Abstract

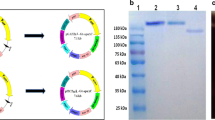

Maltotetraose amylase, which catalyzes the hydrolysis of amylaceous polysaccharides into maltooligosaccharides with maltotetraose as the main product, is extensively used in the food industry. However, the lack of efficient expression system for maltotetraose amylase has hampered its production and application. In this study, high-level production of a maltotetraose amylase mutant (referred to as Pp-Mta∆CBM) from Pseudomonas saccharophila was achieved in Pichia pastoris X-33. First, the gene of maltotetraose amylase with the carbohydrate-binding module (CBM) removed was codon-optimized and cloned into the pPICZαA vector, followed by transformation into P. pastoris X-33 for expression. Using the promoter PAOX1 and signal peptide α-factor, high-level production of Pp-Mta∆CBM with minimal extracellular impurity proteins was achieved, resulting in an extracellular activity of 367.9 U/mL after 7 days of cultivation in shake flasks. Next, the expressed Pp-Mta∆CBM was purified and characterized. This recombinant enzyme was glycosylated and has maximum activity at 55 ℃ and pH 7.0. Its Km for soluble starch was 4.1 g/L, and its kcat was 3237.6 s−1. Finally, the Pp-Mta∆CBM was found to produce a maximum maltotetraose yield of 57.1% in the presence of 200 g/L of substrate. The findings presented in this study demonstrate the efficient production of Pp-Mta∆CBM in P. pastoris, providing a new expression system for maltotetraose amylase and laying the foundation for its scale-up production and industrial application.

Similar content being viewed by others

Data Availability

The data that support the findings of the present study are available from the corresponding author on reasonable request.

References

Kimura, T., & Nakakuki, T. (1990). Maltotetraose, a new saccharide of tertiary property. Starch, 42, 151–157.

Li, J. C., Ban, X. F., Gu, Z. B., Li, C. M., Hong, Y., Cheng, L., & Li, Z. F. (2021). Preparation and antibacterial activity of a novel maltotetraose product. Process Biochemistry, 108, 8–17.

Duan, G., Lee, S. H., Qian, Y., Sala, R. F., & Shetty, J. K. (2012). Production of maltotetraose syrup using a Pseudomonas saccharophila maltotetraohydrolase variant. US20120301927A1.

Duan, K. W., Ban, X. F., Wang, Y. L., Li, C. M., Gu, Z. B., & Li, Z. F. (2022). Improving the product specificity of maltotetraose-forming amylase from Pseudomonas saccharophila STB07 by removing the carbohydrate-binding module. Journal of Agricultural and Food Chemistry, 70, 13709–13718.

Pan, S. H., Ding, N., Ren, J. Y., Gu, Z. B., Li, C. M., Hong, Y., Cheng, L., Holler, T. P., & Li, Z. F. (2017). Maltooligosaccharide-forming amylase: Characteristics, preparation, and application. Biotechnology Advances, 35, 619–632.

Murakami, S., Nagasaki, K., Nishimoto, H., Shigematu, R., Umesaki, J., Takenaka, S., Kaulpiboon, J., Prousoontorn, M., Limpaseni, T., Pongsawasdi, P., & Aoki, K. (2008). Purification and characterization of five alkaline, thermotolerant, and maltotetraose-producing α-amylases from Bacillus halodurans MS-2-5, and production of recombinant enzymes in Escherichia coli. Enzyme and Microbial Technology, 43, 321–328.

Yang, Y. N., Su, L. Q., & Wu, J. (2019). Optimized fermentation condition of recombinant Bacillus subtilis producing maltotetraose amylase and maltotetraose preparation. Food and Fermentation Industries, 45, 44–49.

Fleming, G. T., & Patching, J. W. (1994). Plasmid instability in an industrial strain of Bacillus subtilis grown in chemostat culture. Journal of Industrial Microbiology, 13, 106–111.

Watzlawick, H., & Altenbuchner, J. (2019). Multiple integration of the gene ganA into the Bacillus subtilis chromosome for enhanced β-galactosidase production using the CRISPR/Cas9 system. AMB Express, 9, 158.

