Abstract

The multifaceted applications of superhydrophobic surfaces arising out of their unique surface architecture have gained significant attention in the solar photovoltaic industry as it addresses the challenges in light conversion efficiency at an industrial scale due to the soiling of surfaces. Inspired by the self-cleaning properties of the lotus leaf, this review proposes the use of superhydrophobic surfaces as an effective solution for soiling mitigation in solar cell applications. The review examines various factors influencing dust settlement and evaluates existing soiling mitigation techniques. As most literature reports the insufficiency of theoretical wetting models with the controversies around its assumptions, the importance of modified models over the theoretical models is compared and highlighted. The foundations of superhydrophobic coatings including transmittance, porosity, and refractive index of coatings, thickness and surface roughness in addition to the commonly reported surface tension and surface free energy aid to focus on feasible fabrication techniques and provide improved efficiency of solar cells. Finally, the review presents a classification of durability tests to highlight the importance of durable coatings bridging the gap between the fabrication and application of superhydrophobic coatings for solar cells on an industrial scale.

Reproduced with permission from reference (49)

Reproduced with permission from reference (58)

Reproduced with permission from reference (50)

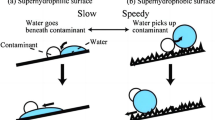

Reproduced with permission from reference (67)

Reproduced with permission from reference (34)

Reproduced with permission from reference (68)

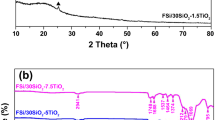

Reproduced with permission from reference (69)

Reproduced with permission from reference (25)

Reproduced with permission from reference (71)

Reproduced with permission from reference (71)

Reproduced with permission from reference (76)

Reproduced with permission from reference (24)

Reproduced with permission from reference (23)

Reproduced with permission from reference (72)

Reproduced with permission from reference (72)

Reproduced with permission from reference (89)

Reproduced with permission from reference (67)

Similar content being viewed by others

References

“Electricity Generation in India.” International Renewable Energy Agency; https://www.irena.org/solar [Accessed on 25 March 2023]

“Global Country Rankings for Solar Electricity Generation.” International Renewable Energy Agency; https://www.irena.org/solar [Accessed on 25 March, 2023].

IEEE Photovoltaic Specialists Conference 40 2014 Denver C, Institute of Electrical and Electronics Engineers, IEEE Electron Devices Society, IEEE Photovoltaic Specialists Conference 40 2014.06.08-13 Denver Colo, PVSC 40 2014.06.08-13 Denver Colo. IEEE 40th Photovoltaic Specialists Conference (PVSC), 2014 Colorado Convention Center, Denver, Colorado, 8-13 June 2014

Schill C, Brachmann S, Heck M, Weiss KA, Koehl M. “Impact of Heavy Soiling on the Power Output of PV Modules.” Reliability of Photovoltaic Cells, Modules, Components, and Systems IV, SPIE; 2011, Vol 8112, p. 811207. https://doi.org/10.1117/12.893721

Hacke P, Terwilliger K, Glick S, et al. “Test-to-Failure of Crystalline Silicon Modules.” Conference Record of the IEEE Photovoltaic Specialists Conference, pp. 244-250, 2010. https://doi.org/10.1109/PVSC.2010.5614472

Rong, J, Fu, J, Zhang, Z, et al. “Development and Evaluation of a Watermelon-Harvesting Robot Prototype: Vision System and End-Effector.” Agronomy, https://doi.org/10.3390/agronomy12112836 (2022)

Wang, P, Xie, J, Ni, L, et al. “Reducing the Effect of Dust Deposition on the Generating Efficiency of Solar PV Modules by Super-Hydrophobic Films.” Sol. Energy, 169 277–283. https://doi.org/10.1016/j.solener.2017.12.052 (2018)

Wang, P, Wang, H, Li, J, Ni, L, Wang, L, Xie, J, “A Superhydrophobic Film of Photovoltaic Modules and Self-cleaning Performance.” Sol. Energy, 226 92–99. https://doi.org/10.1016/j.solener.2021.08.018 (2021)

Parvate S, Dixit P, Chattopadhyay S. Superhydrophobic Surfaces: Insights from Theory and Experiment. 2020.

