Abstract

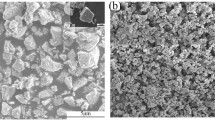

High silica-alumina coated TiO2 pigment with enhanced dry hiding was prepared by the precipitation method under varying treatment conditions. XRF, TEM, FTIR spectra as well as particle size and surface area analyses were used to characterize the prepared TiO2 samples. The pigmentary properties and performance of the TiO2 samples were evaluated. The hiding power of TiO2 particle surface modified with silica throughout in the moderate acidic range has been found to be significantly increased. At moderate acidic pH range, sodium silicate precursor hydrolyzes to form large number of void-bearing siliceous micelles which anchor on the surface of TiO2 pigment to obtain porous coating layers. It is inferred that this voluminous coating containing network of air voids has contributed to the enhanced dry hiding by promoting spatial relationship among the TiO2 particles. This will reduce the amount of TiO2 pigment required without any change in hiding power of low-gloss, flat coatings formulated at high pigment volume concentration. The inventive TiO2 pigment makes a good dry hide grade quality pigment with good optical properties and ink-stain resistance.

Similar content being viewed by others

References

Balfour, JG, “Opacity and titanium dioxide pigments.” J. Oil and Colour Chem. Ass., 245 225–230 (1990)

Bruehlman, RJ, Thomas, LW, Gonick, E, “Effect of particle size and pigment volume concentration on hiding power of titanium dioxide.” Official digest of the federation of societies for paint tech, 252–267 (1961)

Braun, JH, Introduction to Pigments. Blue Bell, Federation Series on Coatings Technology, Federation of Societies for Coatings Technology (1993)

Asbeck, WW, “A critical look at CPVC performance and applications properties.” J. Coat. Tech., 64 47–58 (1992)

Ross, YWD, “Theoretical light-scattering power of TiO2 microvoids.” Ind. Eng. Prod. Res. Develop., 13 45–49 (1974)

Ross, WD, “Theoretical computation of light scattering power: comparison between TiO2 and air bubbles.” J. Paint Tech., 43 50–66 (1971)

Liu, C, Ge, M, Ren, H, “Yin, Effects of coating parameters on the morphology of SiO2-coated TiO2 and the pigmentary properties.” Appl. Sur. Sci., 254 2809–2819 (2008)

Liu, Y, Zhang, Y, Ge, C, Yin, H, Wang, A, Ren, M, Feng, H, Chen, J, Jiang, T, Yu, L, “Evolution mechanism of alumina coating layer on rutile TiO2 powders and the pigmentary properties.” Appl. Sur. Sci., 255 7427–7433 (2009)

Zhang, Y, Yin, H, Wang, A, Ren, M, Gu, Z, Liu, Y, Shen, Y, Yu, L, Jiang, T, “Deposition and characterization of binary Al2O3/SiO2 coating layers on the surface of rutile TiO2 and the pigmentary properties.” Appl. Sur. Sci., 257 1351–1360 (2010)

Zhang, Y, Yin, H, Wang, A, Liu, C, Yu, L, Jiang, T, Hang, Y, “Evolution of zirconia coating layer on rutile TiO2 surface and the pigmentary property.” J. Phy. Chem. Solids, 71 1458–1466 (2010)

Li, J, Liu, Y, Wang, Y, Wang, W, Wang, D, Qi, T, “Hydrous alumina/silica double-layer surface coating of TiO2.” Colloids Surf. A: Physicochem. Eng. Asp., 407 77–84 (2012)

Dong, X, Sun, Z, Jiang, L, Li, C, Zheng, S, “Investigation on the film-coating mechanism of alumina-coated rutile TiO2 and its dispersion stability.” Adv. Powd. Tech., 28 1982–1988 (2017)

Dong, X, Sun, Z, Liu, Y, Jiang, L, Zheng, S, “Insights into effects and mechanism of pre-dispersant on surface morphologies of silica and alumina coated rutile TiO2 particles.” Chem. Phy. Letters, 699 55–63 (2018)

Xu, Q, Zhao, J, Xu, H, Zhou, H, “Dispersion of TiO2 particles and preparation of SiO2 coating layers on the surface of TiO2.” Mat. Res. Innov., 19 142–145 (2015)

