Abstract

In recent years,4D printing domain is a growing part of additive manufacturing, received a great deal of interest because of its capacity to make products with the ability to alter form and demonstrate behavioural changes when reacts to stimuli from outside. 4D-printed constructions show smart behaviour with transformation as a function of time. In certain cases, the ideal arrangement of a 4D-printed structure cannot be obtained by merely subjecting the smart materials to an external stimulus. As a component of the interaction process, the stimulus being given must be administered in a particular order and over a sufficient quantity of time. Mathematics is required for 4D printing so as to create the material spread and framework required to accomplish the intended shape, property, or utility modification. Theoretical and numerical representations must be established in order to determine the interactions among four fundamental components: the structure of the material, desirable ultimate shape, material characteristics, and stimulus characteristics. This permits self-assembly, multifunction, and self-repair. This paper provides an in-depth examination of the 4D printing procedure, including a summary of the practical concepts, associated tools, processing parameters and future potential of the field.

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Kuang, X., et al.: Advances in 4D printing: materials and applications. Adv. Funct. Mater. 29(2), 1805290 (2019). https://doi.org/10.1002/adfm.201805290

Choi, J., Kwon, O.-C., Jo, W., Lee, H.J., Moon, M.-W.: 4D printing technology: a review. 3D Print Addit. Manuf. 2(4), 159–167 (2015). https://doi.org/10.1089/3dp.2015.0039

Sydney Gladman, A., Matsumoto, E.A., Nuzzo, R.G., Mahadevan, L., Lewis, J.A.: Biomimetic 4D printing. Nat. Mater. 15(4), 413–418 (2016). https://doi.org/10.1038/nmat4544

Khoo, Z.X., et al.: 3D printing of smart materials: a review on recent progresses in 4D printing. Virtual Phys. Prototyp. 10(3), 103–122 (2015). https://doi.org/10.1080/17452759.2015.1097054

Chu, H., et al.: 4D printing: a review on recent progresses. Micromachines 11(9), 796 (2020). https://doi.org/10.3390/mi11090796

Ramezani, M., Mohd Ripin, Z.: 4D printing in biomedical engineering: advancements, challenges, and future directions. J. Funct. Biomater. 14(7), 347 (2023). https://doi.org/10.3390/jfb14070347

Chen, M., Gao, M., Bai, L., Zheng, H., Qi, H.J., Zhou, K.: Recent advances in 4D printing of liquid crystal elastomers. Adv. Mater. 35, 23 (2023). https://doi.org/10.1002/adma.202209566

Rahmatabadi, D., et al.: 4D printing-encapsulated polycaprolactone-thermoplastic polyurethane with high shape memory performances. Adv. Eng. Mater. 25, 6 (2023). https://doi.org/10.1002/adem.202201309

Kumar, A., Kumar, P., Mittal, R.K., Gambhir, V.: Materials processed by additive manufacturing techniques. In: Advances in Additive Manufacturing Artificial Intelligence, Nature-Inspired, and Biomanufacturing, pp. 217–233. Elsevier (2023). https://doi.org/10.1016/B978-0-323-91834-3.00014-4

Kumar, A., Mittal, R.K., Haleem, A. (eds.): Advances in Additive Manufacturing Artificial Intelligence, Nature-Inspired, and Biomanufacturing. Elsevier (2023). https://doi.org/10.1016/C2020-0-03877-6

Lu, H.Z., et al.: Ultrahigh-performance TiNi shape memory alloy by 4D printing. Mater. Sci. Eng. A 763, 138166 (2019). https://doi.org/10.1016/j.msea.2019.138166

Leist, S.K., Zhou, J.: Current status of 4D printing technology and the potential of light-reactive smart materials as 4D printable materials. Virtual Phys. Prototyp. 11(4), 249–262 (2016). https://doi.org/10.1080/17452759.2016.1198630

Lee, A.Y., An, J., Chua, C.K.: Two-way 4D printing: a review on the reversibility of 3D-printed shape memory materials. Engineering 3(5), 663–674 (2017). https://doi.org/10.1016/J.ENG.2017.05.014

Joshi, S., et al.: 4D printing of materials for the future: opportunities and challenges. Appl. Mater. Today 18, 100490 (2020). https://doi.org/10.1016/j.apmt.2019.100490

Behl, M., Ridder, U., Feng, Y., Kelch, S., Lendlein, A.: Shape-memory capability of binary multiblock copolymer blends with hard and switching domains provided by different components. Soft Matter 5(3), 676–684 (2009). https://doi.org/10.1039/B810583A

Zarek, M., et al.: 4D printing shape memory polymers for dynamic jewellery and fashionwear. Virtual Phys. Prototyp. 11(4), 263–270 (2016). https://doi.org/10.1080/17452759.2016.1244085

Soleyman, E., et al.: 4D printing of PET-G via FDM including tailormade excess third shape. Manuf. Lett. 33, 1–4 (2022). https://doi.org/10.1016/j.mfglet.2022.05.002