Cregg, J. M., Vedvick, T. S., & Raschke, W. C. (1993). Recent advances in the expression of foreign genes in Pichia pastoris. Biotechnology (Nature Publishing Company), 11, 905–910.

Pan, Y. J., Yang, J., Wu, J. P., Yang, L. R., & Fang, H. (2022). Current advances of Pichia pastoris as cell factories for production of recombinant proteins. Frontiers in Microbiology, 13, 1059777.

Liu, W. C., Inwood, S., Gong, T., Sharma, A., Yu, L. Y., & Zhu, P. (2019). Fed-batch high-cell-density fermentation strategies for Pichia pastoris growth and production. Critical Reviews in Biotechnology, 39, 258–271.

Bustos, C., Quezada, J., Veas, R., Altamirano, C., Braun-Galleani, S., Fickers, P., & Berrios, J. (2022). Advances in cell engineering of the Komagataella phaffii platform for recombinant protein production. Metabolites, 12, 346.

Nieto-Taype, M. A., Garrigós-Martínez, J., Sánchez-Farrando, M., Valero, F., Garcia-Ortega, X., & Montesinos-Seguí, J. L. (2020). Rationale-based selection of optimal operating strategies and gene dosage impact on recombinant protein production in Komagataella phaffii (Pichia pastoris). Microbial Biotechnology, 13, 315–327.

Food, U. S., & Administration, D. (2018). Center for food safety and applied nutrition, office of food additive safety. Agency Response Letter GRAS Notice No GRN 000737. https://www.fda.gov/media/116243/download. Accessed Nov 2023.

Food, U. S., & Administration, D. (2006). Center for food safety and applied nutrition, office of food additive safety, Agency Response Letter GRAS Notice No.GRN 000204. https://wayback.archive-it.org/7993/20171031020303/https://www.fda.gov/Food/IngredientsPackagingLabeling/GRAS/NoticeInventory/ucm153734.htm. Accessed Nov 2023.

Wang, Y. L., Li, C. M., Ban, X. F., Gu, Z. B., Hong, Y., Cheng, L., & Li, Z. F. (2022). Disulfide bond engineering for enhancing the thermostability of the maltotetraose-forming amylase from Pseudomonas saccharophila STB07. Foods, 11, 1207.

Yang, F., Zhang, S. F., Jin, G. J., Lin, X. P., & Zhao, Z. K. (2011). Purification and characterization of a β-1,3-glucomannanase expressed in Pichia pastoris. Enzyme and Microbial Technology, 49, 223–228.

Higgins, D. R., & Cregg, J. M. (1998). Pichia protocols. Springer.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31, 426–428.

Cereghino, J. L., & Cregg, J. M. (2000). Heterologous protein expression in the methylotrophic yeast Pichia pastoris. Fems Microbiology Reviews, 24, 45–66.

Lou, Z. H., Liu, X., & Zhang, J. N. (2021). Heterologous expression of maltotetraose-forming amylase from Pseudomnas saccharophila in Bacillus licheniformis. Food and Fermentation Industries, 47, 50–54.

Damasceno, L. M., Huang, C. J., & Batt, C. A. (2012). Protein secretion in Pichia pastoris and advances in protein production. Applied Microbiology and Biotechnology, 93, 31–39.

Deng, B. Y., Yue, Y., Yang, J., Yang, M. J., Xing, Q., Peng, H., Wang, F., Li, M., Ma, L. X., & Zhai, C. (2023). Improving the activity and thermostability of PETase from Ideonella sakaiensis through modulating its post-translational glycan modification. Communications Biology, 6, 39.

Peng, C. C., Hsiao, E. S. L., Ding, J. L. C., & Tzen, J. T. C. (2005). Functional expression in Pichia pastoris of an acidic pectin methylesterase from jelly fig (Ficus awkeotsang). Journal of Agricultural and Food Chemistry, 53, 5612–5616.

