Abstract

Polyethylene terephthalate (PET) thermoplastic polyester is durable, formable material that is widely used to manufacture consumer products like sailcloth, sailing spinnakers, food-grade containers, etc. for commercial and engineering applications. The recycling of PET is still a challenge because of its abundance, especially in low-income/developing countries. The present study reports the recycling of PET by utilizing the primary (1°) recycled PET (R-PET) for 3D printing-based sensor applications with the idea of converting waste to wealth. The investigations were performed on PET-based waste collected from institute campus canteens (in form of used food containers/soft drink bottles) after ascertaining their rheological, mechanical, morphological, bonding, and sensing capabilities. The sensing capabilities of R-PET were explored by performing a ring resonator test of a 3D-printed substrate using a vector network analyzer (VNA). The result of the study outlined that R-PET-based sensors may be used in sailcloth, and sailing spinnakers to monitor the location of boats in a shipyard/dock.

Similar content being viewed by others

References

Yang Z J, Harkin-Jones E M A, Armstrong C G and Menary G H 2004 Finite element modeling of stretch-blow molding of PET bottles using Buckley model: Plant tests and effects of process conditions and material parameters. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering 218: 237–250

Craggs G 1990 Mechanics analysis of the die drawing process for producing oriented polyethylene terephthalate (PET) tube. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering 204: 43–50

Małek M, Grzelak K, Łasica W, Jackowski M, Kluczyński J, Szachogłuchowicz I, Torzewski J and Łuszczek J 2022 Cement-glass composite bricks (CGCB) with interior 3D printed PET-G scaffolding. Journal of Building Engineering 28: 104429

Aberoumand M, Soltanmohammadi K, Soleyman E, Rahmatabadi D, Ghasemi I, Baniassadi M, Abrinia K and Baghani M 2022 A comprehensive experimental investigation on 4D printing of PET-G under bending. Journal of Materials Research and Technology 18: 2552–2569

Laville S and Taylor M 2017 A million bottles a minute: world’s plastic binge ‘as dangerous as climate change. The Guardian 28: 2017

Boparai K S, Kumar A and Singh R 2022 Primary and secondary melt processing for plastics. In: Book Additive Manufacturing for Plastic Recycling, pp. 51–64. https://doi.org/10.1201/9781003184164-4

Kumar V, Singh R and Ahuja IPS, Tertiary recycling of plastic solid waste for additive manufacturing. In: Book Additive Manufacturing for Plastic Recycling, pp. 93–109. https://doi.org/10.1201/9781003184164-6

Jiang H, Jiang D, Liu X and Yang J 2021 A self-driven PET chip-based imprinted electrochemical sensor for the fast detection of Salmonella. Sensors and Actuators B: Chemical 349: 130785

Yang W, Weng C, Li X, Xu W, Fei J, Hong J, Zhang J, Zhu W and Zhou X 2022 An “on-off” ratio photoluminescence sensor based on catalytically induced PET effect by Fe3O4 NPs for the determination of coumarin. Food Chemistry 368: 130838

Zhao X, Yan Y, Wen J, Li Y and Li L 2022 Enhancement of magneto-caloric effect in all-d-metal Heusler Mn52.6Ni30.5Co7.8Ti9.1/PVA/PET flexible composite by mechanical strains. Journal of Alloys and Compounds 897: 163116

Özen A, Ganzosch G, Barchiesi E, Auhl D W and Müller W H 2021 Investigation of deformation behavior of PETG-FDM-printed metamaterials with pantographic substructures based on different slicing strategies. Composites and Advanced Materials 30: 1–13

Schneevogt H, Stelzner K, Yilmaz B, Abali B E, Klunker A and Völlmecke C 2021 Sustainability in additive manufacturing: exploring the mechanical potential of recycled PET filaments. Composites and Advanced Materials 30: 1–8

Paesano A, Cohee D and Palmese G R 2003 Carbon-fiber reinforced thermoplastic materials for rigidizable space systems. Journal of Thermoplastic Composite Materials 16: 139–170

Tomaszewski G, Jankowski-Mihułowicz P, Potencki J, Pietrikova A and Lukacs P 2022 Inkjet-printed HF antenna made on PET substrate. Microelectronics Reliability 129: 114473

