coskun A et al (2017) Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries. Science 357(6348):279–283

Qian CX, Zhao J, Sun YM et al (2020) Electrolyte-phobic surface for the next-generation nanostructured battery electrodes. Nano Lett 20(10):7455–7462

Shi WY, Wu HB, Baucom J et al (2020) Covalently bonded Si-polymer nanocomposites enabled by mechanochemical synthesis as durable anode materials. ACS Appl Mater Interfaces 12(35):39127–39134

Piper DM, Yersak TA, Son SB et al (2013) Conformal coatings of cyclized-PAN for mechanically resilient Si nano-composite anodes. Adv Energy Mater 3(6):697–702. https://doi.org/10.1002/aenm.201200850

Fang JB, Chang SZ, Ren Q et al (2021) Tailoring stress and ion-transport kinetics via a molecular layer deposition-induced artificial solid electrolyte interphase for durable silicon composite anodes. ACS Appl Mater Interfaces 13(27):32520–32530

Ai Q, Li DP, Guo JG et al (2019) Artificial solid electrolyte interphase coating to reduce lithium trapping in silicon anode for high performance lithium-ion batteries. Adv Mater Interfaces 6(21):1901187

Zhao L, Zhang DF, Huang YF et al (2021) Constructing a reinforced and gradient solid electrolyte interphase on Si nanoparticles by in-situ thiol-ene click reaction for long cycling lithium-ion batteries. Small 17(40):2102316. https://doi.org/10.1002/smll.202102316

Christensen J, Newman J (2004) A mathematical model for the lithium-ion negative electrode solid electrolyte interphase. J Electrochem Soc 151(11):A1977–A1988. https://doi.org/10.1149/1.1804812

Jones J, Anouti M, Caillon-Caravanier M et al (2009) Thermodynamic of LiF dissolution in alkylcarbonates and some of their mixtures with water. Fluid Phase Equilib 285(1–2):62–68. https://doi.org/10.1016/j.fluid.2009.07.020

Zhu YZ, He XF, Mo YF (2015) Origin of outstanding stability in the lithium solid electrolyte materials: insights from thermodynamic analyses based on first-principles calculations. ACS Appl Mater Interfaces 7(42):23685–23693

Jia HP, Zou LF, Gao PY et al (2019) High-performance silicon anodes enabled by nonflammable localized high-concentration electrolytes. Adv Energy Mater 9(31):1900784. https://doi.org/10.1002/aenm.201900784

Chen J, Fan XL, Li Q et al (2020) Electrolyte design for LiF-rich solid-electrolyte interfaces to enable high-performance microsized alloy anodes for batteries. Nat Energy 5(5):386–397. https://doi.org/10.1038/s41560-020-0601-1

Pan J, Cheng YT, Qi Y (2015) General method to predict voltage-dependent ionic conduction in a solid electrolyte coating on electrodes. Phys Rev B 91(13):1773–1783. https://doi.org/10.1103/PhysRevB.91.134116

Sayahpour B, Hirsh H, Bai S et al (2022) Revisiting discharge mechanism of CFx as a high energy density cathode material for lithium primary battery. Adv Energy Mater 12(5):2103196. https://doi.org/10.1002/aenm.202103196

Zhao J, Liao L, Shi FF et al (2017) Surface fluorination of reactive battery anode materials for enhanced stability. J Am Chem Soc 139(33):11550–11558

Acknowledgements

This work is supported by the Innovation Fund of Wuhan National Laboratory for Optoelectronics of Huazhong University of Science and Technology.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ni, Y., Tu, S., Zhan, R. et al. In Situ Formation of LiF-Rich Carbon Interphase on Silicon Particles for Cycle-Stable Battery Anodes. Trans. Tianjin Univ. 29, 101–109 (2023). https://doi.org/10.1007/s12209-022-00349-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-022-00349-4