Ge, Q., Sakhaei, A.H., Lee, H., Dunn, C.K., Fang, N.X., Dunn, M.L.: Multimaterial 4D printing with tailorable shape memory polymers. Sci. Rep. 6(1), 31110 (2016). https://doi.org/10.1038/srep31110

Sun, Y.-C., Wan, Y., Nam, R., Chu, M., Naguib, H.E.: 4D-printed hybrids with localized shape memory behaviour: implementation in a functionally graded structure. Sci. Rep. 9(1), 18754 (2019). https://doi.org/10.1038/s41598-019-55298-1

Großmann, L., Kieckhöfer, M., Weitschies, W., Krause, J.: 4D prints of flexible dosage forms using thermoplastic polyurethane with hybrid shape memory effect. Eur. J. Pharm. Biopharm. 181, 227–238 (2022). https://doi.org/10.1016/j.ejpb.2022.11.009

Liu, Y., et al.: Synergistic effect enhanced shape recovery behavior of metal-4D printed shape memory polymer hybrid composites. Compos. Part B Eng. 179, 107536 (2019). https://doi.org/10.1016/j.compositesb.2019.107536

Adimule, V., Nandi, S.S., Yallur, B.C.: Devices and sensors based on additively manufactured shape-memory of hybrid nanocomposites. In: Shape Memory Composites Based on Polymers and Metals for 4D Printing, pp. 341–359. Springer, Cham (2022). https://doi.org/10.1007/978-3-030-94114-7_15

Liu, G., et al.: 4D additive-subtractive manufacturing of shape memory ceramics. Adv. Mater. (2023). https://doi.org/10.1002/adma.202302108

Farid, M.I., Wu, W., Liu, X., Wang, P.: Additive manufacturing landscape and materials perspective in 4D printing. Int. J. Adv. Manuf. Technol. 115(9–10), 2973–2988 (2021). https://doi.org/10.1007/s00170-021-07233-w

Kang, M., et al.: Design of a shape memory composite (SMC) using 4D printing technology. Sens. Actuat. A Phys. 283, 187–195 (2018). https://doi.org/10.1016/j.sna.2018.08.049

Zhang, H., et al.: 4D printing of Ag nanowire-embedded shape memory composites with stable and controllable electrical responsivity: implications for flexible actuators. ACS Appl. Nano Mater. 5(5), 6221–6231 (2022). https://doi.org/10.1021/acsanm.2c00264

Akbar, I., El Hadrouz, M., El Mansori, M., Lagoudas, D.: Toward enabling manufacturing paradigm of 4D printing of shape memory materials: open literature review. Eur. Polym. J. 168, 111106 (2022). https://doi.org/10.1016/j.eurpolymj.2022.111106

Khalid, M.Y., Arif, Z.U., Noroozi, R., Zolfagharian, A., Bodaghi, M.: 4D printing of shape memory polymer composites: a review on fabrication techniques, applications, and future perspectives. J. Manuf. Process. 81, 759–797 (2022). https://doi.org/10.1016/j.jmapro.2022.07.035

Shiblee, M.N.I., Ahmed, K., Kawakami, M., Furukawa, H.: 4D printing of shape-memory hydrogels for soft-robotic functions. Adv. Mater. Technol. 4(8), 1900071 (2019). https://doi.org/10.1002/admt.201900071

Bharani Kumar, S., Sekar, S.D., Sivakumar, G., Srinivas, J., Lavanya, R., Suresh, G.: Modern concepts and application of soft robotics in 4D printing. J. Phys. Conf. Ser. 2054(1), 012056 (2021). https://doi.org/10.1088/1742-6596/2054/1/012056

Kumar, A., Singh, H., Kumar, P., AlMangour, B.: Handbook of Smart Manufacturing. CRC Press, Boca Raton (2023). https://doi.org/10.1201/9781003333760

Nachimuthu, M.: Inkjet four-dimensional printing of shape memory polymers: a review. Rapid Prototyp. J. 29(3), 437–446 (2023). https://doi.org/10.1108/RPJ-08-2021-0198

Scotton, R.S., Guerrini, L.M., Oliveira, M.P.: Evaluation of solvent-based and UV-curing inkjet inks on the adhesion and printing quality of different aircraft surfaces coating. Prog. Org. Coat. 158, 106389 (2021). https://doi.org/10.1016/j.porgcoat.2021.106389

Mu, Q., Dunn, C.K., Wang, L., Dunn, M.L., Qi, H.J., Wang, T.: Thermal cure effects on electromechanical properties of conductive wires by direct ink write for 4D printing and soft machines. Smart Mater. Struct. 26(4), 045008 (2017). https://doi.org/10.1088/1361-665X/aa5cca