Huang, ZS, Shen, C, Fan, L, et al. “Experimental Investigation of the Anti-soiling Performances of Different Wettability of Transparent Coatings: Superhydrophilic, Hydrophilic, Hydrophobic and Superhydrophobic Coatings.” Sol. Energy Mater. Sol. Cells, https://doi.org/10.1016/j.solmat.2021.111053 (2021)

Dust Deposition. https://environmenthalfcentury.princeton.edu/research/2021/regular-panel-cleaning-and-air-quality-improvements-increase-solar-output.

Bird Droppings. https://www.solarquotes.com.au/blog/solar-panel-cleaning/.

Manual Cleaning. https://ratedpower.com/blog/soiling-losses/.

Salt Deposition on Solar Panels.https://corrosion.org/Events/Corrosion+Awareness+Day/_/Polina%20VOLOVITCH%20CAD%202020.pdf. Photo: Courtesy of Daniel Lincot.

Robotic Cleaning. https://forum.huawei.com/enterprise/en/solution-of-equipment-maintenance-of-pv-modules/thread/1008155-100027.

Shirtcliffe, NJ, McHale, G, Atherton, S, Newton, MI, “An Introduction to Superhydrophobicity.” Adv. Colloid Interface Sci., 161 (1–2) 124–138. https://doi.org/10.1016/j.cis.2009.11.001 (2010)

Kliuev, M, Wiessner, M, Büttner, H, Maradia, U, Wegener, K, “Super-hydrophobic and Super-hydrophilic Effect by Means of EDM Surface Structuring of γ-TiAl.” Proc. CIRP., 95 393–398. https://doi.org/10.1016/j.procir.2020.02.332 (2020)

Kumikov, VK, Khokonov, KB, “On the Measurement of Surface Free Energy and Surface Tension of Solid Metals.” J. Appl. Phys., 54 (3) 1346–1350. https://doi.org/10.1063/1.332209 (1983)

Orowan, E, “Surface Energy and Surface Tension in Solids and Liquids.” In: Proc. Math Phys. Eng. Sci., Vol. 316, 473–491 (1970). https://doi.org/10.1098/rspa.1970.0091

Ip, SW, Toguri, JM, “The Equivalency of Surface Tension, Energy and Surface Free Energy Surface.” J. Mater. Sci., 29 688–692 (1994)

Li, L, Li, B, Dong, J, Zhang, J, “Roles of Silanes and Silicones in Forming Superhydrophobic and Superoleophobic Materials.” J. Mater. Chem. A, 4 (36) 13677–13725. https://doi.org/10.1039/c6ta05441b (2016)

Liang, Z, Zhou, Z, Zhao, L, Dong, B, Wang, S, “Fabrication of Transparent, Durable and Self-cleaning Superhydrophobic Coatings for Solar Cells.” New J. Chem., 44 (34) 14481–14489. https://doi.org/10.1039/d0nj01402h (2020)

Zheng, J, Yang, J, Cao, W, Huang, Y, Zhou, Z, Huang, YX, “Fabrication of Transparent Wear-Resistant Superhydrophobic SiO2 Film via Phase Separation and Chemical Vapor Deposition Methods.” Ceram. Int., 48 (21) 32143–32151. https://doi.org/10.1016/j.ceramint.2022.07.154 (2022)

Li, W, Tan, X, Zhu, J, et al. “Broadband Antireflective and Superhydrophobic Coatings for Solar Cells.” Mater. Today Energy., 12 348–355. https://doi.org/10.1016/j.mtener.2019.03.006 (2019)

Nosonovsky, M, “Multiscale Roughness and Stability of Superhydrophobic Biomimetic Interfaces.” Langmuir, 23 (6) 3157–3161. https://doi.org/10.1021/la062301d (2007)

Gao, Z, Ma, M, Zhai, X, Zhang, M, Zang, D, Wang, C, “Improvement of Chemical Stability and Durability of Superhydrophobic Wood Surface via a Film of TiO2 Coated CaCO3 Micro-/Nano-composite Particles.” RSC Adv., 5 (79) 63978–63984. https://doi.org/10.1039/c5ra04000k (2015)

Zheng, S, Li, C, Fu, Q, et al. “Fabrication of Self-Cleaning Superhydrophobic Surface on Aluminum Alloys with Excellent Corrosion Resistance.” Surf. Coat. Technol., 276 341–348. https://doi.org/10.1016/j.surfcoat.2015.07.002 (2015)

