Abstract

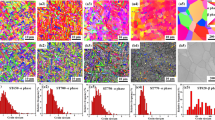

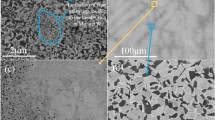

Metastable β titanium alloy with bi-modal structure usually exhibits excellent Strength–ductility combination. However, the origin of this improved mechanical properties on the dislocation level has not been thoroughly investigated. An improved Strength–ductility combination is exhibited in a metastable β titanium alloy Ti-5Al-4Zr-8Mo-7V with bi-modal structure. High ultimate tensile strength (UTS) ~ 1390 MPa with considerable elongation ~ 10.2% is acquired. A novel core-shell structure in primary α was found for the first time to our knowledge during tensile deformation. High density of geometrically necessary dislocations consisting of pyramidal a + c type and a type dislocation is displayed in the hard-shell layer, while low density of statistically stored dislocations consisting of a type dislocation is exhibited in the core area. The improved ductility originates from this core-shell structure. The hard shell improves the plastic compatibility between soft primary α and hard transformed β matrix, which alleviates stress concentration and postpones crack nucleation along primary α phase (αp)/β matrix interface. Meanwhile, the soft core sustains uniform deformation effectively, which ensures the ductility. In addition, the origin of high strength is attributed to fine-scale α platelets (αs) with highly defected substructure.

Similar content being viewed by others

References

D. Banerjee and J.C. Williams, Acta Mater. 61, 844 https://doi.org/10.1016/j.actamat.2012.10.043 (2013).

G.T. Terlinde, T.W. Duerig, and J.C. Williams, Metall. Trans. A 14, 2101 https://doi.org/10.1007/BF02662377 (1983).

S. Hémery and P. Villechaise, MSEA 697, 177 https://doi.org/10.1016/j.msea.2017.05.021 (2017).

G. Srinivasu, Y. Natraj, A. Bhattacharjee, T.K. Nandy, and G.V.S. Nageswara Rao, Mater. Des. 47, 323 https://doi.org/10.1016/j.matdes.2012.11.053 (2013).

J.K. Fan, J.S. Li, H.C. Kou, K. Hua, and B. Tang, Mater. Charact. 96, 93 https://doi.org/10.1016/j.matchar.2014.07.018 (2014).

S. Shekhar, R. Sarkar, S.K. Kar, and A. Bhattacharjee, Mater. Des. 66, 596 https://doi.org/10.1016/j.matdes.2014.04.015 (2015).

W. Zhu, Q. Sun, C. Tan, P. Li, L. Xiao, and J. Sun, J. Alloy Compd. https://doi.org/10.1016/j.jallcom.2020.154311 (2020).

D. Qin, Y. Li, S. Zhang, and L. Zhou, J. Alloy Compd. 663, 581 https://doi.org/10.1016/j.jallcom.2015.12.158 (2016).

S.A. Mantri, D. Choudhuri, T. Alam, G.B. Viswanathan, J.M. Sosa, H.L. Fraser, and R. Banerjee, Scripta Mater. 154, 139 https://doi.org/10.1016/j.scriptamat.2018.05.040 (2018).

A. Settefrati, M. Dehmas, G. Geandier, B. Denand, E. Aeby-Gautier, B. Appolaire, G. Khelifati and J. Delfosse, In World Conference Titanium, (2011).

E. Aeby-Gautier, A. Settefrati, F. Bruneseaux, B. Appolaire, B. Denand, M. Dehmas, G. Geandier, and P. Boulet, J. Alloy Compd. 577, S439 https://doi.org/10.1016/j.jallcom.2012.02.046 (2013).

A. Settefrati, E. Aeby-Gautier, B. Appolaire, M. Dehmas, G. Geandier, and G. Khelifati, Mater. Sci. Forum. 738, 97–102 (2013).

W. Zhu, J. Lei, B. Su, and Q. Sun, MSEA 782, 139248 https://doi.org/10.1016/j.msea.2020.139248 (2020).

L.C. Campanelli, P.S.C.P. da Silva, and C. Bolfarini, MSEA 658, 203 https://doi.org/10.1016/j.msea.2016.02.004 (2016).

L. Ren, W. Xiao, H. Chang, Y. Zhao, C. Ma, and L. Zhou, MSEA 711, 553 https://doi.org/10.1016/j.msea.2017.11.029 (2018).

W. Zhu, J. Lei, Z. Zhang, Q. Sun, W. Chen, L. Xiao, and J. Sun, MSEA 762, 138086 https://doi.org/10.1016/j.msea.2019.138086 (2019).

R.K. Nalla, R.O. Ritchie, B.L. Boyce, J.P. Campbell, and J.O. Peters, Metall. Mater. Trans. A 33, 899 https://doi.org/10.1007/s11661-002-0160-z (2002).

S. Sadeghpour, S.M. Abbasi, M. Morakabati, and S. Bruschi, Mater Des. 121, 24 https://doi.org/10.1016/j.matdes.2017.02.043 (2017).

J.O. Peters, G. Lütjering, M. Koren, H. Puschnik, and R.R. Boyer, MSEA 213, 71 https://doi.org/10.1016/0921-5093(96)10225-2 (1996).

Z. Du, S. Xiao, L. Xu, J. Tian, F. Kong, and Y. Chen, Mater. Des. 55, 183 (2014).

S.K. Kar, S. Suman, S. Shivaprasad, A. Chaudhuri, and A. Bhattacharjee, MSEA 610, 171 https://doi.org/10.1016/j.msea.2014.04.113 (2014).

