Abstract

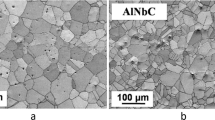

In recent years, lightweight steels have become a hot research topic in the field of materials. However, little research has been done on the corrosion resistance, which is of great significance to the service life of the alloy. In this paper, the initial corrosion behaviour of Fe-Mn-Al-C-Ni lightweight steels with different B2-phase grain sizes in 3.5 wt.% NaCl solution was investigated. The immersion corrosion process of Fe-Mn-Al-C-Ni mild steel and the selective corrosion characteristics of the alloy surface were revealed by quasi-in-situ short-period immersion tests and electrochemical experiments. As a result, the grain size of the granular B2 phase is significantly reduced compared with that of the striped B2 phase, and the granular B2 phase is diffusely distributed in the matrix, which makes the corrosion tend to be uniform and improves the corrosion resistance of the alloy.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Y. Sutou, N. Kamiya, R. Umino, I. Ohnuma, and K. Ishida, ISIJ Inter. https://doi.org/10.2355/isijinternational.50.893 (2010).

R. Rana, JOM. https://doi.org/10.1007/s11837-014-1137-2 (2014).

H. Kim, D.W. Suh, and N.J. Kim, Sci. Technol. Adv. Mater. https://doi.org/10.1088/1468-6996/14/1/014205 (2013).

O.A. Zambrano, J. Mater. Sci. https://doi.org/10.1007/s10853-018-2551-6 (2018).

L. Wang, C.F. Dong, C. Man, Y.B. Hu, Q. Yu, and X.G. Li, Int. J. Min. Met. Mater. https://doi.org/10.1007/s12613-020-2242-6 (2021).

P.J. Wang, L.W. Ma, X.Q. Cheng, and X.G. Li, Int. J. Miner. Metall. Mater. https://doi.org/10.1007/s12613-021-2308-0 (2021).

I. Ohnuma, N. Kamiya, Y. Suto, T. Omori, R. Kainuma and K. Ishida, (2010) Thermodynamic database high-strenght low-density steels. Paper presented at the Discussion Meeting on Thermodynamics of Alloys 2010, Tohoku University, Sendai, Porto, 12–16 September 2010

D. Raabe, H. Springer, I.G. Urrutia, F. Roters, M. Bausch, J.B. Seol, M. Koyama, P.P. Choi, and K. Tsuzaki, TMS. https://doi.org/10.1007/s11837-014-1032-x (2014).

M.S. Kim, and Y.B. Kang, Calphad. https://doi.org/10.1016/j.calphad.2015.08.004 (2015).

P. Maugis, J. Lacaze, R. Besson, and J. Morillo, Metall. Mater. Trans. https://doi.org/10.1007/s11661-006-1032-8 (2006).

W.C. Cheng, Metall. Mater. Trans. A. https://doi.org/10.1007/s11661-005-0038-y (2005).

Y.T. Ma, Y. Li, and F.H. Wang, Mater. Chem. Phys. https://doi.org/10.1016/j.matchemphys.2008.06.066 (2008).

H.H. Huang, and T.H. Chuang, Mater. Sci. Eng. A. https://doi.org/10.1016/S0921-5093(00)01021-2 (2000).

K.Y. Choi, C.H. Seo, H. Lee, S.K. Kim, J.H. Kwak, K.G. Chin, K.T. Park, and N.J. Kim, Scr. Mater. https://doi.org/10.1016/j.scriptamat.2010.07.036 (2010).

F.Q. Yang, R.B. Song, Y.P. Li, T. Sun, and K.K. Wang, Mater. Des. https://doi.org/10.1016/j.matdes.2015.03.043 (2015).

S.H. Kim, H. Kim, and N.J. Kim, Nature. https://doi.org/10.1038/nature14144 (2015).

A. Rahnama, H. Kotadia, S. Clark, V. Janik, and S. Sridhar, Sci. Rep. https://doi.org/10.1038/s41598-018-27345-w (2018).

A. Rahnamal, H. Kotadia, and S. Sridhar, Acta Mater. https://doi.org/10.1016/j.actamat.2017.03.043 (2017).

R.J. Thibeau, C.W. Brown, and R.H. Heidersbach, Appl. Spectrosc. https://doi.org/10.1366/000370278774330739 (1978).

G. Park, C.H. Nam, A. Zargaran, and N.J. Kim, Scr. Mater. https://doi.org/10.1016/j.scriptamat.2019.02.013 (2019).

A. Misra, H.D. Bist, M.S. Navati, R.K. Thareja, and J. Narayan, Mater. Sci. Eng. B. https://doi.org/10.1016/S0921-5107(00)00554-7 (2001).

A.C. Agudelo, J.F. Marco, J.R. Gancedo, and G.A. Pérez-Alcázar, Inter. Hyper. https://doi.org/10.1023/A:1021248519209 (2002).

J.H. Hwang, T.T.T. Trang, O. Lee, G. Park, A. Zargaran, and N.J. Kim, Acta Mater. https://doi.org/10.1016/j.actamat.2020.03.022 (2020).

H. Kim, Scr. Mater. https://doi.org/10.1016/j.scriptamat.2018.09.044 (2019).

S.F. Zhu, Y.P. Wu, T.W. Liu, K. Tang, Q. Wei, and A.C.S. App, Mater. Inter. https://doi.org/10.1021/am401284e (2013).