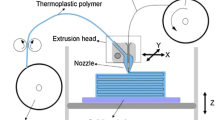

Mocerino, D., Ricciardi, M.R., Antonucci, V., Papa, I.: Fused deposition modelling of polymeric auxetic structures: a review. Polymers (Basel) 15(4), 1008 (2023). https://doi.org/10.3390/polym15041008

Rajan, K., Samykano, M., Kadirgama, K., Harun, W.S.W., Rahman, M.M.: Fused deposition modeling: process, materials, parameters, properties, and applications. Int. J. Adv. Manuf. Technol. 120(3–4), 1531–1570 (2022). https://doi.org/10.1007/s00170-022-08860-7

Vyavahare, S., Kumar, S.: Re-entrant auxetic structures fabricated by fused deposition modeling: an experimental study of influence of process parameters under compressive loading. Polym. Eng. Sci. 60(12), 3183–3196 (2020). https://doi.org/10.1002/pen.25546

Vyavahare, S., Kumar, S.: Numerical and experimental investigation of FDM fabricated re-entrant auxetic structures of ABS and PLA materials under compressive loading. Rapid Prototyp. J. 27(2), 223–244 (2021). https://doi.org/10.1108/RPJ-10-2019-0271

Choong, Y.Y.C., Maleksaeedi, S., Eng, H., Wei, J., Su, P.-C.: 4D printing of high performance shape memory polymer using stereolithography. Mater. Des. 126, 219–225 (2017). https://doi.org/10.1016/j.matdes.2017.04.049

Choong, Y.Y.C., Maleksaeedi, S., Eng, H., Su, P.-C., Wei, J.: Curing characteristics of shape memory polymers in 3D projection and laser stereolithography. Virtual Phys. Prototyp. 12(1), 77–84 (2017). https://doi.org/10.1080/17452759.2016.1254845

Zhao, J., Han, M., Li, L.: Modeling and characterization of shape memory properties and decays for 4D printed parts using stereolithography. Mater. Des. 203, 109617 (2021). https://doi.org/10.1016/j.matdes.2021.109617

Zhao, J., Han, M., Li, L., Tan, M.: Effects of stimulus conditions on shape memory cycle durability of 4D printed parts in stereolithography additive manufacturing. In: Additive Manufacturing; Biomanufacturing; Life Cycle Engineering; Manufacturing Equipment and Automation; Nano/Micro/Meso Manufacturing, vol. 1. American Society of Mechanical Engineers (2022). https://doi.org/10.1115/MSEC2022-85830

Shan, W., Chen, Y., Hu, M., Qin, S., Liu, P.: 4D printing of shape memory polymer via liquid crystal display (LCD) stereolithographic 3D printing. Mater. Res. Express 7(10), 105305 (2020). https://doi.org/10.1088/2053-1591/abbd05

Qu, J., Dou, C., Xu, B., Li, J., Rao, Z., Tsin, A.: Printing quality improvement for laser-induced forward transfer bioprinting: numerical modeling and experimental validation. Phys. Fluids 33, 7 (2021). https://doi.org/10.1063/5.0054675

Kabirian, F., Mela, P., Heying, R.: 4D printing applications in the development of smart cardiovascular implants. Front. Bioeng. Biotechnol. (2022). https://doi.org/10.3389/fbioe.2022.873453

Ashammakhi, N., et al.: Advances and future perspectives in 4D bioprinting. Biotechnol. J. 13(12), 1800148 (2018). https://doi.org/10.1002/biot.201800148

Pourmasoumi, P., et al.: A review on the recent progress, opportunities, and challenges of 4D printing and bioprinting in regenerative medicine. J. Biomater. Sci. Polym. Ed. 34(1), 108–146 (2023). https://doi.org/10.1080/09205063.2022.2110480

Kumari, G., et al.: A voyage from 3D to 4D printing in nanomedicine and healthcare: part II. Nanomedicine 17(4), 255–270 (2022). https://doi.org/10.2217/nnm-2021-0454

Kafle, A., Luis, E., Silwal, R., Pan, H.M., Shrestha, P.L., Bastola, A.K.: 3D/4D printing of polymers: fused deposition modelling (FDM), selective laser sintering (SLS), and stereolithography (SLA). Polymers (Basel) 13(18), 3101 (2021). https://doi.org/10.3390/polym13183101

Mei, S., et al.: 4D printing of polyamide 1212 based shape memory thermoplastic polyamide elastomers by selective laser sintering. J. Manuf. Process. 92, 157–164 (2023). https://doi.org/10.1016/j.jmapro.2023.02.033

Wu, H., et al.: Selective laser sintering-based 4D printing of magnetism-responsive grippers. ACS Appl. Mater. Interfaces 13(11), 12679–12688 (2021). https://doi.org/10.1021/acsami.0c17429

Ouyang, H., Li, X., Lu, X., Xia, H.: Selective laser sintering 4D printing of dynamic cross-linked polyurethane containing diels-alder bonds. ACS Appl. Polym. Mater. 4(5), 4035–4046 (2022). https://doi.org/10.1021/acsapm.2c00565

