Abstract

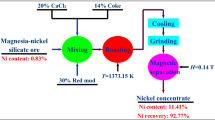

In this study, a magnetic separation–shaking table gravity separation process was used to treat Sc-bearing V–Ti magnetite tailings, and the Sc2O3 content in the Sc concentrate was enhanced from 0.0039 to 0.0061%. The majority of the Sc in the Sc concentrate originates from augite, hornblende, and aluminosilicate. Magnesium chloride and the Sc concentrate were placed in a roasting furnace for chloridizing roasting, causing the partial chlorination of Sc to ScCl3. Sc was extracted from the roasted ore using hydrochloric acid leaching. Sc extraction indices demonstrated 95.12% Sc2O3 leaching efficiency and 0.0011% Sc2O3 content in the acid leaching residue, clearly indicating the extraction of Sc. No noticeable peak of Sc was observed in the spectrum of the acid leaching residue. Most of the Sc in the roasted ores was dissolved as Sc3+, and it entered the liquid phase. The main minerals in the acid leaching residue were Mg2SiO4, CaTiO3, and Fe2SiO4.

Similar content being viewed by others

References

Y. Moëlo, Y. Lulzac, O. Rouer, P. Palvadeau, É. Gloaguen, and P. Léone, Can. Miner. 40, 1657 (2020).

W. Ding, J.H. Xiao, Y. Peng, S.Y. Shen, T. Chen, K. Zou, and Z. Wang, Miner. Process. Extr. Metall. Rev. (Crossref, 2020).

A. Akcil, N. Akhmadiyeva, R. Abdulvaliyev, M.P. Abhilash, and P. Meshram, Miner. Process. Extr. Metall. Rev. 39, 145 (2018).

J.H. Xiao, W. Ding, Y. Peng, T. Chen, and K. Zou, Metals 10, 960 (2020).

M.O. Barsukova, S.A. Sapchenko, D.N. Dybtsev, and V.P. Fedin, Russ. Chem. Rev. 87, 11139 (2018).

M.Z. Bian, X.S. Huang, M. Mabuchi, and Y. Chino, J. Alloys Compd. 818, (2020).

J. Biswal, S. Goswami, H.J. Pant, Y.R. Bamankar, T.V.R.V. Vittalrao, R.K. Upadhay, and A. Dash, Ind. Eng. Chem. Res. 55, 3 (2016).

C.R. Borra, J. Mermans, B. Blanpain, Y. Pontikes, K. Binnemans, and T. Van Gerven, Miner. Eng. 92, 152 (2016).

E.M. Peters, S. Kaya, C. Dittrich, and K. Forsberg, J. Sustain. Metall. 5, 48 (2019).

J.H. Xiao, Y. Peng, W. Ding, T. Chen, K. Zou, and Z. Wang, Processes 8, 365 (2020).

W. Ding, J.H. Xiao, Y. Peng, S.Y. Shen, T. Chen, K. Zou, and Z. Wang, Physicochem. Probl. Miner. Process. 56, 125 (2020).

R. Francis and S. Clarke, Corrosion 76, 707 (2020).

J.H. Xiao, W. Ding, Y. Peng, Q. Wu, Z.Q. Chen, Z. Wang, J.M. Wang, and T.F. Peng, J. Min. Metall. Sect. B. 53, 305 (2019).

S.S. Fujii, E.C. Suzuki, N.M. Inazu, S.T. Tsubaki, J. Fukushima, H.S. Takizawa, and Y.J. Wada, Sci. Rep. 10, 13766 (2020).

G.H. Li, Q. Ye, B.N. Deng, J. Luo, M.J. Rao, Z.W. Peng, and T. Jiang, Hydrometallurgy 176, 62 (2018).

R. Jha and G.S. Dulikravich, Comput. Mater. Sci. 182, (2020).

O. Jankovský, D. Sedmidubský, P. Šimek, K. Klímová, D. Bouša, C. Boothroyd, A. Macková, and Z. Sofer, Phys. Chem. Chem. Phys. 17, 25272 (2015).

J.H. Xiao and Y.S. Zhang, Processes 8, 200 (2020).

J. Kim and G. Azimi, RSC Adv. 10, 31936 (2020).

G.V. Kostikova, I.E. Mal’tseva, and V.I. Zhilov, Russ. J. Inorg. Chem. 64, 277 (2019).

V.I. Kuzmin, V.N. Kuzmina, N.V. Gudkova, and D.V. Kuzmin, Hydrometallurgy 180, 221 (2018).

S.C. Li, S.C. Kim, and C.G. Kang, Miner. Eng. 137, 200 (2019).

B. Onghena, C.R. Borra, T. Van Gerven, and K. Binnemans, Sep. Purif. Technol. 176, 208 (2017).

V.N. Rychkov, V.S. Semenishchev, M.A. Mashkovtsev, E.V. Kirillov, S.V. Kirillov, G.M. Bunkov, and M.S. Botalov, J. Radioanal. Nucl. Chem. 310, 1247 (2016).

M. Sharaf, W. Yoshida, F. Kubota, and M. Goto, Solvent Extr. Ion Exch. 36, 647 (2018).

P.R. Smirnov and O.V. Grechin, Russ. J. Phys. Chem. 91, 517 (2017).

J.H. Xiao, W. Ding, Y. Peng, T. Chen, K. Zou, and Z. Wang, Minerals 10, 352 (2020).

J.C. Dong, Y.G. Wei, S.W. Zhou, B. Li, Y.D. Yang, and A. Mclean, JOM 70, 2365 (2018).

T.N. Simonova, A.N. Fedotov, and N.V. Alemasova, J. Anal. Chem. 73, 18 (2018).

A.G.O. Souza, P. Aliprandini, D.C.R. Espinosa, and J.A.S. Tenório, JOM 71, 2003 (2019).

Acknowledgements

This work was funded by the Sichuan Science and Technology Program (Grant Nos. 2021YJ0057, 2021YFG0268, 2019FS0451, and 2019FS0452), the Research Fund Program of Innovation Center of Rare Earth Resources Development and Utilization, China Geological Survey (Grant No. 2021XTZX01), Key Laboratory of Guangdong Provincial Key Laboratory of Radioactive and Rare Resource Utilization (Grant No. 2018B030322009), and the Research Fund Program of Key Laboratory of Sichuan Province for Comprehensive Utilization of Vanadium and Titanium Resources Foundation (Grant No. 2018FTSZ35).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xiao, J., Zou, K., Chen, T. et al. Extraction of Sc from Sc-Bearing V–Ti Magnetite Tailings. JOM 73, 1836–1844 (2021). https://doi.org/10.1007/s11837-021-04665-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04665-3