Latthe, SS, Sudhagar, P, Devadoss, A, et al. “A Mechanically Bendable Superhydrophobic Steel Surface with Its Self-cleaning and Corrosion-resistant Properties.” J. Mater. Chem. A, 3 14263–14271. https://doi.org/10.1039/C5TA02604K (2015)

Zhang, Q, Wang, Y, Wang, Y, Al-Enizi, AM, Elzatahry, AA, Zheng, G, “Myriophyllum-like Hierarchical TiN@Ni3N Nanowire Arrays for Bifunctional Water Splitting Catalysts.” J. Mater. Chem. A, 4 (15) 5713–5718. https://doi.org/10.1039/c6ta00356g (2016)

Org, WE, Mo, C, Zheng, Y, Wang, F, Mo, Q, Electrochemical Science A Simple Process for Fabricating Organic/TiO2 Super-Hydrophobic and Anti-Corrosion Coating. Vol 10, 2015. www.electrochemsci.org

She, X, Wu, J, Xu, H, et al. “Enhancing Charge Density and Steering Charge Unidirectional Flow in 2D Non-Metallic Semiconductor-CNTs-Metal Coupled Photocatalyst for Solar Energy Conversion.” Appl. Catal. B., 202 112–117. https://doi.org/10.1016/j.apcatb.2016.09.013 (2017)

Zhao, L, Liu, Q, Gao, R, Wang, J, Yang, W, Liu, L, “One-step Method for the Fabrication of Superhydrophobic Surface on Magnesium Alloy and Its Corrosion Protection, Antifouling Performance.” Corros. Sci., 80 177–183. https://doi.org/10.1016/j.corsci.2013.11.026 (2014)

Luo, M, Sun, X, Zheng, Y, et al. “Non-fluorinated Superhydrophobic Film with High Transparency for Photovoltaic Glass Covers.” Appl. Surf. Sci.,. https://doi.org/10.1016/j.apsusc.2022.155299 (2023)

Chundi, N, Kesavan, G, Ramasamy, E, Mallick, S, Kottantharayil, A, Sakthivel, S, “Ambient Condition Curable, Highly Weather Stable Anti-Soiling Coating for Photovoltaic Application.” Sol. Energy Mater. Sol. Cells, https://doi.org/10.1016/j.solmat.2021.111203 (2021)

Milionis, A, Loth, E, Bayer, IS, “Recent Advances in the Mechanical Durability of Superhydrophobic Materials.” Adv. Colloid Interface Sci., 229 57–79. https://doi.org/10.1016/j.cis.2015.12.007 (2016)

Rehmer A, Kemnitz E, “Characterization of Nanoscopic Calcium Fluoride Films.” In: Nanostructured Thin Films IX. Vol 9929. SPIE; (2016), 99290F. https://doi.org/10.1117/12.2236842

Wu, Y, Tan, X, Wang, Y, Tao, F, Yu, M, Chen, X, “Nonfluorinated, Transparent, and Antireflective Hydrophobic Coating with Self-cleaning Function.” Colloids Surf. A, https://doi.org/10.1016/j.colsurfa.2021.127919 (2022)

Kim, JH, Choi, YJ, Lee, J, Lee, SG, “Highly Transparent Antireflection Coatings on Fullerene-Free Organic Solar Cells Using Polymeric Nanoparticles.” Thin Solid Films, https://doi.org/10.1016/j.tsf.2021.139043 (2022)

Thin-Film Optical Filters.

Ferrari, M, Cirisano, F, “High Transmittance and Highly Amphiphobic Coatings for Environmental Protection of Solar Panels.” Adv. Colloid Interface Sci., https://doi.org/10.1016/j.cis.2020.102309 (2020)

Guillemot F, Brunet-Bruneau A, Bourgeat-Lami E, Gacoin T, Barthel E, Boilot JP, “Latex-Templated Porous Silica Films for Antireflective Applications.” In: Photonics for Solar Energy Systems III. Vol 7725. SPIE; (2010), 77250G. https://doi.org/10.1117/12.853514

Chen, L, Li, Z, Zhang, P, Tian, P, Yuan, J, Zheng, W, “Effect of PAA on the Structure and Transmittance of Hollow Spherical SiO2 Film Prepared by Sol-Gel Method.” Ceram. Int., 49 (4) 6805–6810. https://doi.org/10.1016/j.ceramint.2022.11.089 (2023)