Naohisa Iwamoto, S.Y., Nagano, T., Sugita, S.: Control system for a dot matrix printer (1990). https://patents.google.com/patent/US5171093

Stangel, I., Zimbeck, W.: Production of dental restorations and other custom objects by free-form fabrication methods and systems therefor (2002). https://patents.google.com/patent/US20030222366A1/en?oq=US20030222366A1

Burce, R.D., Olsen, G.D.: AAA model for fatigue testing (2006). https://patents.google.com/patent/US20070168066A1/en?oq=US20070168066A1

Ionasec, R.I., Sharma, P., Georgescu, B., Torzhkov, A., Moerchen, F., Wittenberg, G.M., Fradkin, D., Comaniciu, D.: Method and system for multi-component heart and aorta modeling for decision support in cardiac disease (2010). https://patents.google.com/patent/US8527251B2/en?oq=US8527251B2

Sjong, A., Brenden, W., Michael, C., Manion, K.: Packaging materials and methods for their preparation and use (2013). https://patents.google.com/patent/WO2015012803A1/en?oq=WO2015012803A1

Tibbits, S.J.E.., Dikovsky, D., Hirsch, S.: Object of additive manufacture with encoded predicted shape change and method of manufacturing same (2014). https://patents.google.com/patent/US20150158244A1/en?oq=US20150158244A1

Feinstein, P.A.: Hybrid smart assembling 4D material (2015). https://patents.google.com/patent/US9427941B2/en?oq=US9427941B2

Lewis, J.A., Gladman, A.S.: Method of 4d printing a hydrogel composite structure (2015). https://patents.google.com/patent/US20170151733A1/en?oq=US20170151733A1

Choong, Y.Y.C., Maleksaeedi, S., Eng, H., Su, P.-C.: Shape memory polymer, formulation for, method of forming and device including the same (2017). https://patents.google.com/patent/WO2017188896A1/en?oq=WO2017188896A1

Zu, S., et al.: 4D printing of core–shell hydrogel capsules for smart controlled drug release. Bio-Des. Manuf. 5(2), 294–304 (2022). https://doi.org/10.1007/s42242-021-00175-y

Javaid, M., Haleem, A.: 4D printing applications in medical field: a brief review. Clin. Epidemiol. Glob. Heal. 7(3), 317–321 (2019). https://doi.org/10.1016/j.cegh.2018.09.007

Wei, H., Zhang, Q., Yao, Y., Liu, L., Liu, Y., Leng, J.: Direct-write fabrication of 4D active shape-changing structures based on a shape memory polymer and its nanocomposite. ACS Appl. Mater. Interfaces 9(1), 876–883 (2017). https://doi.org/10.1021/acsami.6b12824

Chen, X., et al.: Harnessing 4D printing bioscaffolds for advanced orthopedics. Small 18, 36 (2022). https://doi.org/10.1002/smll.202106824

Wang, C., et al.: Advanced reconfigurable scaffolds fabricated by 4D printing for treating critical-size bone defects of irregular shapes. Biofabrication 12(4), 045025 (2020). https://doi.org/10.1088/1758-5090/abab5b

Weng, S., et al.: 4D printing of glass fiber-regulated shape shifting structures with high stiffness. ACS Appl. Mater. Interfaces 13(11), 12797–12804 (2021). https://doi.org/10.1021/acsami.0c18988

Zhang, B., et al.: Photo switchable 4D printing remotely controlled responsive and mechanically robust shape memory polymer nanocomposites. Res. Sq. (2023). https://doi.org/10.21203/rs.3.rs-2867363/v1

Mathilde Champeau, S.T., Heinze, D.A., Viana, T.N., de Souza, E.R., Chinellato, A.C.: 4D printing of hydrogels: a review. Adv. Funct. Mater. Adv. Funct. Mater. 20, 254 (2020)

Huang, L., et al.: Ultrafast digital printing toward 4D shape changing materials. Adv. Mater. 29(7), 1605390 (2017). https://doi.org/10.1002/adma.201605390

Chen, K., et al.: Dynamic photomask-assisted direct ink writing multimaterial for multilevel triboelectric nanogenerator. Adv. Funct. Mater. 29(33), 1903568 (2019). https://doi.org/10.1002/adfm.201903568

Ceamanos, L., Kahveci, Z., López-Valdeolivas, M., Liu, D., Broer, D.J., Sánchez-Somolinos, C.: Four-dimensional printed liquid crystalline elastomer actuators with fast photoinduced mechanical response toward light-driven robotic functions. ACS Appl. Mater. Interfaces 12(39), 44195–44204 (2020). https://doi.org/10.1021/acsami.0c13341

Le Fer, G., Becker, M.L.: 4D printing of resorbable complex shape-memory poly(propylene fumarate) star scaffolds. ACS Appl. Mater. Interfaces 12(20), 22444–22452 (2020). https://doi.org/10.1021/acsami.0c01444

