Abstract

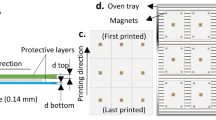

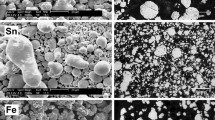

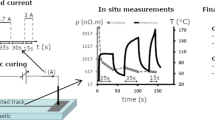

Excess thermal energy can cause significant damage to the mechanical parts of various systems. Temperature sensors can measure and control the temperature in these systems to prevent such damage. However, the applications of existing temperature sensors are limited by their shape as it limits their ability to attach to different surfaces. Consequently, it is challenging to measure the temperature of curved surfaces. In this study, we propose a smart paint that can measure the temperature of curved surfaces to address the above issues. The smart paint fabrication method must be optimized because the resistance characteristics of these paints differ according to the manufacturing conditions. In this study, a curing process was used to manufacture the smart paint; the optimal curing temperature and curing time were determined experimentally. Furthermore, a coating solution was applied to increase the surface stability of the fabricated paint. The coating was applied using a spin coater at a specific rotation time and speed. We also determined the optimal coating conditions. The coating was confirmed to increase the surface stability of the smart paint.

Similar content being viewed by others

References

Tsai, JR, “Overview of Satellite Thermal Analytical Model.” J. Spacecr. Rockets, 41 (1) 120–125 (2004)

Yang, C, Hou, X, Wang, L, “Thermal Design, Analysis and Comparison on Three Concepts of Space Solar Power Satellite.” Acta Astronaut, 137 382–402 (2017)

Zhang, B, Lu, Z, Liu, Z, Liang, G, Chen, Y, “Investigation of a Vehicle Fire Caused by Manufacturing Defect.” Eng. Fail. Anal., 91 28–34 (2018)

Kim, J, Oh, J, Lee, H, “Review on Battery Thermal Management System for Electric Vehicles.” Appl. Therm. Eng., 149 (25) 192–212 (2019)

Elhomdy, E, Liu, Z, Li, G, “Thermal and Mechanical Analysis of a 72/48 Switched Reluctance Motor for Low-speed Direct-drive Mining Applications.” Appl. Sci. Basel, 9 (3) 2722 (2019)

Nitani, M, Nakayama, K, Maeda, K, Omori, M, Uno, M, “Organic Temperature Sensors Based on Conductive Polymers Patterned by a Selective-wetting Method.” Org. Electron., 71 164–168 (2019)

Liu, D, Shi, P, Liu, Y, Zhang, Y, Tian, B, Ren, W, “Optimizing the Properties of La0.8Sr0.2CrO3 Thin Films Through Post-annealing for High-Temperature Sensing.” Nanomaterials, 11 (7) 1802 (2021)

Park, CY, Cho, JH, Kim, YS, Song, HJ, Kim, JD, “Low-cost Temperature Logger for a Polymerase Chain Reaction Thermal Cycler.” Appl. Sci. Basel, 6 (11) 328 (2016)

Jeon, S, Lim, SC, Trung, TQ, Jung, M, Lee, NE, “Flexible Multimodal Sensors for Electric Skin: Principle, Materials, Device, Array Architecture, and Data Acquisition Method.” Proc. IEEE, 107 (10) 2065–2083 (2019)

Hu, YX, Wen, T, Fu, QY, Zhou, DX, Zheng, ZP, Luo, W, Zhao, J, “Preparation and Effects of Glass-coatings on Ba-TiO3-based PTC Thermistors.” J. Mater. Sci.: Mater Electron., 26 7784–78894 (2015)

Yeo, XY, Pecht, MG, “Tab Design and Failures in Cylindrical Li-ion Batteries.” IEEE Access, 7 24082–24095 (2019)

Qu, JJ, Li, S, Liu, F, Yuan, CL, Zhou, DJ, Li, HL, “Effect of Structures and Substrate Temperatures on BaZn0.06Bi0.94O3-δ perovskite-Based NTC Thermistor Thin Films.” Mater. Sci. Semicond. Process., 91 239–245 (2019)

Hao, L, Ding, J, Yuan, N, Xu, J, Zhou, X, Dai, S, Chen, B, “Visual and Flexible Temperature Sensor Based on a Pectin-Xanthan Gum Blend Film.” Org. Electron., 59 243–246 (2018)

Han, DH, Kang, LH, “Piezoelectric Characteristics of PNN-PZT/Epoxy Paint Sensor According to the Poling Conditions.” Sens. Actuator A-Phys., 269 419–426 (2018)

Wang, YR, Zheng, JM, Ren, GY, Xu, C, “A Flexible Piezoelectric Force Sensor Based on PVDF Fabrics.” Smart. Mater. Struct., 20 045009 (2011)