Zhi, J, Zhang, LZ, “Durable Superhydrophobic Surface with Highly Antireflective and Self-cleaning Properties for the Glass Covers of Solar Cells.” Appl. Surf. Sci., 454 239–248. https://doi.org/10.1016/j.apsusc.2018.05.139 (2018)

Yancey, SE, Zhong, W, Heflin, JR, Ritter, AL, “The Influence of Void Space on Antireflection Coatings of Silica Nanoparticle Self-assembled Films.” J. Appl. Phys.,. https://doi.org/10.1063/1.2171784 (2006)

Nakajima, A, Hashimoto, K, Watanabe, T, Takai, K, Yamauchi, G, Fujishima, A, “Transparent Superhydrophobic Thin Films with Self-Cleaning Properties.” Langmuir., 16 (17) 7044–7047. https://doi.org/10.1021/la000155k (2000)

Zhang, Y, Dong, B, Wang, S, Zhao, L, Wan, L, Wang, E, “Mechanically Robust, Thermally Stable, Highly Transparent Superhydrophobic Coating with Low-Temperature Sol-Gel Process.” RSC Adv., 7 (75) 47357–47365. https://doi.org/10.1039/c7ra08578h (2017)

Hooda, A, Goyat, MS, Pandey, JK, Kumar, A, Gupta, R, “A Review on Fundamentals, Constraints and Fabrication Techniques of Superhydrophobic Coatings.” Prog. Org. Coat., https://doi.org/10.1016/j.porgcoat.2020.105557 (2020)

Sharma, V, Goyat, MS, Hooda, A, et al. “Recent Progress in Nano-oxides and CNTs Based Corrosion Resistant Superhydrophobic Coatings: A Critical Review.” Prog. Org. Coat., https://doi.org/10.1016/j.porgcoat.2019.105512 (2020)

Wang, B, Zhang, Y, Shi, L, Li, J, Guo, Z, “Advances in the Theory of Superhydrophobic Surfaces.” J. Mater. Chem., 22 (38) 20112–20127. https://doi.org/10.1039/c2jm32780e (2012)

Plawsky, JL, Ojha, M, Chatterjee, A, Wayner, PC, “Review of the Effects of Surface Topography, Surface Chemistry, and Fluid Physics on Evaporation at the Contact Line.” Chem. Eng. Commun., 196 (5) 658–696. https://doi.org/10.1080/00986440802569679 (2009)

Brady, VSSR, Ross, AP, Ross, GL, et al. Ind. Eng. Chem. Anal. Ed., 10 (2) 610 (1944)

Gao, L, McCarthy, TJ, “How Wenzel and Cassie Were Wrong.” Langmuir, 23 (7) 3762–3765. https://doi.org/10.1021/la062634a (2007)

McHale, G, “Cassie and Wenzel: Were they Really So Wrong?” Langmuir, 23 (15) 8200–8205. https://doi.org/10.1021/la7011167 (2007)

Costa, MN, Veigas, B, Jacob, JM, et al. “A Low Cost, Safe, Disposable, Rapid and Self-Sustainable Paper-Based Platform for Diagnostic Testing: Lab-on-Paper.” Nanotechnology, https://doi.org/10.1088/0957-4484/25/9/094006 (2014)

Wang, J, Chen, H, Sui, T, Li, A, Chen, D, “Investigation on Hydrophobicity of Lotus Leaf: Experiment and Theory.” Plant Sci., 176 (5) 687–695. https://doi.org/10.1016/j.plantsci.2009.02.013 (2009)

Patankar, NA, “Mimicking the Lotus Effect: Influence of Double Roughness Structures and Slender Pillars.” Langmuir, 20 (19) 8209–8213. https://doi.org/10.1021/la048629t (2004)

Zhang, H, Li, W, Cui, D, Hu, Z, Xu, L, “Design of Lotus-Simulating Surfaces: Thermodynamic Analysis Based on a New Methodology.” Colloids Surf. A, 413 314–327. https://doi.org/10.1016/j.colsurfa.2012.01.036 (2012)

How Long is the Coast of Britain? Statistical self-similarity and fractional dimension.