Yuan, J., Lu, X., Liu, Y., Shi, D., Pan, T., Li, Y.: Depressive tendency recognition using the gated recurrent unit from speech and text features. In: 2021 International Conference on Asian Language Processing (IALP), pp. 42–46. IEEE (2021). https://doi.org/10.1109/IALP54817.2021.9675265

Zhang, Y., et al.: 4D printing of a digital shape memory polymer with tunable high performance. ACS Appl. Mater. Interfaces 11(35), 32408–32413 (2019). https://doi.org/10.1021/acsami.9b11062

Sgotti Veiga, J., et al.: Toward fully printed soft actuators: UV-assisted printing of liquid crystal elastomers and biphasic liquid metal conductors. Adv. Mater. Technol. 8, 15 (2023). https://doi.org/10.1002/admt.202300144

Momeni, F., Ni, J.: Laws of 4D printing. Engineering 6(9), 1035–1055 (2020). https://doi.org/10.1016/j.eng.2020.01.015

Naumov, P., Chizhik, S., Panda, M.K., Nath, N.K., Boldyreva, E.: Mechanically responsive molecular crystals. Chem. Rev. 115(22), 12440–12490 (2015). https://doi.org/10.1021/acs.chemrev.5b00398

Wang, G., Tao, Y., Capunaman, O.B., Yang, H., Yao, L.: A-line. In: Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems, pp. 1–12. ACM, New York (2019). https://doi.org/10.1145/3290605.3300656

Liu, F., et al.: Structural evolution of PCL during melt extrusion 3D printing. Macromol. Mater. Eng. 303(2), 1700494 (2018). https://doi.org/10.1002/mame.201700494

Ren, L., et al.: Programming shape-morphing behavior of liquid crystal elastomers via parameter-encoded 4D printing. ACS Appl. Mater. Interfaces 12(13), 15562–15572 (2020). https://doi.org/10.1021/acsami.0c00027

Yuk, H., Zhao, X.: A new 3D printing strategy by harnessing deformation, instability, and fracture of viscoelastic inks. Adv. Mater. 30(6), 1704028 (2018). https://doi.org/10.1002/adma.201704028

Kotikian, A., Truby, R.L., Boley, J.W., White, T.J., Lewis, J.A.: 3D printing of liquid crystal elastomeric actuators with spatially programed nematic order. Adv. Mater. 30(10), 1706164 (2018). https://doi.org/10.1002/adma.201706164

Zhao, Z., Wu, J., Mu, X., Chen, H., Qi, H.J., Fang, D.: Origami by frontal photopolymerization. Sci. Adv. 3, 4 (2017). https://doi.org/10.1126/sciadv.1602326

Lee, S., Bang, D., Park, J.-O., Choi, E.: Programmed shape-morphing material using single-layer 4D printing system. Micromachines 13(2), 243 (2022). https://doi.org/10.3390/mi13020243

van Manen, T., Janbaz, S., Zadpoor, A.A.: Programming 2D/3D shape-shifting with hobbyist 3D printers. Mater. Horizons 4(6), 1064–1069 (2017). https://doi.org/10.1039/C7MH00269F

Shinde, D., Bulsara, M., Mistry, K.N.: Development and investigation of non-asbestos organic friction materials with coconut shell powder as filler. Int. J. Mater. Prod. Technol. 63(3), 228 (2021). https://doi.org/10.1504/IJMPT.2021.117776

Vitale, A., Hennessy, M.G., Matar, O.K., Cabral, J.T.: Interfacial profile and propagation of frontal photopolymerization waves. Macromolecules 48(1), 198–205 (2015). https://doi.org/10.1021/ma5021215

Schiavone, N., Verney, V., Askanian, H.: Effect of 3D printing temperature profile on polymer materials behavior. 3D Print Addit. Manuf. 7(6), 311–325 (2020). https://doi.org/10.1089/3dp.2020.0175

Kumar, A., Kumar, P., Mittal, R.K., Singh, H.: Preprocessing and postprocessing in additive manufacturing. In: Advances in Additive Manufacturing Artificial Intelligence, Nature-Inspired, and Biomanufacturing, pp. 141–165. Elsevier (2023). https://doi.org/10.1016/B978-0-323-91834-3.00005-3

Zhang, C., Lu, X., Fei, G., Wang, Z., Xia, H., Zhao, Y.: 4D printing of a liquid crystal elastomer with a controllable orientation gradient. ACS Appl. Mater. Interfaces 11(47), 44774–44782 (2019). https://doi.org/10.1021/acsami.9b18037

Nishiguchi, A., Zhang, H., Schweizerhof, S., Schulte, M.F., Mourran, A., Möller, M.: 4D printing of a light-driven soft actuator with programmed printing density. ACS Appl. Mater. Interfaces 12(10), 12176–12185 (2020). https://doi.org/10.1021/acsami.0c02781