Li, H, Lim, S, “Boosting Performance of Self-polarized Fully Printed Piezoelectric Nanogenerators via Modulated Strength of Hydrogen Bonding Interactions.” Nanomaterials, 11 (8) 1908 (2021)

Kim, SY, Choi, BG, Baek, WK, Park, SH, Park, SW, Shin, JW, Kang, I, “Impact Paint Sensor Based on Polymer/Multi-dimension Carbon Nano Isotopes Composites.” Smart. Mater. Struct., 28 (3) 035025 (2019)

Yang, C, Fritzen, CP, “Piezoelectric Paint: Characterization for Further Applications.” Smart. Mater. Struct., 21 045017 (2012)

Luo, Y, We, D, Zhao, Y, Chen, Q, Xie, Y, Wang, M, Lin, L, Wang, L, Sun, D, “Direct Write of a Flexible High-sensitivity Pressure Sensor with Fast Response for Electronic Skins.” Org. Electron., 67 10–18 (2019)

Klein, C, “Application of Pressure Sensitive Paint (PSP) for the Determination of the Instantaneous Pressure Field of Models in a Wind Tunnel.” Aerosp. Sci. Technol., 4 (2) 103–109 (2000)

Fang, S, Disotell, KJ, Long, SR, Gregory, JW, Semmelmayer, FC, Guyton, RW, “Application of Fast-responding Pressure-sensitive Paint to a Hemispherical Dome in Unsteady Transonic Flow.” Exp. Fluids, 50 1495–1505 (2011)

Huang, CY, Lin, ZC, Wu, MK, “Pressure-Sensitive Paint Measurements for Microscale Supersonic Flow with Wedge Modes.” Aerosp. Sci. Technol., 127 107713 (2022)

Souza, AVS, Valerio, A, Buske, JLO, Benedet, ME, Pistor, V, Machado, RAF, “Influence of Stabilizer Additives on Thermochromic Coating for Temperature Monitoring.” J. Coat. Technol. Res., 13 (6) 1139–1144 (2016)

Fomekong, RL, You, S, Enrichi, F, Vomiero, A, Saruhan, B, “Impact of Oxalate Ligand in Co-precipitation Route on Morphological Properties and Phase Constitution of Undoped and Rh-boped BaTiO3 Nanoparticles.” Nanomaterials, 9 (12) 1697 (2019)

Hagendorf, C, Schindler, KM, Doegem, T, Neddermeyer, H, “Surface Physical Studies of Poly- and Single-crystalline BaTiO3.” Appl. Surf. Sci., 142 106–113 (1999)

Choi, I, Lee, SJ, Kim, JC, Kim, YG, Hyeon, DY, Hong, KS, Suh, J, Shin, D, Jeong, HY, Park, KI, “Piezoelectricity of Picosecond Laser-synthesized Perovskite BaTiO3 Nanoparticles.” Appl. Surf. Sci., 511 145614 (2020)

Chen, L, Jia, Y, Zhao, J, Ma, J, Wu, Z, Yuan, G, Cui, X, “Strong Piezocatalysis in Barium Titanate/Carbon Hybrid Nanocomposites for Dye Wastewater Decomposition.” J. Colloid Interface Sci., 586 758–765 (2021)

Ahn, JH, Leeghim, H, Lee, CY, “Resistance Characteristics and Particle Arrangement of Smart Paint for Surface Temperature Sensor.” J. Nanosci. Nanotechnol., 20 (7) 4263–4266 (2020)

Xie, SH, Zhu, BK, Wei, XZ, Xu, ZK, Xu, YY, “Polyimide/BaTiO3 Composites with Controllable Dielectric Properties.” Compos. Part A Appl. Sci. Manuf., 36 (8) 1152–1157 (2005)

Elbers, NA, Hoeven, JES, Winther, DAM, Schneijdenberg, CTWM, Linden, MN, Filion, L, Blaaderen, A, “Repulsive van der Waals Forces Enable Pickering Emulsions with Non-Touching Colloids.” R. Soc. Chem., 12 7265–7272 (2016)

Fathyunes, L, Azadbeh, A, Tanhaei, M, Sheykholeslami, SOR, “Study on an Elaborated Method to Improve Corrosion Resistance of Zinc Phosphate Coating.” J. Coat. Technol. Res., 14 (3) 709–720 (2017)

Acknowledgments

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2019R1I1A3A01060180). This study was supported by a National Research Foundation of Korea grant funded by the Korean government (MSIT) (2021R1A5A1031868).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahn, JH., Cho, J.Y., Kim, J.H. et al. Optimized curing and coating of smart paints for surface temperature measurements. J Coat Technol Res 20, 1099–1109 (2023). https://doi.org/10.1007/s11998-022-00729-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-022-00729-4