Abstract

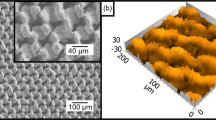

Superhydrophobic surfaces have emerged because of their unique properties like corrosion resistance, self-cleaning, anti-icing and being anti-bacterial. A simplistic and highly effective ultra-fast laser technology was used to fabricate superhydrophobic surface on aluminum substrate. Compared to other laser systems, picosecond laser systems have smaller thermal affected area on the aluminum substrate. They also offer high efficiency, not as much of waste materials and cover enormous areas for mass production. Tilted groove patterns of various angles with respect to horizontal were textured on the substrate by using picosecond laser pulses. The laser parameters, such as hatching distance (HD) and scanning speed (SS), can be varied by keeping the laser power as constant for the various tilted angle of the groove pattern. The textured surfaces were initially super hydrophilic when kept in polyethylene zip lock cover and which also exhibits super hydrophobicity of maximum 155.5° when observed after 15 days. The morphology of surface was characterized by scanning electron microscope, EDX and X-ray diffraction.

Similar content being viewed by others

References

S. S. Latthe, A. B. Gurav, C. S. Maruti and R. S. Vhatkar, Recent progress in preparation of superhydrophobic surfaces: A review, J. Surf. Eng. Mater. Adv. Technol., 2 (2012) 76–94.

W. Barthlott and C. Neinhuis, Purity of the sacred lotus, or escape from contamination in biological surfaces, Planta, 202 (1997) 1–8.

S. Wang and L. Jiang, Definition of superhydrophobic states, Advanced Materials (2007) 3423–3424.

A. Lafuma and D. Quéré, Superhydrophobic states, Nature Materials (2003) 457–460.

S. Jin, K. Kim and J. H. Jeong, Adhesion energy per unit area various liquid droplets on PMMA, Parylene C and PPFC coated flat solid surfaces, J. Mech. Sci. Technol., 33 (2019) 1441–1450.

J. W. Oh et al., Characteristics analysis of the developed surface modification technologies to improve the anti-corrosion performances for offshore equipments, J. of Mechanical Science and Technology, 33 (2019) 3971–3979.

P. Zhang and F. Y. Lv, A review of the recent advances in superhydrophobic surfaces and the emerging energy-related applications, Energy, 82 (2015) 1068–1087.

C. Chen et al., A green one-step fabrication of superhydrophobic metallic surfaces of aluminum and zinc, J. Alloys Compd., 711 (2017) 506–513.

J. Xiong, D. K. Sarkar and X. G. Chen, Superhydrophobic honeycomb-like cobalt stearate thin films on aluminum with excellent anti-corrosion properties, Appl. Surf. Sci., 407 (2017) 361–370.

A. Pendurthi et al., Fabrication of nanostructured omniphobic and superomniphobic surfaces with inexpensive CO2 laser engraver, ACS Appl. Mater. Interfaces, 9 (2017) 25656–25661.

S. F. Toosi, S. Moradi, M. Ebrahimi and S. G. Hatzikiriakos, Microfabrication of polymeric surfaces with extreme wettability using hot embossing, Appl. Surf. Sci., 378 (2016) 426–434.

Z. Zhang, B. Ge, X. Men and Y. Li, Mechanically durable, superhydrophobic coatings prepared by dual-layer method for anti-corrosion and self-cleaning, Colloids Surfaces A Physicochem. Eng. Asp., 490 (2016) 182–188.

J. Song et al., Ultrafast fabrication of rough structures required by superhydrophobic surfaces on Al substrates using an immersion method, Chem. Eng. J., 211-212 (2012) 143–152.

Y. Gao, Y. Sun and D. Guo, Facile fabrication of superhydrophobic surfaces with low roughness on Ti-6Al-4V substrates via anodization, Appl. Surf. Sci., 314 (2014) 754–759.

F. Y. Lv and P. Zhang, Fabrication and characterization of superhydrophobic surfaces on aluminum alloy substrates, Appl. Surf. Sci., 321 (2014) 166–172.

T. Xiang et al., Robust superhydrophobic coating with superior corrosion resistance, J. Alloys Compd., 798 (2019) 320–325.

T. Rezayi and M. H. Entezari, Toward a durable superhydrophobic aluminum surface by etching and ZnO nanoparticle deposition, J. Colloid Interface Sci., 463 (2016) 37–45.

H. Yang et al., Fabrication of a superhydrophobic and highglossy copper coating on aluminum substrates, Appl. Surf. Sci., 433 (2017) 1192–1196.

T. T. Isimjan, T. Wang and S. Rohani, A novel method to prepare superhydrophobic, UV resistance and anti-corrosion steel surface, Chem. Eng. J., 210 (2012) 182–187.

Y. Shen et al., Petal shaped nanostructures planted on array micro-patterns for superhydrophobicity and anti-icing applications, Surf. Coatings Technol., 319 (2017) 286–293.

Z. Lei et al., Large spot diameter nanosecond laser treatment of aluminum alloy sheets for high-speed superhydrophobic hierarchical micro- and nanostructured surface preparation, Surf. Coat. Technol., 361 (2019) 249–254.