Chen, D., et al.: 4D printing strain self-sensing and temperature self-sensing integrated sensor-actuator with bioinspired gradient gaps. Adv. Sci. 7(13), 2000584 (2020). https://doi.org/10.1002/advs.202000584

Wang, Y., Li, X.: 4D printing reversible actuator with strain self-sensing function via structural design. Compos. Part B Eng. 211, 108644 (2021). https://doi.org/10.1016/j.compositesb.2021.108644

Teoh, J.E.M., Zhao, Y., An, J., Chua, C.K., Liu, Y.: Multi-stage responsive 4D printed smart structure through varying geometric thickness of shape memory polymer. Smart Mater. Struct. 26(12), 125001 (2017). https://doi.org/10.1088/1361-665X/aa908a

Wang, Z., Wang, Z., Zheng, Y., He, Q., Wang, Y., Cai, S.: Three-dimensional printing of functionally graded liquid crystal elastomer. Sci. Adv. 6, 39 (2020). https://doi.org/10.1126/sciadv.abc0034

Nam, S., Pei, E.: The influence of shape changing behaviors from 4D printing through material extrusion print patterns and infill densities. Materials (Basel) 13(17), 3754 (2020). https://doi.org/10.3390/ma13173754

Yang, Y., Chen, Y., Wei, Y., Li, Y.: 3D printing of shape memory polymer for functional part fabrication. Int. J. Adv. Manuf. Technol. 84(9–12), 2079–2095 (2016). https://doi.org/10.1007/s00170-015-7843-2

Zolfagharian, A., Kaynak, A., Khoo, S.Y., Kouzani, A.: Pattern-driven 4D printing. Sens. Actuat. A Phys. 274, 231–243 (2018). https://doi.org/10.1016/j.sna.2018.03.034

Raviv, D., et al.: Active printed materials for complex self-evolving deformations. Sci. Rep. 4(1), 7422 (2014). https://doi.org/10.1038/srep07422

Atamian, H.S., Creux, N.M., Brown, E.A., Garner, A.G., Blackman, B.K., Harmer, S.L.: Circadian regulation of sunflower heliotropism, floral orientation, and pollinator visits. Science (80-) 353(6299), 587–590 (2016). https://doi.org/10.1126/science.aaf9793

Zolfagharian, A., Kouzani, A.Z., Khoo, S.Y., Noshadi, A., Kaynak, A.: 3D printed soft parallel actuator. Smart Mater. Struct. 27(4), 045019 (2018). https://doi.org/10.1088/1361-665X/aaab29

Deng, D., Yang, Y., Chen, Y., Lan, X., Tice, J.: Accurately controlled sequential self-folding structures by polystyrene film. Smart Mater. Struct. 26(8), 085040 (2017). https://doi.org/10.1088/1361-665X/aa7a4e

Yuan, C., Lu, T., Wang, T.J.: Mechanics-based design strategies for 4D printing: a review. Forces Mech. 7, 100081 (2022). https://doi.org/10.1016/j.finmec.2022.100081

Yuan, C., Wang, F., Ge, Q.: Multimaterial direct 4D printing of high stiffness structures with large bending curvature. Extrem. Mech. Lett. 42, 101122 (2021). https://doi.org/10.1016/j.eml.2020.101122

Yuan, C., Wang, T., Dunn, M.L., Qi, H.J.: 3D printed active origami with complicated folding patterns. Int. J. Precis. Eng. Manuf. Technol. 4(3), 281–289 (2017). https://doi.org/10.1007/s40684-017-0034-x

Peng, B., Yang, Y., Cavicchi, K.A.: Sequential shapeshifting 4D printing: programming the pathway of multi-shape transformation by 3D printing stimuli-responsive polymers. Multifunct. Mater. 3(4), 042002 (2020). https://doi.org/10.1088/2399-7532/abcbe1

Ghazal, A.F., Zhang, M., Liu, Z.: Spontaneous color change of 3D printed healthy food product over time after printing as a novel application for 4D food printing. Food Bioprocess Technol. 12(10), 1627–1645 (2019). https://doi.org/10.1007/s11947-019-02327-6

Stintzing, F.C., Carle, R.: Functional properties of anthocyanins and betalains in plants, food, and in human nutrition. Trends Food Sci. Technol. 15(1), 19–38 (2004). https://doi.org/10.1016/j.tifs.2003.07.004

Chen, C., Zhang, M., Mujumdar, A.S., Phuhongsung, P.: Investigation of 4D printing of lotus root-compound pigment gel: Effect of pH on rapid colour change. Food Res. Int. 148, 110630 (2021). https://doi.org/10.1016/j.foodres.2021.110630