Zhang, Y, Chen, Y, Shi, L, Li, J, Guo, Z, “Recent Progress of Double-Structural and Functional Materials with Special Wettability.” J. Mater. Chem., 22 (3) 799–815. https://doi.org/10.1039/c1jm14327a (2012)

Chen, X, Weibel, JA, Garimella, SV, “Water and Ethanol Droplet Wetting Transition During Evaporation on Omniphobic Surfaces.” Sci. Rep., https://doi.org/10.1038/srep17110 (2015)

Barman, J, Majumder, SK, Roy, PK, Khare, K, “Tunable Superoleophobicity via Harnessing the Surface Chemistry of UV Responsive Titania Coatings.” RSC Adv., 8 (24) 13253–13258. https://doi.org/10.1039/c8ra01458b (2018)

Grigoryev, A, Tokarev, I, Kornev, KG, Luzinov, I, Minko, S, “Superomniphobic Magnetic Microtextures with Remote Wetting Control.” J. Am. Chem. Soc., 134 (31) 12916–12919. https://doi.org/10.1021/ja305348n (2012)

Tian, X, Jokinen, V, Li, J, Sainio, J, Ras, RHA, “Unusual Dual Superlyophobic Surfaces in Oil-Water Systems: The Design Principles.” Adv. Mater., 28 (48) 10652–10658. https://doi.org/10.1002/adma.201602714 (2016)

Mishra A, Bhatt N, Bajpai AK, “Nanostructured Superhydrophobic Coatings for Solar Panel Applications.” In: Nanomaterials-Based Coatings: Fundamentals and Applications, pp. 397–424. https://doi.org/10.1016/B978-0-12-815884-5.00012-0 (2019)

Raut, HK, Ganesh, VA, Nair, AS, Ramakrishna, S, “Anti-reflective Coatings: A Critical, In-depth Review.” Energy Environ. Sci., 4 (10) 3779–3804. https://doi.org/10.1039/c1ee01297e (2011)

Wang, P, Yan, X, Zeng, J, Luo, C, Wang, C, “Anti-Reflective Superhydrophobic Coatings with Excellent Durable and Self-cleaning Properties for Solar Cells.” Appl. Surf. Sci., https://doi.org/10.1016/j.apsusc.2022.154408 (2022)

Mustafa, HAM, Jameel, DA, “Modeling and the Main Stages of Spin Coating Process: A Review.” J. Appl. Sci. Technol. Trends, 2 (03) 91–95. https://doi.org/10.38094/jastt203109 (2021)

Huovinen, E, Takkunen, L, Korpela, T, Suvanto, M, Pakkanen, TT, Pakkanen, TA, “Mechanically Robust Superhydrophobic Polymer Surfaces Based on Protective Micropillars.” Langmuir, 30 (5) 1435–1443. https://doi.org/10.1021/la404248d (2014)

Routledge, TJ, Lidzey, DG, Buckley, AR, “Ultrasonic Spray Coating as an Approach for Large-area Polymer OLEDs: The Influence of Thin Film Processing and Surface Roughness on Electrical Performance.” AIP Adv.,. https://doi.org/10.1063/1.5082791 (2019)

Manna, S, Naskar, MK, Medda, SK, “Mesoporous Silica-based Abrasion Resistant Antireflective (AR)-cum-Hydrophobic Coatings on Textured Solar Cover Glasses by a Spray Coating Technique.” Mater. Adv., 3 (7) 3208–3217. https://doi.org/10.1039/d1ma01141c (2022)

Salehi, H, Eshaghi, A, Rezazadeh, M, Zabolian, H, “Antireflective and Anti-dust Modified Silica Based Thin Film on Solar Cell Cover Glass.” J. Alloys Compd., https://doi.org/10.1016/j.jallcom.2021.162228 (2022)

Polizos, G, Jang, GG, Smith, DB, et al. “Transparent Superhydrophobic Surfaces Using a Spray Coating Process.” Sol. Energy Mater. Sol. Cells, 176 405–410. https://doi.org/10.1016/j.solmat.2017.10.029 (2018)

Choy, K, Chemical Vapour Deposition of Coatings. www.elsevier.com/locate/pmatsci

Biswas, A, Bayer, IS, Biris, AS, Wang, T, Dervishi, E, Faupel, F, “Advances in Top-down and Bottom-up Surface Nanofabrication: Techniques, Applications & Future Prospects.” Adv. Colloid Interface Sci., 170 (1–2) 2–27. https://doi.org/10.1016/j.cis.2011.11.001 (2012)

Zaytseva, O, Neumann, G, “Carbon Nanomaterials: Production, Impact on Plant Development, Agricultural and Environmental Applications.” Chem. Biol. Technol. Agric., https://doi.org/10.1186/s40538-016-0070-8 (2016)