A. Samanta, Q. Wang, S. K. Shaw and H. Ding, Nanostructuring of laser textured surface to achieve superhydrophobicity on engineering metal surface, J. Laser Appl., 31 (2019) 022515-1-7.

P. Pou et al., Laser texturing of stainless steel under different processing atmospheres: From superhydrophilic to superhydrophobic surfaces, Appl. Surf. Sci., 475 (2018) 896–905.

F. H. Rajab, Z. Liu and L. Li, Long term superhydrophobic and hybrid superhydrophobic/superhydrophilic surfaces produced by laser surface micro/nano surface structuring, Appl. Surf. Sci., 466 (2019) 808–821.

M. Zupančič, M. Može, P. Gregorčič and I. Golobič, Nanosecond laser texturing of uniformly and non-uniformly wettable micro structured metal surfaces for enhanced boiling heat transfer, Appl. Surf. Sci., 399 (2017) 480–490.

L. B. Boinovich et al., Corrosion behavior of superhydrophobic aluminum alloy in concentrated potassium halide solutions: When the specific anion effect is manifested, Corros. Sci., 112 (2016) 517–527.

Z. Yang, Y. L. Tian, C. J. Yang, F. J. Wang and X. P. Liu, Modification of wetting property of Inconel 718 surface by nanosecond laser texturing, Appl. Surf. Sci., 414 (2017) 313–324.

R. Jagdheesh, M. Diaz, S. Marimuthu and J. L. Ocana, Robust fabrication of μ-patterns with tunable and durable wetting properties: Hydrophilic to ultrahydrophobic via a vacuum process, J. Mater. Chem. A, 5 (2017) 7125–7136.

R. Jagdheesh, M. Diaz and J. L. Ocaña, Bio inspired selfcleaning ultrahydrophobic aluminium surface by laser processing, RSC Adv., 77 (2016) 72933–72941.

Q. Ma, Z. Tong, W. Wang and G. Dong, Fabricating robust and repairable superhydrophobic surface on carbon steel by nanosecond laser texturing for corrosion protection, Appl. Surf. Sci., 455 (2018) 748–757.

T. Young, An essay on the cohesion of fluids, Philos. Trans. R. Soc. London, 95 (1805) 65–87.

B. D. Cassie and S. Baxter, Wettability of porous surfaces, Transactions of the Faraday Society, 40 (1944).

C. J. Yang et al., Modification of wettability property of titanium by laser texturing, Int. J. Adv. Manuf. Technol., 87 (2016) 1663–1670.

J. T. Cardoso et al., Influence of ambient conditions on the evolution of wettability properties of an IR-, ns-laser textured aluminium alloy, RSC Adv., 63 (2017).

S. Peng and W. Deng, A simple method to prepare superamphiphobic aluminum surface with excellent stability, Colloids Surfaces A Physicochem. Eng. Asp., 481 (2015) 143–150.

J. Van den Brand, W. G. Sloof, H. Terryn and J. H. W. De Wit, Correlation between hydroxyl fraction and O/Al atomic ratio as determined from XPS spectra of aluminium oxide layers, Surf. Interface Anal., 36 (2014) 81–88.

J. Van Den Brand, S. Van Gils, P. C. J. Beentjes, H. Terryn and J. H. W. De Wit, Ageing of aluminium oxide surfaces and their subsequent reactivity towards bonding with organic functional groups, Appl. Surf. Sci., 235 (2004) 465–474.

S. Takeda, M. Fukawa, Y. Hayashi and K. Matsumoto, Surface OH group governing adsorption properties of metal oxide films, Thin Solid Films, 339 (1999) 220–224.

W. Xing et al., Anti-icing aluminum alloy surface with multilevel micro-nano textures constructed by picosecond laser, Mater. Des., 183 (2019) 108156.

Z. Qin, J. Ai, Q. Du, J. Liu and X. Zeng, Superhydrophobic polytetrafluoroethylene surfaces with accurately and continuously tunable water adhesion fabricated by picosecond laser direct ablation, Mater. Des., 175 (2019) 107782.

Q. Pan, Y. Cao, W. Xue, D. Zhu and W. Liu, Picosecond laser-textured stainless steel superhydrophobic surface with an antibacterial adhesion property, Langmuir, 35 (2019) 11414–11421.

K. Sun et al., Anti-biofouling superhydrophobic surface fabricated by picosecond laser texturing of stainless steel, Appl. Surf. Sci., 436 (2018) 263–267.

I.-H. Cho, J.-H. Lee, J.-W. Noh and S.-W. Lee, A study on surface fabrication of super hydrophobic using pico second laser, J. Korean Soc. Precis. Eng., 29 (2012) 161–169.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Chang-Soo Han

Selvakumar P is a Professor of Mechanical Engineering at PSN College of Engineering and Technology (an autonomous institution affliated with Anna University). He is a recipient of University ranks in both his Bachelor’s and Master’s degrees.

Rights and permissions

About this article

Cite this article

Raja, R.S.S., Selvakumar, P. & Babu, P.D. A novel fabrication of superhydrophobic surfaces on aluminium substrate by picosecond pulsed laser. J Mech Sci Technol 34, 1667–1674 (2020). https://doi.org/10.1007/s12206-020-0329-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-0329-7