Sehrawat, S., Kumar, A., Prabhakar, M., Nindra, J.: The expanding domains of 3D printing pertaining to the speciality of orthodontics. Mater. Today Proc. 50, 1611–1618 (2022). https://doi.org/10.1016/j.matpr.2021.09.124

Sehrawat, S., et al.: Study of 3D scanning technologies and scanners in orthodontics. Mater. Today Proc. 56, 186–193 (2022). https://doi.org/10.1016/j.matpr.2022.01.064

Shen, C., Chen, W., Li, C., Chen, X., Cui, H., Lin, L.: 4D printing system stimulated by curcumin/whey protein isolate nanoparticles: a comparative study of sensitive color change and post-processing. J. Food Eng. 342, 111357 (2023). https://doi.org/10.1016/j.jfoodeng.2022.111357

Sun, L., et al.: 4D texture: a shape-changing fabrication method for 3D surfaces with texture. In: Extended Abstracts of the 2020 CHI Conference on Human Factors in Computing Systems, pp. 1–7. ACM, New York (2020). https://doi.org/10.1145/3334480.3383053

Feng, C., Zhang, M., Liu, Z., Mujumdar, A., Wang, Y., Chang, L.: Effect of drying method on post-processing stability and quality of 3D printed rose-yam paste. Dry. Technol. 39(9), 1196–1204 (2021). https://doi.org/10.1080/07373937.2020.1851708

Gu, C., et al.: Effects of catalytic infrared drying in combination with hot air drying and freeze drying on the drying characteristics and product quality of chives. LWT 161, 113363 (2022). https://doi.org/10.1016/j.lwt.2022.113363

Nayak, D., Sahu, S.N., Mula, S.: Metallurgical approach towards explaining optimized EDM process parameters for better surface integrity of AISI D2 tool steel. Trans. Indian Inst. Met. 70(5), 1183–1191 (2017). https://doi.org/10.1007/s12666-016-0910-z

Karakurt, I., Lin, L.: 3D printing technologies: techniques, materials, and post-processing. Curr. Opin. Chem. Eng. 28, 134–143 (2020). https://doi.org/10.1016/j.coche.2020.04.001

Milleret, A.: 4D printing of Ni–Mn–Ga magnetic shape memory alloys: a review. Mater. Sci. Technol. 38(10), 593–606 (2022). https://doi.org/10.1080/02670836.2022.2062655

Caputo, M.P., Berkowitz, A.E., Armstrong, A., Müllner, P., Solomon, C.V.: 4D printing of net shape parts made from Ni–Mn–Ga magnetic shape-memory alloys. Addit. Manuf. 21, 579–588 (2018). https://doi.org/10.1016/j.addma.2018.03.028

Aberoumand, M., et al.: A comprehensive experimental investigation on 4D printing of PET-G under bending. J. Mater. Res. Technol. 18, 2552–2569 (2022). https://doi.org/10.1016/j.jmrt.2022.03.121

Melocchi, A., et al.: Retentive device for intravesical drug delivery based on water-induced shape memory response of poly(vinyl alcohol): design concept and 4D printing feasibility. Int. J. Pharm. 559, 299–311 (2019). https://doi.org/10.1016/j.ijpharm.2019.01.045

Vinay Kumar, I.S.A., Singh, R.: Secondary recycled polyvinylidene–limestone composite in 4D printing applications for heritage structures: rheological, thermal, mechanical, spectroscopic, and morphological analysis. Sage J. (2022). https://doi.org/10.1177/0954408922110477

Nayak, D., Sarkar, T., Chaudhary, N.V.P., Bharadwaj, M.D., Ghosh, S., Adyam, V.: Electrochemical properties and first-principle analysisof Na x [M y Mn1−y ]O2 (M = Fe, Ni) cathode. J. Solid State Electrochem. 22(4), 1079–1089 (2018). https://doi.org/10.1007/s10008-017-3850-6

Costanzo, A., et al.: Residual alignment and its effect on weld strength in material-extrusion 3D-printing of polylactic acid. Addit. Manuf. 36, 101415 (2020). https://doi.org/10.1016/j.addma.2020.101415

Andrews, R.D.: Retraction of oriented polystyrene monofilaments. J. Appl. Phys. 26(9), 1061–1067 (1955). https://doi.org/10.1063/1.1722151

Thakkar, R., Pillai, A.R., Zhang, J., Zhang, Y., Kulkarni, V., Maniruzzaman, M.: Novel on-demand 3-dimensional (3-D) printed tablets using fill density as an effective release-controlling tool. Polymers (Basel) 12(9), 1872 (2020). https://doi.org/10.3390/polym12091872

Luzio, A., Criante, L., D’Innocenzo, V., Caironi, M.: Control of charge transport in a semiconducting copolymer by solvent-induced long-range order. Sci. Rep. 3(1), 3425 (2013). https://doi.org/10.1038/srep03425