Fogarty, W. M., Bourke, A. C., Kelly, C. T., & Doyle, E. M. (1994). A constitutive maltotetraose-producing amylase from Pseudomonas sp. IMD 353. Applied Microbiology and Biotechnology, 42, 198–203.

Zhang, Z. Q. (2019). Secretion expreession of maltotetraose-forming amylase from Pseudomonas saccharophila and analysis of its structure and enzymatic properties. Jiangnan University.

de los Santos, A. I. P., Cayetano-Cruz, M., Gutiérrez-Antón, M., Santiago-Hernández, A., Plascencia-Espinosa, M., Farrés, A., & Hidalgo-Lara, M. E. (2016). Improvement of catalytical properties of two invertases highly tolerant to sucrose after expression in Pichia pastoris. Effect of glycosylation on enzyme properties. Enzyme and Microbial Technology, 83, 48–56.

Yang, M., Yu, X. W., Zheng, H. Y., Sha, C., Zhao, C. F., Qian, M. Q., & Xu, Y. (2015). Role of N-linked glycosylation in the secretion and enzymatic properties of Rhizopus chinensis lipase expressed in Pichia pastoris. Microbial Cell Factories, 14, 40.

Han, M. H., Wang, X. F., Ding, H. Y., Jin, M. Y., Yu, L. G., Wang, J. L., & Yu, X. B. (2014). The role of N-glycosylation sites in the activity, stability, and expression of the recombinant elastase expressed by Pichia pastoris. Enzyme and Microbial Technology, 54, 32–37.

Parashar, D., & Satyanarayana, T. (2017). Production of chimeric acidic α-Amylase by the recombinant Pichia pastoris and its applications. Frontiers in Microbiology, 8, 493.

Carli, S., Meleiro, L. P., & Ward, R. J. (2019). Biochemical and kinetic characterization of the recombinant GH28 Stereum Purpureum endopolygalacturonase and its biotechnological application. International Journal of Biological Macromolecules, 137, 469–474.

Qian, Y., & Duan, G. (2013). Maltotetraose syrup production and process optimization. Journal of Food Science and Biotechnology, 32, 100–104.

Basso, A., & Serban, S. (2019). Industrial applications of immobilized enzymes-A review. Molecular Catalysis, 479, 35–54.

Garcia-Quinto, E., Aranda-Cañada, R., García-García, P., & Fernández-Lorente, G. (2023). Use of potential immobilized enzymes for the modification of liquid foods in the food industry. Processes, 11, 1840.

Kimura, T., Ogata, M., Yoshida, M., & Nakakuki, T. (1988). Continuous production of maltotetraose using immobilized Pseudomonas stutzeri amylase. Biotechnology and Bioengineering, 32, 669–676.

Kimura, T., Ogata, M., Kobayashi, H., Yoshida, M., Oishi, K., & Nakakuki, T. (1990). Continuous production of maltotetraose using a dual immobilized enzyme system of maltotetraose-forming amylase and pullulanase. Biotechnology and Bioengineering, 36, 790–796.

Funding

This research was funded by Scientific Research Fund of Liaoning Provincial Education Department (grant number LJKFZ20220213).

Author information

Authors and Affiliations

Contributions

Investigation, data curation, writing—original draft, Xinyu Wang; investigation, data curation, Ming Xu, Xiaopeng Ren, and Mingyu Li; investigation, data curation, supervision, conceptualization, writing—review and editing, funding acquisition, Conggang Wang; writing—review and editing, Fan Yang and Xianzhen Li. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Ethical Approval

This study does not contain any experiments involving human or animal subjects.

Consent to Participate

Informed consent was obtained from all individual participants included in this study.

Consent for Publication

The authors agreed to publish this paper in Applied Biochemistry and Biotechnology.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Xu, M., Ren, X. et al. High-Level Expression and Biochemical Characterization of a Maltotetraose Amylase in Pichia pastoris X-33 for Maltotetraose Production. Appl Biochem Biotechnol (2024). https://doi.org/10.1007/s12010-024-04871-0

Accepted:

Published:

DOI: https://doi.org/10.1007/s12010-024-04871-0