Liu Q, Yi C, Chen J, Xia M, Lu Y, Wang Y, Liu X, Li M, Liu K and Wang D 2021 Flexible, breathable, and highly environmental-stable Ni/PPy/PET conductive fabrics for efficient electromagnetic interference shielding and wearable textile antennas. Composites Part B: Engineering 215: 108752

Kumar V, Singh R, Ahuja I P and Davim J P 2021 On nano-graphene-reinforced polyvinylidene fluoride composite matrix for 4D applications. Journal of Materials Engineering and Performance 30: 4860–4871

Zeng J J, Zhuge Y, Liang S D, Bai Y L, Liao J and Zhang L 2022 Durability assessment of PEN/PET FRP composites based on accelerated aging in alkaline solution/seawater with different temperatures. Construction and Building Materials 327: 126992

Kumar V, Singh R and Ahuja I P S 2022 On the programming of polyvinylidene fluoride–limestone composite for four-dimensional printing applications in heritage structures. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications 236: 319–33

Griffin J C 1996 Evaluation of pet and recycled pet as replacements for a petg packaging tray. Journal of Plastic Film & Sheeting 12: 139–148

Gileno L A and Turci L F 2021 Life cycle assessment for PET-bottle recycling in Brazil: B2B and B2F routes. Cleaner Environmental Systems 3: 100057

Jiang Z, Yan D, Xin J, Li F, Guo M, Zhou Q, Xu J, Hu Y and Lu X 2022 Poly (ionic liquid) as efficient and recyclable catalysts for methanolysis of PET. Polymer Degradation and Stability 19: 109905

Kumar S, Singh R, Singh AP and Wei Y 2022 Case study for the development of a hybrid composite structure of thermosetting and thermoplastics. In: Book Additive Manufacturing for Plastic Recycling 141-157

Kumar R, Kumar V and Kumar P 2022 Secondary Recycling of HDPE Waste Thermoplastic by Mn Doped ZnO Nanoparticles Reinforcement. In: Encyclopedia of Materials: Plastics and Polymers, pp. 516–523

Kumar V, Singh R and Ahuja I P S 2022 Secondary recycled acrylonitrile–butadiene–styrene and graphene composite for 3D/4D applications: rheological, thermal, magnetometric, and mechanical analyses. Journal of Thermoplastic Composite Materials 35: 761–781

Kangavar M E, Lokuge W, Manalo A, Karunasena W and Frigione M 2022 Investigation on the properties of concrete with recycled polyethylene terephthalate (PET) granules as fine aggregate replacement. Case Studies in Construction Materials 16: e00934

Kumar V, Singh R and Ahuja I P S 2022 On rheological, thermal, mechanical, morphological, and piezoelectric properties and one-way programming features of polyvinylidene fluoride–CaCO3 composites. Journal of Materials Engineering and Performance 1–15

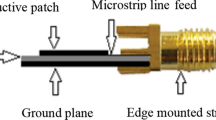

Singh R, Kumar S, Singh A P and Wei Y 2022 On comparison of recycled LDPE and LDPE–bakelite composite based 3D printed patch antenna. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications 236: 842–856

Jain C, Singh R and Dhaliwal B S 2022 On 3D printed ABS based sensors: rheological, mechanical, morphological, rf and 4d capabilities. Journal of Materials Engineering and Performance 1–15

Konieczna M, Markiewicz E and Jurga J 2010 Dielectric properties of polyethylene terephthalate/polyphenylene sulfide/barium titanate nanocomposite for application in electronic industry. Polymer Engineering & Science 50: 1613–1619

Gere D and Czigany T 2020 Future trends of plastic bottle recycling: compatibilization of PET and PLA. Polymer Testing 81: 106160

Sadeghi B, Marfavi Y, AliAkbari R, Kowsari E, Borbor Ajdari F and Ramakrishna S 2021 Recent studies on recycled PET fibers: production and applications: a review. Materials Circular Economy 3: 1–18

Acknowledgements

The research has been partially funded under NTU-PU collaborated project and the Department of Science and Technology, (GoI) provided research facilities under the FIST project (File No. SR/FST/COLLEGE/2020/997).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that no potential conflict of interest in the present study concerning the publication, research, and authorship.

Rights and permissions

About this article

Cite this article

Singh, R., Singh, B.P., Singh, A.P. et al. On 3D printing of low-cost sensors using recycled PET. Sādhanā 47, 260 (2022). https://doi.org/10.1007/s12046-022-02029-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-022-02029-4