Nayak, D., et al.: Biphasic α/β-type NaMn 0.89 Fe 0.11 O 2 as a cathode for sodium-ion batteries: structural insight and high-performance relation. ACS Appl. Energy Mater. 5(1), 116–125 (2022). https://doi.org/10.1021/acsaem.1c02576

Nayak, D., Ghosh, S., Adyam, V.: Thin film manganese oxide polymorphs as anode for sodium-ion batteries: an electrochemical and DFT based study. Mater. Chem. Phys. 217, 82–89 (2018). https://doi.org/10.1016/j.matchemphys.2018.06.065

Schwartz, J.J., Boydston, A.J.: Multimaterial actinic spatial control 3D and 4D printing. Nat. Commun. 10(1), 791 (2019). https://doi.org/10.1038/s41467-019-08639-7

Yu, Y., et al.: Material characterization and precise finite element analysis of fiber reinforced thermoplastic composites for 4D printing. Comput. Des. 122, 102817 (2020). https://doi.org/10.1016/j.cad.2020.102817

Hu, W., et al.: Deformation behavior and band gap switching function of 4D printed multi-stable metamaterials. Mater. Des. 200, 109481 (2021). https://doi.org/10.1016/j.matdes.2021.109481

Yazdani Sarvestani, H., Akbarzadeh, A.H., Mirbolghasemi, A., Hermenean, K.: 3D printed meta-sandwich structures: failure mechanism, energy absorption and multi-hit capability. Mater. Des. 160, 179–193 (2018). https://doi.org/10.1016/j.matdes.2018.08.061

Melocchi, A., et al.: Expandable drug delivery system for gastric retention based on shape memory polymers: development via 4D printing and extrusion. Int. J. Pharm. 571, 118700 (2019). https://doi.org/10.1016/j.ijpharm.2019.118700

Fu, P., et al.: 4D printing of polymers: techniques, materials, and prospects. Prog. Polym. Sci. 126, 101506 (2022). https://doi.org/10.1016/j.progpolymsci.2022.101506

Barletta, M., Gisario, A., Mehrpouya, M.: 4D printing of shape memory polylactic acid (PLA) components: Investigating the role of the operational parameters in fused deposition modelling (FDM). J. Manuf. Process. 61, 473–480 (2021). https://doi.org/10.1016/j.jmapro.2020.11.036

Aberoumand, M., Rahmatabadi, D., Aminzadeh, A., Moradi, M.: 4D printing by fused deposition modeling. FDM (2021). https://doi.org/10.1007/978-3-030-68024-4_20

Monzón, M.D., et al.: 4D printing: processability and measurement of recovery force in shape memory polymers. Int. J. Adv. Manuf. Technol. 89(5–8), 1827–1836 (2017). https://doi.org/10.1007/s00170-016-9233-9

Aberoumand, M., et al.: Stress recovery and stress relaxation behaviors of PVC 4D printed by FDM technology for high-performance actuation applications. Sens. Actuat. A Phys. 361, 114572 (2023). https://doi.org/10.1016/j.sna.2023.114572

Yamamura, S., Iwase, E.: Hybrid hinge structure with elastic hinge on self-folding of 4D printing using a fused deposition modeling 3D printer. Mater. Des. 203, 109605 (2021). https://doi.org/10.1016/j.matdes.2021.109605

4D Printing Market (By Material: Programmable Carbon Fiber, Programmable Wood-Custom Printed Wood Grain, Programmable Textile, Programmable Bio Material; By End User: Aerospace and Defense, Automotive, Construction, Clothing, Healthcare, Utility, Others). Precedence Research (2022). https://www.precedenceresearch.com/4d-printing-market#:~:text=Theglobal4Dprintingmarket,morphingsystemoractiveorigami. Accessed 26 Aug 2023

4D Printing Market-Size & Share Analysis-Growth Trends & Forecasts (2023–2028). Mordor Intelligence (2022). https://www.mordorintelligence.com/industry-reports/4d-printing-market. Accessed 26 Aug 2023

Global 4D Printing Market: Type of Programmable Material: Programmable Carbon Fibre, Programmable Textiles, Programmable Biomaterial, Programmable Wood; By End User: Medical, Others; Regional Analysis; Historical Market and Forecast (2018–2028); Market Dy,” Expert Market Research (2022). expertmarketresearch.com/reports/4d-printing-market. Accessed 28 Aug 2023

Acknowledgements

This is a part of academic research work and is under the support of the Department of Metallurgical and Materials Engineering, National Institute of Technology, Rourkela, India.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

All authors are agreed to the publication of the above manuscript. The contribution of all the authors is given below: AM: Writing-original draft preparation, data accumulation, and analysis, AB*: Execution, analysis, Review, and Modification.

Corresponding author

Ethics declarations

Conflict of interest

This manuscript is original, unpublished and not submitted to another journal. There is no conflict of interest in this journal. All authors agreed to submit this research paper. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mishra, A., Behera, A. A critical review on 4D printing and their processing parameters. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01685-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01685-y