Y.S. Zhang, and X.M. Zhu, Corros. Sci. https://doi.org/10.1016/S0010-938X(99)00017-7 (1999).

Y.S. Zhang, X.M. Zhu, and S.H. Zhong, Corros. Sci. https://doi.org/10.1016/j.corsci.2003.09.002 (2004).

S. Fajardoa, I. Llorentea, J.A. Jiméneza, J.M. Bastidasa, and D.M. Bastidas, Corros. Sci. https://doi.org/10.1016/j.corsci.2019.04.026 (2019).

S.C. Tjong, Surf. Coat. Techno. https://doi.org/10.1016/0257-8972(86)90056-3 (1986).

T. Dieudonné, L. Marchetti, M. Wery, F. Miserque, M. Tabarant, J. Chêne, C. Allely, P. Cugy, and C.P. Scott, Corros. Sci. https://doi.org/10.1016/j.corsci.2014.02.018 (2014).

J. Liu, W.P. Chen, X.M. Zhang, and Z.Q. Fu, J. Iron Steel Res. https://doi.org/10.1007/s42243-018-0080-9 (2018).

S. Barella, A.F. Ciuffini, A. Gruttadauria, C. Mapelli, D. Mombelli, and E. Longaretti, Mater. https://doi.org/10.3390/ma12162572 (2019).

M. Cavallini, F. Felli, R. Fratesi, and F. Veniali, Mater. Corros. https://doi.org/10.1002/maco.19820330506 (1982).

T. Ohtsuka, K. Kubo, and N. Sato, Corrosion. https://doi.org/10.5006/1.3583054 (1986).

E.J. Akiyama, S.J. Li, T. Shinohara, Z.G. Zhang, and K. Tsuzaki, Electrochem. Acta. https://doi.org/10.1016/j.electacta.2010.09.043 (2011).

X.X. Xu, H.L. Cheng, W. Wu, Z.Y. Liu, and X.G. Li, Corros. Sci. https://doi.org/10.1016/j.corsci.2021.109760 (2021).

W. Peng, Z.Y. Wu, Y.L. Xu, Q.X. Ran, W.J. Xu, J. Li, and X.S. Xiao, Corros. Sci. https://doi.org/10.1016/j.corsci.2017.03.005 (2017).

W. Wu, L. Qin, X. Cheng, F. Xu, and X. Li, Corros. Sci. https://doi.org/10.1016/j.corsci.2022.110936 (2023).

M.X. Yang, F.P. Yuan, Q.G. Xie, Y.D. Wang, E. Ma, and X.L. Wu, Acta Mater. https://doi.org/10.1016/j.actamat.2016.02.044 (2016).

X.J. Yang, Y. Yang, M.H. Sun, J.H. Jia, X.Q. Cheng, Z.B. Pei, Q. Li, D. Xu, K. Xiao, X.G. Li, and J. Mater, Sci. Technol. https://doi.org/10.1016/j.jmst.2021.05.086 (2021).

B. Hirschorn, M.E. Orazem, B. Tribollet, V. Vivier, I. Frateur, and M. Musiani, J. Electrochem. Soc. https://doi.org/10.1149/1.3499565 (2010).

Z.Y. Cui, L.W. Wang, H.T. Ni, W.K. Haoc, C. Man, S.S. Chena, X. Wang, Z.Y. Liu, and X.G. Li, Corros. Sci. https://doi.org/10.1016/j.corsci.2017.01.016 (2017).

A. Collazo, X.R. Novoa, C. Perez, and B. Puga, Electrochem. Acta. https://doi.org/10.1016/j.electacta.2007.11.078 (2008).

J.H. Jia, X.Q. Cheng, X.J. Yang, X.G. Li, and W. Li, Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2020.119760 (2020).

X.Y. Liu, Inorganic Chemistry, (Xiayun Liu, Chengdu, 2018), pp. 255–256

B.Z. Sun, X.M. Zuo, X.Q. Cheng, X.G. Li, and N.P.J. Mater, Degrad. https://doi.org/10.1038/s41529-020-00142-5 (2020).

P. Liu, L.L. Hua, X.Y. Zhao, Q.H. Zhang, Z.S. Yu, J.M. Hua, Y.Q. Chen, F.F. Wu, and F.H. Cao, Corros. Sci. https://doi.org/10.1016/j.corsci.2020.108686 (2020).

Y. Yang, X.Q. Cheng, J.B. Zhao, Y. Fan, and X.G. Li, Corros. Sci. https://doi.org/10.1016/j.corsci.2021.109549 (2021).

Acknowledgements

The authors are grateful for the financial support of the National Natural Science Foundation of China (no. 52171063) and the China Postdoctoral Science Foundation (no. 2022M710348).

Funding

Innovative Research Group Project of the National Natural Science Foundation of China, 52171063, Xuequn Cheng, Postdoctoral Research Foundation of China, 2022M710348, Xuequn Cheng.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qin, L., Wu, W., Cheng, X. et al. Study of the Mechanism Influencing the Initial Corrosion Behaviour of B2 Phase Fe-Mn-Al-C-Ni Lightweight Steels in 3.5% NaCl Solution. JOM 75, 2212–2224 (2023). https://doi.org/10.1007/s11837-023-05753-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05753-2