Cao, W, Wang, A, Yin, H, “Preparation of TiO2@ZrO2@SiO2@MAA nanocomposites and impact of layer structure on pigmentary performance.” Mat. Chem. Phy. 263 124403 (2021)

Shen, L, Cao, W, Wang, A, Yin, H, “Preparation of TiO2@ZrO2@AlOOH@Polymethyl acrylic acid nanocomposites and impact of layer structure on color scheme, photocatalytic activity, and dispersion stability.” Ind. Eng. Chem. Res., 59 21811–21821 (2020)

Veronovski, N, “TiO2 applications as a function of controlled surface treatment.” In: Chapter 21 Titanium Dioxide–Material for Sustainable Environment, IntechOpen, pp. 421–443. (2018)

Tyler, F, “Tailoring TiO2 treatment chemistry to achieve desired performance properties.” Paint & Layers Ind., 32 16–32 (2000)

Baidins, A, Diebold MP, “High gloss durable TiO2 pigment.” US 5554216 (1996)

Margansky, RE, Ott, MW, “Method of making photodurable aqueous titanium dioxide pigment slurry.” US 5824145 (1998)

Nowacka, M, Ambrohewicz, D, Jesionowski, T, “TiO2-SiO2/Ph-POSS functional hybrids: preparation and characterization.” J. Nanomater., 1–10 (2013)

Brand, JR, Weather resistant titanium dioxide pigment having improved optical properties and process for making same, US 4199370 (1980)

Allen, A, TiO2 pigment coated with dense silica and porous alumina/silica, US 4075031 (1978)

Patton, TC, Paint flow and pigment dispersion : A rheological approach to coating and ink technology, Wiley, New York, pp. 130–157 (1979)

Iler, RK, The chemistry of silica: solubility, polymerization, colloid and surface properties, and biochemistry. Wiley, New York (1979)

Joni, IM, Rukiah, CP, “Synthesis of silica particles by precipitation method of sodium silicate: Effect of temperature, pH and mixing technique.” In 2nd International Conference and Exhibition on Powder Technology (ICePTi) (2019), AIP Publishing.

van Santen, RA, Beelen, TPM, van Garderen, HF, Dokter, WH, Pantos, E, “Aggregation and aging in silica gel.” Nucl. Instr. Meth. Phys. Res. B, 97 231–237 (1995)

Wilhelm, S, Kind, SM, “On the relation between natural and enforced syneresis of acidic precipitated silica.” Polymers, 6 2896–2911 (2014)

Katoueizadeh, E, Rasouli, M, Zeberjad, SM, “A comprehensive study on the gelation process of silica gels from sodium silicate.” J. Mat. Res. Tech., 9 10157–10165 (2020)

Eneng, M, Rifki, S, “Suhanda, Effects of the precipitation pH of sodium silicate on the amorphous silica characteristics and its capability in the Pb and Cd Adsorption.” Res. J. Chem. Environ., 22 172–178 (2018)

Brinker, CJ, Scherer, GW, Sol-gel science-The physics and chemistry of sol-gel processing. Academic Press Inc., San Diego (1990)

Hamouda, AA, Hossien, A, Amiri, A, “Factors affecting alkaline sodium silicate gelation for in-depth reservoir profile modification.” Energies, 7 568–590 (2014)

Zerda, TW, Artaki, I, Jonas, J, “Study of polymerization processes in acid and base catalyzed silica sol-gels.” J. Non-Cryst. Solids, 81 365–379 (1986)

Wilhelm, S, Kind, M, “Influence of pH, temperature and sample size on natural and enforced syneresis of precipitated silica.” Polymers, 7 2504–2521 (2015)

Acknowledgments

The authors gratefully acknowledge the Managing Director of ‘The Kerala Minerals and Metals Limited,’ Kerala, India for providing the opportunity to perform the study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

George, J., Manikuttan, P.K. & Shaju, I.K. High silica-alumina-coated TiO2 pigment with improved dry hiding for flat paints. J Coat Technol Res 19, 1665–1672 (2022). https://doi.org/10.1007/s11998-022-00638-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-022-00638-6