Zhuang, A, Liao, R, Dixon, SC, et al. “Transparent Superhydrophobic PTFE Films via One-step Aerosol Assisted Chemical Vapor Deposition.” RSC Adv., 7 (47) 29275–29283. https://doi.org/10.1039/c7ra04116k (2017)

Kuhr, M, Bauer, S, Rothhaar, U, Wolff, D, “Coatings on Plastics with the PICVD Technology.” Thin Solid Films, 442 107–116. https://doi.org/10.1016/S0040-6090(03)00956-8 (2003)

Regmi, G, Velumani, S, “Radio Frequency (RF) Sputtered ZrO2-ZnO-TiO2 Coating: An Example of Multifunctional Benefits for Thin Film Solar Cells on the Flexible Substrate.” Solar Energy, 249 301–311. https://doi.org/10.1016/j.solener.2022.11.044 (2023)

Ma, C, Wang, L, Fan, X, Liu, J, “Broadband Antireflection and Hydrophobic CaF2 Film Prepared with Magnetron Sputtering.” Appl. Surf. Sci., https://doi.org/10.1016/j.apsusc.2021.149924 (2021)

Baidya, A, Das, SK, Ras, RHA, Pradeep, T, “Fabrication of a Waterborne Durable Superhydrophobic Material Functioning in Air and Under Oil.” Adv. Mater. Interfaces, https://doi.org/10.1002/admi.201701523 (2018)

Siddiqui, AR, Li, W, Wang, F, Ou, J, Amirfazli, A, “One-step Fabrication of Transparent Superhydrophobic Surface.” Appl. Surf. Sci., https://doi.org/10.1016/j.apsusc.2020.148534 (2021)

Cao, C, Yi, B, Zhang, J, et al. “Sprayable Superhydrophobic Coating with High Processibility and Rapid Damage-Healing Nature.” Chem. Eng. J., https://doi.org/10.1016/j.cej.2020.124834 (2020)

Sutha, S, Suresh, S, Raj, B, Ravi, KR, “Transparent Alumina Based Superhydrophobic Self–cleaning Coatings for Solar Cell Cover Glass Applications.” Sol. Energy Mater. Solar Cells., 165 128–137. https://doi.org/10.1016/j.solmat.2017.02.027 (2017)

Ashraf, M, Champagne, P, Campagne, C, Perwuelz, A, Dumont, F, Leriche, A, “Study the Multi Self-cleaning Characteristics of ZnO Nanorods Functionalized Polyester Fabric.” J. Ind. Text., 45 (6) 1440–1456. https://doi.org/10.1177/1528083714562086 (2016)

Ahmad, AA, Al-Bataineh, QM, Alsaad, AM, Samara, TO, Al-izzy, KA, “Optical Properties of Hydrophobic ZnO Nano-Structure based on Antireflective Coatings of ZnO/TiO2/SiO2 Thin Films.” Physica B Condens. Matter, https://doi.org/10.1016/j.physb.2020.412263 (2020)

Nallathambi, G, Ramachandran, T, Rajendran, V, Palanivelu, R, “Effect of Silica Nanoparticles and BTCA on Physical Properties of Cotton Fabrics.” Mater. Res., 14 (4) 552–559. https://doi.org/10.1590/S1516-14392011005000086 (2011)

Lakshmi, RV, Bera, P, Anandan, C, Basu, BJ, “Effect of the Size of Silica Nanoparticles on Wettability and Surface Chemistry of Sol-Gel Superhydrophobic and Oleophobic Nanocomposite Coatings.” Appl. Surf. Sci., 320 780–786. https://doi.org/10.1016/j.apsusc.2014.09.150 (2014)

Luo, X, Hu, W, Cao, M, Ren, H, Feng, J, Wei, M, “An Environmentally Friendly Approach for the Fabrication of Conductive Superhydrophobic Coatings with Sandwich-like Structures.” Polymers (Basel), https://doi.org/10.3390/polym10040378 (2018)

Isbilir K, Lisco F, Womack G, Abbas A, Walls JM. Testing of an Anti-Soiling Coating for PV Module Cover Glass. (2018)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sathya, R.A., Ponraj, C. Superhydrophobic route of fabricating antireflective, self-cleaning, and durable coatings for solar cell applications. J Coat Technol Res 21, 1–30 (2024). https://doi.org/10.1007/s11998-023-00843-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-023-00843-x