J. Fan, J. Li, H. Kou, K. Hua, B. Tang, and Y. Zhang, J. Alloy Compd. 682, 517 https://doi.org/10.1016/j.jallcom.2016.04.303 (2016).

D. Lunt, X. Xu, T. Busolo, J. Quinta da Fonseca, and M. Preuss, Scripta Mater. 145, 45 https://doi.org/10.1016/j.scriptamat.2017.10.012 (2018).

S. Zhang, W. Zeng, Q. Zhao, L. Ge, and M. Zhang, MSEA 708, 574 https://doi.org/10.1016/j.msea.2017.10.028 (2017).

P. Castany, F. Pettinari-Sturmel, J. Crestou, J. Douin, and A. Coujou, Acta Mater. 55, 6284 https://doi.org/10.1016/j.actamat.2007.07.032 (2007).

C. Tan, Q. Sun, L. Xiao, Y. Zhao, and J. Sun, MSEA 725, 33 https://doi.org/10.1016/j.msea.2018.03.123 (2018).

P. Castany, F. Pettinari-Sturmel, J. Douin, and A. Coujou, MSEA 680, 85 https://doi.org/10.1016/j.msea.2016.10.020 (2017).

G.B. Viswanathan, E. Lee, D.M. Maher, S. Banerjee, and H.L. Fraser, Acta Mater. 53, 5101 https://doi.org/10.1016/j.actamat.2005.07.030 (2005).

S.L. Raghunathan, A.M. Stapleton, R.J. Dashwood, M. Jackson, and D. Dye, Acta Mater. 55, 6861 https://doi.org/10.1016/j.actamat.2007.08.049 (2007).

O.M. Ivasishin, P.E. Markovsky, Y.V. Matviychuk, S.L. Semiatin, C.H. Ward, and S. Fox, J. Alloy Compd. 457, 296 https://doi.org/10.1016/j.jallcom.2007.03.070 (2008).

B. He, J. Li, X. Cheng, and H.-M. Wang, MSEA 699, 229 https://doi.org/10.1016/j.msea.2017.05.050 (2017).

W. Zhu, C. Tan, R. Xiao, Q. Sun, and J. Sun, J. Mater. Sci. Technol. https://doi.org/10.1016/j.jmst.2020.03.053 (2020).

Y. Chen, Z. Du, S. Xiao, L. Xu, and J. Tian, J. Alloy Compd. 586, 588 https://doi.org/10.1016/j.jallcom.2013.10.096 (2014).

W.-G. Zhu, P. Li, X. Sun, W. Chen, H.-L. Zhang, Q.-Y. Sun, B. Liu, L. Xiao, and J. Sun, TNMSC 29, 1242 https://doi.org/10.1016/S1003-6326(19)65031-4 (2019).

K. Hua, Y. Zhang, H. Kou, J. Li, W. Gan, J.-J. Fundenberger, and C. Esling, Acta Mater. 132, 307 https://doi.org/10.1016/j.actamat.2017.04.051 (2017).

D. Qin, Y. Lu, D. Guo, L. Zheng, Q. Liu, and L. Zhou, MSEA 587, 100 https://doi.org/10.1016/j.msea.2013.08.055 (2013).

J. Huang, Z. Wang, and J. Zhou, Metall. Mater. Trans. A 42, 2868 https://doi.org/10.1007/s11661-011-0705-0 (2011).

J. Huang, Z. Wang, and K. Xue, MSEA 528, 8723 https://doi.org/10.1016/j.msea.2011.08.045 (2011).

L. Lan, M. Yu, and C. Qiu, MSEA 742, 442 https://doi.org/10.1016/j.msea.2018.11.011 (2019).

N. Kamikawa, K. Sato, G. Miyamoto, M. Murayama, N. Sekido, K. Tsuzaki, and T. Furuhara, Acta Mater. 83, 383 https://doi.org/10.1016/j.actamat.2014.10.010 (2015).

C. Herrera, D. Ponge, and D. Raabe, Acta Mater. 59, 4653 https://doi.org/10.1016/j.actamat.2011.04.011 (2011).

J. Kadkhodapour, S. Schmauder, D. Raabe, S. Ziaei-Rad, U. Weber, and M. Calcagnotto, Acta Mater. 59, 4387 https://doi.org/10.1016/j.actamat.2011.03.062 (2011).

M.F. Ashby, Philos. Mag. 21, 399 https://doi.org/10.1080/14786437008238426 (1970).

H. Ghassemi-Armaki, R. Maaß, S.P. Bhat, S. Sriram, J.R. Greer, and K.S. Kumar, Acta Mater. 62, 197 https://doi.org/10.1016/j.actamat.2013.10.001 (2014).

Acknowledgements

The authors thank Engineer Fang Song at Instrumental Analysis Center, Xi’an University of Architecture and Technology, for her help with SEM/EBSD characterization. We appreciate the support from BAOTI Group Co., Ltd., for material preparation and processing. This work was supported by the National Natural Science Foundation of China (grant nos. 52275161, 52201134) and International Science and Technology Cooperation Projects of Shaanxi Province, China (grant no. 2021KW27).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, W., Zhang, P., He, Y. et al. Microstructural Analysis of the Improved Strength–Ductility Combination in Titanium Alloy with Bi-modal Structure. JOM 76, 1659–1668 (2024). https://doi.org/10.1007/s11837-023-06013-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06013-z